Status Acoustics Titus 8T Floorstanding Speaker System Review

- Product Name: Titus 8T Floorstanding Speaker

- Manufacturer: Status Acoustics

- Performance Rating:

- Value Rating:

- Review Date: December 10, 2012 17:00

- MSRP: $ 50k/pair

-

Product Description: Passive Modular 3-way design with ported bass module and sealed two-way satellite module

-

Frequency Response: 20Hz to 40kHz +-3dB

-

Sensitivity: 93dB (2.83V/1 meter)

-

Recommended Power: 50 - 1,000 watts

-

Drive Units: 1 - 1” (26mm) Pure Beryllium Dome Tweeter, 4 - 6.5” (165mm) Beryllium Alloy Cone Midrange, 3 - 10” (254mm) Aluminum Cone Woofers

-

Crossover Frequencies: 120Hz, 2,700Hz

-

System Impedance: 4-ohms

-

Wiring Capability: Tri-amp / Tri-wireable

-

Dimensions: 66” H x 27” W x 32” D (1,676mm H x 687mm W x 813mm D)

-

Weight: 345 lbs (143 kg)

Pros

- Unparalleled audiophile performance

- Sets an industry benchmark in cost no object loudspeaker design

- Unique design breaks away from traditional box cabinet look

- Speakers you can keep for life

Cons

- Uber expensive

- Very heavy

- Spoils your sonic pallet

- Challenging load impedance

Status Acoustics 8T Introduction

It isn't often that I review a product that fundamentally changes the way I listen and experience audio. Status Acoustics, the premier line of RBH Sound, has managed to do just that with their new flagship Titus 8T floorstanding loudspeaker system. The Status line-up is RBH's premier speaker brand which is fully designed and manufactured in Layton Utah. It's been nearly a decade since RBH Sound produced their Status Acoustics series of loudspeakers which I was introduced to with the wonderful Decimo's that still serve as my reference bookshelf speaker to this day. Since I've taken delivery of the Status 8T system, I've given up my nightly XBOX online gaming addiction and almost completely abandoned multi-channel music, let alone movie watching. The Status Acoustics 8T speaker system is truly transformational. Read on to find out why.

Status Acoustics 8T Video Review

The Status Titus 8T's showed up at my place in huge crates with a combined weight of 1,200 lbs that took the place of my car while I waited for help to unbox them. This was no easy chore, but what is when you're constantly seeking the very best in any hobby?

The

Status 8T speaker system is a modular design consisting of separate

left and right satellite and bass modules connected via a very clever

bracketing system. Each bass module houses three (3) high excursion

10” aluminum drivers and each satellite module contains four (4)

6½” Beryllium midrange drivers and a 1” Beryllium dome tweeter.

Status Acoustics shipped the 8T's with the bracket that holds the

speakers together connected to each bass unit.

Fully assembled, the 8T weighs 345 lbs per speaker. The bass module weighs 175 lbs. and the satellite portion another 135 lbs. The bracket that holds them together weighs 35 lbs. It took four of us to hoist these speakers up my flight of steps to the Audioholics Showcase Theater room. The entire process made me question whether I will attempt to review such a large speaker ever again - reviewers in single-story houses definitely have the advantage here.

The primary design goal of the 8T speaker system, per Status Acoustics, is to produce true-to-life natural sound with realistic imaging characteristics and unrestricted dynamic range, while maintaining a small visual profile that is also aesthetically pleasing. Just what did they do to attempt to make this speaker system live up to such a claim? Let's take a tour of its design to find out.

Status Acoustics Titus 8T Floorstanding Speaker System Design Overview

In order to truly appreciate the engineering marvel that the Status Acoustics 8T modular tower speaker system is, it's necessary to break down all of its various components.

The

Bracket

Probably the most important and time-consuming aspect of the design that allows the 8T to work successfully as a modular system is the bracket. The bracket allows the top satellite module housing the midrange and tweeter to be suspended above the bass module in a manner that isolates them from each other acoustically, yet creates a striking visual appearance where the top section appears to “float” above the bass module when viewed from the front. This was no small feat, given the fact that the satellite speaker being suspended weighs 135 lbs.

