RBH Sound SX-12 Subwoofer Review with Measurements

- Product Name: SX-12 Subwoofer

- Manufacturer: RBH Sound

- Performance Rating:

- Value Rating:

- Review Date: October 31, 2006 08:25

- MSRP: $ 1,099

- 12” forward firing driver

- Down firing, flared and dimpled 4” port

- Amplifier: 350 watt

- Low Pass Crossover: Variable 40-150Hz

- Frequency Response: 27-150Hz +/-3dB

- Finishes: A large selection of high quality veneers (Review unit was black ebony)

- Dimensions (H/W/D): 19.625” x 17.7” x 21.125”

- Weight: 53 lbs.

- Warranty: 5 years (Driver and cabinet) / 1 year (Electronics)

Pros

- Nice aesthetics

- Simple set-up and integration

- "Bulletproof" design

- Very Musical

Cons

- Limited ultra-low frequency extension

RBH Sound SX-12 Subwoofer Video Review

RBH Sound SX-12 Video Review

Continue to the next page for our full written report with measurements of the RBH Sound SX-12 Subwoofer.

RBH Sound SX-12 Introduction

RBH Sound is a

privately held loudspeaker company, in operation for 35 years now, that

manufactures and designs its own products from the ground up. The company was

founded in 1976 and initially was an OEM manufacturer with which some rather

famous audio companies contracted work and consultation from. In 1986 RBH

decided to relocate to Utah and strike out in a new direction to establish the

brand as an audio manufacturer of finished products in its own right. 25 years

later RBH is still going strong and has an extensive line up of products. Today

we will take an in depth look at a powered subwoofer model from their Signature

SX series, the SX-12 which is a 350 watt bass reflex design based around a 12”

driver.

Check out the full video review (including the complete text transcript)

Unpacking and Initial Thoughts

The SX-12 arrived via FedEx and upon arriving home and seeing the condition of the box I noted that it was a little worse for wear. After fully unpacking the SX-12, which was a quick, easy exercise, I noted that two of the mounting tabs were broken off on the right side of the grill and that the back of the enclosure had sustained a dent in the back corner corresponding with some damage to the outer box. This sub was obviously shipped around a lot before I received it, most recently to the Audioholics HD video production studio for a video review shoot. It appeared that at some point the SX-12 had been dropped on the edge of the box. At least that would be my guess as to what happened. At that point I quickly examined the amplifier and woofer and noted that all seemed ok with them and that there seemed to be no structural damage to the enclosure. A couple of snapped off grill inserts and a ding on the enclosure seemed to be the extent of the damage. At that point I plugged the SX-12 in to determine that it was still in working order. It was. I made report of the subs arrival condition and decided that despite the minor cosmetic issues the sub was still in plenty good working condition to continue with the review. Despite the damage to the SX-12 the packaging seemed to be pretty standard and would usually be adequate. The SX-12 is what I would consider as a moderate or average size for a powered subwoofer and weighs in at 53lbs so it isn’t in need of overkill packaging measures. It has the usual thick foam top and bottom protections, a bag for the subwoofer and the cardboard boxing around all of that which is fairly standard for a sub of this size and weight. Contained in the package is the SX-12, the grill and power cord.

With all of that out of the way, the SX-12 looks pretty good in the provided black oak finish with the aluminum driver cone giving it some flash. The graceful curve to the side panels adds a lot to the RBH’s good looks and is also claimed to help reduce internal standing waves. It is funny how something so simple could make such a big difference, but the gentle curve of the side panels on the SX-12 easily take it up an extra notch or two in the looks department differentiating it from just another black cube.

Design Overview

The SX-12 utilizes a nominally 12” driver forward firing in a vented

or bass reflex alignment. The vent in this case is a 4” down firing port which

is heavily flared at both inlet and outlet and also has a dimpled texture

molded into the port flares. This is similar to the surface of a golf ball.