Project Manager Allen Lewis and loudspeaker Design Engineer Shane Rich spent many hours over the last few years bouncing ideas off each other, and discussing how they could design a modular system which would improve on the one-piece design concept they originally had. A new modular design would help address production issues and, at the same time, make the speaker easier to ship. This was a relief to me as, had Status Acoustics instead proceeded with a one piece design, I would have never been able to review it.

The bracket had to be hollow, rigid, and inert in order to not transfer any mechanical vibrations. It also needed to serve as a conduit for the jumper cable connecting the bass and satellite modules. While this could be accomplished with any cable of your choice, Status Acoustics paired up with Kimber Kable to design a specific 7 foot jumper based on their Monocle speaker cable. This optional accessory will run you a cool $1000, which may be the most expensive jumper cable ever conceived, but it really dresses up the speaker nicely and provides the snuggest lowest resistance connection possible.

The

Cabinets

In all my years reviewing loudspeakers, I've never seen more rigidly constructed cabinets. The satellite module is so dense and heavy that you know, just from picking it up, that this is no ordinary speaker. A knock test reveals a deadening thud, almost like you're rapping on a solid slab of granite. Peering inside the satellite speaker, I began to understand why this was the case. Status Acoustics utilized a proprietary method of bonding multiple layers of 1” HDF to effectively make a solid cabinet. This expensive process gives the 8T its unique look while also allowing the cabinet wall thickness to be varied without the limits typically imposed by traditional panel construction, allowing for more extensive internal bracing. The end result of this method is cabinets that are more acoustically inert for optimum sound quality. Cabinet panel resonances are greatly reduced with this design, resulting in superior definition throughout the mid and bass frequency range.

For

the satellite cabinet, each driver is completely isolated inside

their own chambers. This isn't done via cheap plastic cups like

with lesser designed speakers. These are effectively solid wood

chambers bored out from the multiple bonded HDF layers customized for

each driver. This is done not only to physically and mechanically

separate each driver but to reduce standing waves in the chambers. In

addition, there are no parallel walls inside the cavities, which

further reduces standing waves. In conjunction with this no holds

barred construction method, Status Acoustics employed special damping

materials to greatly reduce backwave energy which would ordinarily

radiate back through the cone of the driver.

For

the satellite cabinet, each driver is completely isolated inside

their own chambers. This isn't done via cheap plastic cups like

with lesser designed speakers. These are effectively solid wood

chambers bored out from the multiple bonded HDF layers customized for

each driver. This is done not only to physically and mechanically

separate each driver but to reduce standing waves in the chambers. In

addition, there are no parallel walls inside the cavities, which

further reduces standing waves. In conjunction with this no holds

barred construction method, Status Acoustics employed special damping

materials to greatly reduce backwave energy which would ordinarily

radiate back through the cone of the driver.

The subwoofer module has a spacious 5.5 ft^3 internal volume shared among the three bass drivers which also has non-parallel walls to reduce standing waves. A special damping compound (which Status says is superior to polyfil and fiberglass due to a higher absorption coefficient at bass frequencies) amply fills the enclosure to absorb acoustic backwave energy and in effect causes the bass drivers to see an even larger enclosure which extends the systems usable frequency response.

The Status 8T bass modules are 4th order rear vented enclosures using large flares on both ends of the 4” diameter ports each about 18” in length. The ports are dimpled similar to the ports of upper end B&W speakers to further reduce turbulence. Having multiple bass drivers and multiple surfaces of radiation allows for increased modal density which produces more uniform bass loading into the room compared to a single driver design with the port on the same face as the driver.

Status 8T Bass Module with Dual 4” Dimpled Ports

The front and back cabinet baffles for both the bass and satellite modules are quite unique. They are made of an acrylic polymer which has superior acoustic damping properties compared to wood baffles. By using the combination of materials (acrylic polymer baffles combined with layered HDF in the cabinets) this virtually eliminates colorations caused by cabinet resonances.

This speaker employs many of the methods we discussed in: Identifying Legitimately High Fidelity Loudspeakers - Cabinets Myths & Facts and Detailed Loudspeaker Cabinet Bracing.