This type of surface is said to maintain laminar air flow at higher speeds and

offer less surface friction to air flow than a conventional smooth surface. The

port is allowed to breathe and held roughly 2” off of the floor by extra tall

rubber feet on the enclosure bottom. In addition this close coupling to the

floor surface in front of the port can help to slightly lower the tuning of the

system by adding to the effective air mass of the port.

The driver utilized in the SX-12 features an aluminum cone, a rubber half roll surround and what appears to be a nominally 2” diameter, single voice coil, centered with a single moderate diameter spider. The single ferrite magnet in the motor is about 6” in outside diameter and 1” thick. The back plate is bumped to provide clearance from bottoming and has a small pole vent with a screen to prevent debris from entering the motor. The assembly is held together by a nice cast aluminum frame. This is not a massive, heavy duty subwoofer driver by the standards of today. This driver appears to be more in the vein of a high fidelity woofer than the high excursion, sub bass air pumps which have become more common in the last decade. RBH does offer a driver and amplifier upgrade as part of their Signature Reference line, but a test unit wasn’t available at the time we reviewed this unit. The driver used in the SX-12/R is much heavier duty and said to offer twice the excursion of the stock unit. The amplifier is also increased to 500 watts. It would be interesting to review the upgraded SX-12R in the future.

The amplifier utilized in the SX-12 is rated at 350 watts and is labeled as a DSA-350. It only offers the most basic features: Gain, phase adjustment, low pass filter adjustment and a toggle switch for selection of on, off, or auto on settings. In addition to the usual unbalanced RCA type connections there are balanced XLR connections which I prefer to use whenever possible. The main power switch, socket for the detachable power cord and a fuse round out the amplifier back panel. The amplifier has no external heat sinks but does have a couple of small ones internally. During the high power outdoor testing the amplifier did get warm to the touch towards the end.

RBH constructed the enclosure for the SX-12 out of 3/4” MDF. The front baffle is countersunk to flush mount the driver and is double layered. The amplifier is not countersunk. The grill is your average black cloth covered affair. Inside the enclosure there is a pair of shelf braces tying the top, bottom and side panels into each other. The port is also flared on the inside of the enclosure and extends within inches from the roof of the enclosure. There is damping material applied on both sides and the top of the enclosure.

RBH Sound SX-12 Listening Session

For all of the listening sessions the SX-12 was placed in the front right corner of the room firing back into the corner about 6 inches from the wall with the port down firing. I have determined this to be the best available single subwoofer placement in my room. Audyssey was run on the system to allow it to integrate the SX-12. This was followed by a check and recalibration of the subwoofer and speaker levels.

Blu-ray:

The Police- Certifiable

After 25 years the Police reunited for this live performance in Brazil. Captured in high definition the audio is mixed surprisingly hot compared to most other concert videos I own and even at a master volume setting of -20 on my receiver the SX-12 was being given plenty of bass information to get a good workout. Stewart Copeland’s performance is stellar as usual, if a bit quirky and his drum kit is punchy and full sounding. The SX-12 provided ample attack and cut as required for Copeland’s kick drum and tom work. Sting’s bass guitar is really loud in the mix here and the SX-12 had no trouble producing the long sustained bass tones with proper power and the occasional section of more subdued playing with fine dexterity. As usual I started to turn up the volume some more towards the end to see how well the subwoofer maintained its sound quality and composure at louder volumes. By the time “Message in a Bottle” was performed I was up to -15 on the master volume. The SX-12 still sounded clear at this level and kept definition to the individual bass tones. The kick drum still had sufficient dynamic contrast to separate itself from the underlying bass guitar. The SX-12 did a fine job enhancing my enjoyment of this concert Blu-ray.