Status Acoustics Cabinet Finish Options

Cabinet Finish Options

Status Acoustics offers over 30 real wood veneers with a clear lacquer finish. They even offer a premium carbon fiber finish that adds a whopping $15k estimated price increase. But this shouldn't come at a surprise to any exotic car loving fans wanting their favorite car in this type of finish. My review samples were finished in Classic Mahogany.

The Driver Topology

The Status 8T system employs an MMTMM driver arrangement which basically sandwiches a tweeter between the vertically oriented midrange drivers. Status Acoustics takes this traditional design approach up a notch by incorporating an additional top and bottom midrange driver which improves control of vertical dispersion, lowers system distortion and increases dynamic range. All of this can be attributed to how the speaker system produces a more palatable sense of realism which I will discuss further in the listening portion of this review. It's been my experience that a vertical MTM sounds more natural, dynamic and lifelike than a conventional MT driver alignment. This type of driver arrangement allows for more control over floor and ceiling room reflections and provides a higher ratio of direct vs. reflected sound at the listening position. In a very basic sense, multiple vertical oriented drivers operating in the same frequency range behave as if they were a single larger driver of their combined dimensions. Therefore in the vertical plane, the Status 8T has the vertical dispersion characteristic of a huge driver, which is also very narrow. Hence there is very little midrange energy going up to the ceiling or down to the floor and therefore, those destructive, detail-smearing reflections are minimized.

Status Acoustics chose to make the satellite portion of the 8T system a two-way design. They claim it sounds more cohesive with a high quality two-way crossover as opposed to a 2.5-way network. A two-way crossover does not have the additional phase shift between drivers you would get with a comparable 2.5-way network.

Status

Acoustics Titus 8T Front View (left pic: no grilles; right pic: with

grilles)

The left above image shows off the beauty of the drivers of the Status 8T system with the grille covers removed. The acrylic polymer baffle not only aids in performance aspects of the speaker but adds a touch of class to the product commensurate with RBH Sound's “Status” series nomenclature. The right above image shows how equally beautiful the 8T system looks with its magnetic grilles in place. However, any serious audiophile will keep these babies naked for critical listening as well as showcasing the product to visiting friends.

Status Acoustics 8T Grille Covers

The grilles of the Status Acoustics 8T towers are quite impressive. They are constructed of HDF tightly covered with low-loss grille material and well-braced for rigidity. There are a total of 24 high strength neodymium magnets integrated into the front baffles and grilles for each speaker which makes for a very firm and immediate connection if you hold the grille within a few inches from the front baffle. The grilles remain in perfect alignment with the front baffle even if you give them quite a tug.

The Bass Drivers

Each Status 8T bass module comes loaded with three (3) 10” high excursion aluminum cone subwoofer drivers. These drivers feature a 2.5” voice coil and 12.5 lbs heavy duty motor structure with a vented pole piece and aluminum former with the leads sewn into the cone to prevent breaking. The aluminum cone serves as a heatsink to increase power handling. The driver employs a 2.5” diameter 1.3” voice coil and has a 1” peak linear travel. The bumped backplate design eliminates the possibility of bottoming out the driver under heavy excursion.

I torture-tested these subs by running them as the left/right main channels fullrange while directing bass to them from the LFE channel and ALL channels (center + surrounds) set to "small". On bass intense Blu-rays at above reference levels in my large room, I was unable to bottom the drivers or cause any serious audible distress. In fact, I ran out of available amplifier power from my Classe CT-2300 amp (600 watt+ @ 4-ohms) while the Status drivers were still hungry to pump out more SPL's.

Status 10" Aluminum Woofer (left pic); Status 6.5" Beryllium Midrange (right pic)

The Midrange Drivers

Each Status 8T satellite module features four (4) 6½” Beryllium/Aluminum phase plug drivers. The driver basket is a high quality cast aluminum (no cheap stamped metal parts here). Employing Beryllium in the cone improves on aluminum by offering a stiffer, lighter-weight cone with a less pronounced breakup mode that is shifted further beyond the bandwidth in which the driver is being used. Energy storage retention is also reduced. Youngs modulus (a measure of stiffness) is higher with Beryllium, meaning the cone will flex less under stress. The Beryllium alloy cone also produces a more linear transition in the stopband for smoother integration between the drivers. The phase plug reduces moving mass and on-axis beaming and also serves as a heat sink and, to a smaller extent, offers venting for the voice coil. There is also a rubber stopper affixed to the cone to further reduce air turbulence through the gap. A lot of engineering went into this driver, and it certainly shows in droves in performance (see our measurements later). Employing four of these drivers in the design not only expands the soundstage but also assures effortless dynamics in the midrange at all power levels.

The Tweeter

Each Status 8T satellite module features the new Scan-Speak Illuminator Model 6640 tweeter sandwiched in between the midrange drivers. Scan-Speak's unique AirCirc Magnet System optimizes air flow within the chamber by rearranging the traditional magnet structure from a single magnet to an open magnetic circuit comprised of six separate neodymium slugs. This, in combination with the chamber, is said to eliminate the reflections and resonances that compromise the performance of traditional motors.

Scan-Speak 6640 Beryllium Illuminator Tweeter

The 6640 is arguably the finest-sounding dome tweeter on the market, but at a spendy $500 per driver, it's also one of the most expensive. The 6640 has excellent power handling, frequency response and distortion specs compared to the equivalent fabric dome from Scan-Speak. The Beryllium version is said to offer higher resolution, and lower distortion. This is a true Beryllium driver, not a cheap knock off aluminum dome coated in Beryllium for marketing purposes. In my torture tests, I was shocked at just how much power these tweeters could absorb, never losing composure or sounded strained no matter the source or listening level.

There is a 3rd party write up comparing both tweeters (with measurements) here: http://www.audioexcite.com/?p=1953

The Crossover Network

With such a large array of drivers comes a sophisticated crossover network to control it all. Based on my listening tests and measurements, I was actually quite flabbergasted at how well Status Acoustics managed to integrate all of the drivers using passive networks.

The subwoofers in the bass module utilize their natural rolloff for several octaves before employing a 2nd order electrical lowpass filter. This allows for the best possible integration between the bass and satellite modules. The midrange drivers use an asymmetric bandpass filter to effectively filter bass frequencies for increased dynamic range while also seamlessly integrating with the tweeter. The tweeter utilizes a 4th order HPF @ 2500Hz. This ensures increased power handling and better integrates the tweeter with the summed response from the midrange drivers.

Status Acoustics Crossovers: Tweeter HPF Left Pic; Midrange BPF (Right Pic)

LPF Bass Module on a schnazzy background

The 8T crossover network employs some of the finest components available, regardless of price. Ultra high quality Jensen foil inductors are used in the network to minimize losses and ensure uncompressed sound at any power level since the coils will NOT saturate within the output capabilities of the loudspeakers. High voltage, tight tolerance Kimber and Solen polypropylene capacitors are used throughout the network. You won't find any electrolytic capacitors in this baby.

The subwoofer inductor is a large 2.5 mH 14AWG toroidal core with very high power handling and extremely low DCR (handles 700 Watts continuous at 500Hz where the speaker is already rolled off). This ensures no saturation at all within bandwidth used at any power level.

Although the midrange crossover pictured above shows a stack of ceramic resistors, the actual product crossover of the Status 8T system uses no resistors in the network at all. Status engineers were able to completely eliminate the need for resistors during the final design phase after upgrading the damping material and doing final testing. Because there are no resistors used in the crossovers that are in series with the drivers, there is no chance of compression caused by overheating of resistive elements at high power levels.

The Status 8T speakers are all internally wired with approximately 50ft of Kimber 4TC high performance speaker cable. Given the number of drivers that are driven in parallel in the speaker system, the net harness size is equivalent to a 5AWG conductor.

The crossover networks are all point-to-point soldered to minimize losses by providing the least resistive path with the fewest connection points between components. All of the crossovers are hand-built by their senior techs and special care is taken to ensure components are properly soldered directly together vs. through a PCB.

Status Acoustics engineers considered offering an active crossover network for the 8T system but found there to be no discernible benefit in doing so given the high quality of parts and meticulous design of the passive networks.