Blu-ray: The Hurt Locker

For the movie portion of the listening session I decided on The Hurt Locker. The audio engineering for this soundtrack is very high quality and the bass range itself is a difficult test of the dynamics and extension of any subwoofer system. Many of the sections contain very loud and very deep bass frequencies, but others are lower in volume, varied in depth, texture and duration, so there is a good range of material to gauge a subwoofers performance with. One of the first action sections of the movie involves a large bomb explosion which is very loud. With my master volume at -15, I thought that I detected a slight hint of either port noise or overload out of the SX-12 on this part. Later on into the film there is a battle in the desert involving a 50 caliber machine gun, which is home theater demonstration worthy material. Every time the 50 caliber is fired it is accompanied by a loud, wide bandwidth effect with an extreme amount of very deep bass accompanying each shot. The SX-12’s reproduction on this part lacked the power and concussive aspect that I have come to expect from this scene. The very deep bass seemed to be M.I.A. and overall the dynamics of each shot fired seemed to be muted somewhat. It is possible that the SX-12 may have been into its limiter during some of this, but I am not sure. Throughout the rest of the movie there are many more very large explosions and action sequences that require a lot of heavy lifting from the subwoofer. The SX-12 tried valiantly but it seemed to be just a bit overmatched by the large space it was operating in and the huge deep bass transients embedded into this soundtrack. When things weren’t blowing up and the SX-12 had some headroom left over, it did very well reproducing the material presented to it. However I did note that the presence of deep bass seemed to be absent.

RBH Sound SX-12 Measurements and Analysis

The RBH Sound SX-12 subwoofer was measured outdoors sitting on the ground with the microphone placed 2 meters from the front lip of the cabinet pointing at the main driver which was forward firing and with the port down firing. The low pass filter was disabled and the subwoofer volume was set to maximum for all testing, except for those tests purposely conducted to examine the effects of the built in functions. The overall approach to this testing along with the equipment and software used is outlined in the article here.

Powered Subwoofer Testing Outline and Procedures Overview

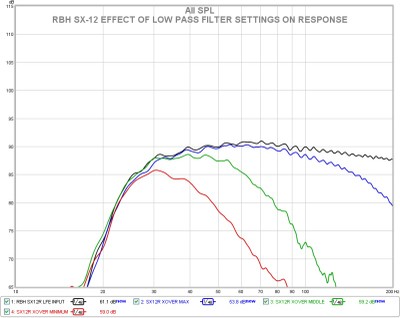

RBH Sound SX-12: Effect of Low Pass Filter Settings

I took a measurement of the RBH with the low pass crossover of the SX-12 bypassed using the LFE input and at maximum, middle and minimum settings to observe its effect on the response shape. This is presented in the graph above. The slope of the SX-12’s low pass filter appears to be 24dB/octave and corresponds very well with the listed 40-150Hz range specified by RBH.

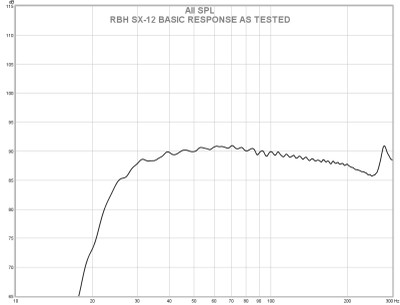

RBH Sound SX-12: Basic Frequency Response as Tested

Above is the response of the SX-12 as configured for most of the measurements. RBH lists the response of the SX-12 as 27-150Hz +/-3dB. The as measured response easily matches and in fact surpasses that specification on both ends of the frequency range. The SX-12 response actually fits into a 25-250Hz +/-3dB window. I discounted the response past 250Hz due to the port resonance at about 280Hz. The SX-12 should have no problems mating with even the most bass shy main speakers. The 36dB/octave roll of below 30Hz indicates that the system port tuning is near the 25-30Hz range and that there is probably a 12dB/octave rumble filter in place to attenuate content below the system tuning point.