The Speaker Connection Scheme

A total of 16 WBT Platinum binding posts are used for each pair of speakers. Combined with the Kimber Kable 4TC internal wiring, that's over $2,600 worth of cables and terminals for this speaker system alone! The WBT platinum connectors are unlike any other speaker connector we've seen. Crafted like fine jewelry, their function is simple, providing the best possible connection between the speaker and the speaker cable. They allow you to lock down spade-terminated speaker cables and banana plugs simultaneously to each connector by simply twisting the dual independent barrels.

There are two sets of binding posts for the satellite module and two sets for the bass module as well. The bottom terminals of the bass module are used as inputs from the amplifier and the top terminals serve as the HPF to the satellite system... Well, at least in my pair. Status Acoustics later informed me that they decided to move the HPF to the satellite module to offer more connection options for those desiring to use this speaker system for dual two-channel and multi-channel applications. So production units now see the top and bottom terminals of the bass module as completely isolated which can be jumpered via the included WBT straps for a single amp connection or the top terminals of the bass module can be used as a secondary input in conjunction with the custom designed Kimber Monocle jumper cable to the satellite module for bi-amping.

Status Acoustics 8T Satellite Terminals (left pic) Bass Module Terminals (Right pic)

Listed below are some possible connection scenarios the customer may configure their 8T system depending on their application. You can skip this portion of the review and come back to it as a reference when you get ready to connect your pair into your system :)

Single Amp Mode:

In a single amp configuration, you can simply jumper the top and bottom terminal connections of the satellite speaker with the bottom terminals of the bass module. The amplifier then gets connected to the bottom terminals of the bass module only leaving no connection to the top terminals of the bass module. For an optional $1000, the customer can purchase a custom built Kimber cable jumper (based on the Monocle design) that properly connects the 8T speaker in this fashion.

Bi-Amp Mode:

In Bi-amp mode, the user attaches one amp to the top connections of the bass module and jumpers it to the top/bottom terminals of the satellite speakers while feeding the second amp to the bottom terminals of the bass module. The first amp will power the satellite speaker while the second amp would power the bass module in this connection scheme.

Tri-Amp Mode:

In Tri-amp mode the user attaches one amp to the top connections of the satellite module, a second amp to the bottom connections of the satellite module and the third amp to the bottom portion of the bass module leaving the top portion of the bass module unconnected. The first amp will power the tweeter, the second amp would power the midrange section and the third amp would power the bass module in this connection scheme.

Home Theater Mode:

In a home theater configuration, the user may wish to experiment with running the satellite module full-range as the main channels, and the bass modules as dedicated powered subwoofers. This can be accomplished by connecting an external amp to the bottom connections of each of the Status 8T bass modules fed directly to the A/V processor's subwoofer output/LFE channel. It can be advantageous to connect the Status 8T speaker like this if you want the sub channel and LFE info routed to the bass modules and/or if you are integrating other powered subs into your system, since all subs will now get identical signal and LFE info. The downside is that you can potentially compromise how the system integrates for critical two-channel operation, since it was designed to be played full-range with the internal passive crossover networks.

Status Acoustics Titus 8T Set-Up & Sound Quality

Let

me reiterate that it took four of us to haul the 8T speaker system up

my flight of steps to the Audioholics Showcase Theater Room - and

that was moving them as separate pieces with the bracket attached to

the bass module. Assembling the 8T system once moved upstairs was

pretty easy. By laying the system on the floor, we bolted each

satellite speaker to the bracket of its corresponding bass module and

then lifted it up from the ground from the top. A speaker this

heavy and massive needs no outriggers or feet but we placed 2”

vinyl discs under the bass module so it would be fairly easy to move

the speaker system into position.

Let

me reiterate that it took four of us to haul the 8T speaker system up

my flight of steps to the Audioholics Showcase Theater Room - and

that was moving them as separate pieces with the bracket attached to

the bass module. Assembling the 8T system once moved upstairs was

pretty easy. By laying the system on the floor, we bolted each

satellite speaker to the bracket of its corresponding bass module and

then lifted it up from the ground from the top. A speaker this

heavy and massive needs no outriggers or feet but we placed 2”

vinyl discs under the bass module so it would be fairly easy to move

the speaker system into position.

We placed the left/right speakers about 3 1/2ft from the back wall and 10ft apart with the primary seating area about 13ft away. We found only a modest amount of toe-in was needed for these babies to really work their magic in my listening space. In fact, I’d guesstimate it was about 10 degrees of toe-in that did it. From the seated position, this also made the connection bracket disappear giving the illusion that the satellite module was floating above the bass module. Very cool effect!