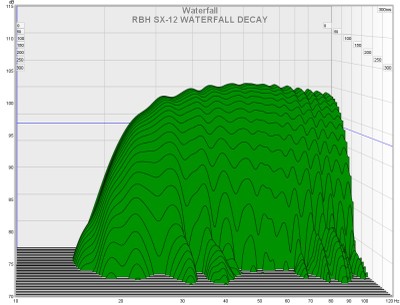

RBH Sound SX-12: Waterfall Decay

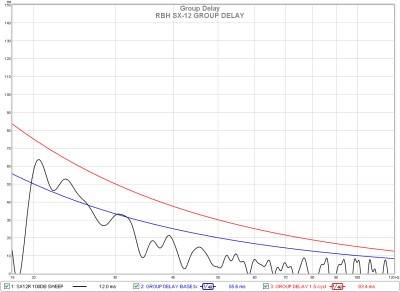

RBH Sound SX-12: Group Delay

The waterfall and group delay plots for the SX-12 show no appreciable issues and are commendably well behaved throughout its entire useful range of operation. There is a slight amount of prolonged energy between 20 and 30Hz but it just barely breaks 1 cycle of delay. This is a good showing for a bass reflex design.

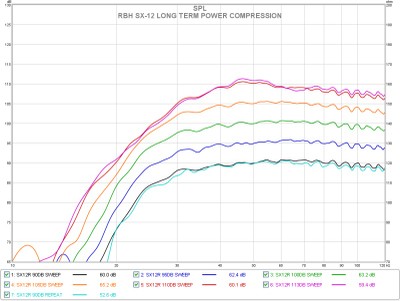

RBH Sound SX-12: Long Term Power Compression

The results of the long term power compression sweeps show that the SX-12 maintains its response shape well up through the 105dB sweep, but has entered significant compression by the 110dB level. Increasing the level further to what would nominally correspond to 113dB at 50Hz resulted in virtually no further output. The SX-12 did exhibit some port wind noise on the last two sweeps and also some minor overload type noises below the tuning.

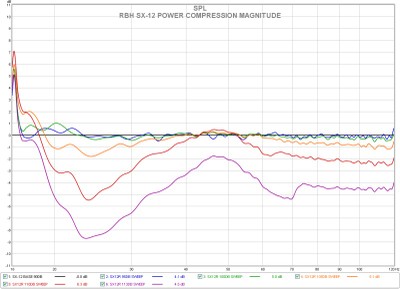

RBH Sound SX-12: Power Compression Magnitude

Looking at just the magnitude of compression occurring during the sweeps we can more clearly see where it is occurring. The large amount shown centered near 25Hz is probably mostly attributable to compression and overload of the port. This is typical for ported systems. The negligible increase in output on the 113dB sweep indicates that the SX-12’s limiter was already engaged during the 110dB sweep level.

RBH Sound SX-12: Maximum Long Term Output Level

The maximum long term output achieved by the SX-12 falls into the lower middle range of all subwoofers tested and the response maintains a +/-3dB shape from about 30-120Hz.

RBH Sound SX-12: 100, 105, 110dB Sweep THD Comparison

The distortion results captured during the power compression sweeps for the SX-12 show solid performance up until the maximum output level is reached. THD is below 10% from 30-120Hz and shows the typical bass reflex distortion increase below the system tuning. The double dip aspect to the THD profile is typical for a bass reflex alignment with the low points in distortion usually corresponding to the tuning and the peak in impedance higher in the pass band.

RBH Sound SX-12: CEA2010 2 meter Groundplane RMS Results

RBH Sound SX-12: CEA2010 2 Meter Groundplane RMS Comparison

CEA2010 Results

The CEA2010 maximum passing results for the SX-12 show that it is in the lower middle range of all subwoofers that have been tested thus far. The RBH exhibits good headroom at the 31.5Hz band recording 108dB and the bands above that point are all in excess of 111dB, but offers little useable output below 30Hz. The SX-12 recorded a maximum a passing output of 98dB at 25Hz but could produce up to 100dB if the distortion is ignored completely. The SX-12 is amplifier limited at 31.5Hz and above, but is distortion limited below that point. With some room gain factored in the useable lower limit of the SX-12 is likely to be in the 25Hz range in room.

RBH Sound SX-12 Conclusion

Having

gotten to know and tested the RBH SX-12 over the course of a week or so I can

say that in some ways it is very good and in others there is some room for

improvement. With its curved sides, large dimpled port flare and aluminum

driver cone it is a sharp looking unit. I imagine the other available finishes

look even better. The distortion performance is pretty good all of the way up

till the limiter kicks in, as is the extended upper frequency response which is

useable up until almost 250Hz. Those factors plus the well damped alignment are

contributing reasons to why the SX-12 sounded really good with music or

material not containing super deep bass at woofer bottoming levels. However the

limited extension and low bass output headroom mean that the SX-12 isn’t as

suited to high output home theater low frequency effects in a large room. The

majority of music contains little energy below 30Hz but movie soundtracks have

content below 30Hz regularly and often at much higher intensity. The SX-12 is

well behaved when presented with this material for the most part, but it will

make some minor distress noises if overdriven below its effective pass band. If

I had to guess I would speculate that RBH puts far more emphasis on performance

with music than home theater during their development. That is pure speculation

on my part though. The SX-12 is not a one note, booming contraption that is for

sure. The SX-12 is notably lacking the built in DSP processing and other bells

and whistles that many subs are now coming to market with. For some this might

be considered a good thing or not. Personally I don’t place a whole lot of

weight on the inclusion of remotes, built in EQ or other such features, but

some people will.

The price and size class that this subwoofer finds itself in is hotly contested and in order to separate yourself from the pack you need to distinguish your product in some way. The RBH SX-12 does that by eschewing the extra “fluff” and add ins that some other subwoofers have in favor of a simpler more streamlined model, a finer appearance than most and focusing on getting the performance basics right, which they have achieved largely. If it just had better extension and a little extra low end grunt for home theater, especially for a subwoofer of this size. With that caveat out of the way, RBH has a well thought out and executed product that is: Simple to use, looks great, performs well and should integrate well with even the smallest mains. To audition the SX-12 or other RBH products visit the RBH Sound web site and locate an authorized dealer in your area.

The RBH SX-12 conditionally achieves the Audioholics Bassoholic Large room rating (2dB shy at 25Hz only), which means that this sub is recommended as maintaining adequate headroom in medium sized spaces of between 3,000 and 5,000 cubic feet and/or users who usually listen at a moderate volume level. For those with rooms on the larger size approaching 5,000 cubic feet, we recommend upgrading to the SX-12/R which features RBH's HP driver and 500 watt amplifier. The SX-12/R offers about 4dB more output compared to the standard SX-12 subwoofer which should help fill larger spaces with more authoritative bass.

For further information in how we make these recommendations see the full article here.

See: Audioholics Subwoofer Room Size Rating Protocol

RBH Sound SX-12 Review

MSRP: $1,099

Toll Free (800)

543-2205

E-mail: Info@RBHSound.com

The Score Card

The scoring below is based on each piece of equipment doing the duty it is designed for. The numbers are weighed heavily with respect to the individual cost of each unit, thus giving a rating roughly equal to:

Performance × Price Factor/Value = Rating

Audioholics.com note: The ratings indicated below are based on subjective listening and objective testing of the product in question. The rating scale is based on performance/value ratio. If you notice better performing products in future reviews that have lower numbers in certain areas, be aware that the value factor is most likely the culprit. Other Audioholics reviewers may rate products solely based on performance, and each reviewer has his/her own system for ratings.

Audioholics Rating Scale

— Excellent

— Excellent

— Very Good

— Very Good

— Good

— Good

— Fair

— Fair

— Poor

— Poor

| Metric | Rating |

|---|---|

| Bass Extension | |

| Bass Accuracy | |

| Build Quality | |

| Fit and Finish | |

| Ergonomics & Usability | |

| Features | |

| Dynamic Range | |

| Performance | |

| Value |