We tested the Status Acoustics 8T speakers with all of the best gear available to us. We broke this into two separate systems with the dedicated two-channel system consisting of a Marantz PM-11S2 Preamp, Pass Labs X350.5 two-channel amplifier, a Marantz TT-15S1 turntable and analog balanced outputs of the Oppo BDP-95 Universal Blu-ray player as the sources. The second system consisted of the Denon AVP-A1HDCI A/V processor, Denon POA-A1HDCI multi-channel amplifier, Classe CT-2300 two-channel amplifier and the Oppo BDP-95 Universal Blu-ray player via the HDMI output. Speaker cables were all Kimber 8TC and interconnects were Bluejeans Cable 1694 COAX and balanced cables. The listening space is a 6,000 ft3 room that is moderately acoustically treated, courtesy of Auralex Acoustics.

Assembling the Status 8T System

The Status 8T system had to be assembled face down. Once the bracket was secured on the bass and satellite modules, we lifted them up from the top and slid them into position.

Status Acoustics 8T & 8C Speaker System installed in Audioholics Showcase Theater Room

Listening Tests

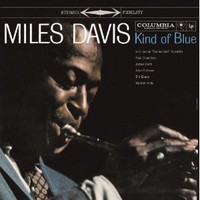

LP:

Miles Davis: Kind

of Blue (180G)

Despite this being a recording from 1959, “Kind of Blue” is recognized as a benchmark for vinyl even by today’s standards and is the best selling jazz album of all time. Accompanying Miles are jazz legends such as Bill Evans on piano and John Coltrane on tenor saxophone. This album is based on modality and was recorded live in the studio with little to no rehearsal, making it almost entirely improvisational. Track #1 “So What” sets the tone for this album, which is just a feel-good laid back aura that is best accompanied by a good glass of red. Jimmy Cobb’s cymbal brushes were delicate and airy while the back and forth between Miles on trumpet and Coltrane on sax was exhilarating. It was hard to believe such an old recording on vinyl had so much dynamic range, seemingly more so than the majority of CD’s recorded today. The Status 8T system produced true to life SPL and realism on this recording. Closing my eyes, I really felt like I was in a jazz cellar in NYC listening to this sextuplet grace me with their phenomenal performance. Track #2 “Freddie Freeloader” is my favorite song on the whole album. It just oozes coolness and if you’re foot isn’t tapping on this tune, someone needs to check your pulse. Bill Evan tickles the ivories with a surgeon’s precision. I got instant goose bumps when Miles’ trumpet kicked in. I just couldn’t get over how authentic and vivacious it sounded, especially when Coltrane answered back in his solo. I was truly getting that “better than being there” experience found only from properly setting up and pairing the very best electronics and loudspeakers in a great sounding room with exceptional source material. The Status 8T speakers were born to play Miles and I felt him smiling down at me at times during my listening session.

I’ve always liked hearing Richard Marx songs on the radio, but never purchased any of his albums because I felt his stuff was a bit too poppy and overplayed. When my wife bought the LP version of his self titled album, I figured I’d give it a shot. I was pretty floored not only by the musical content of this LP, but its sound quality. Side 2 contained songs rarely (if ever) played on the radio and they were much harder hitting than his more well-known radio pop songs. Track #5 “Have Mercy” starts out with some great drumming and a catchy hard rock guitar theme. This song just rocks and begs to be played loudly. Richard’s voice came through very vibrantly and the band just sounded excellent together. This is power rock at its finest and something hard to find today from mainstream music. Although it sounded a bit edgy at high listening levels, it was never fatiguing or overly bright. In fact, I recently went to his solo concert in Clearwater Florida and heard the same tonal characteristics in the upper midrange from his voice. In comparison to the live performance, the Status 8T system was recreating a true to source reproduction of Richard’s vocals. I felt like I was thrust into a live performance with the music enveloping me, despite the fact that I was listening in two-channel. Track #6 “Remember Manhattan” produced a big WOW effect for me. I didn’t know vinyl could produce so much deep and enveloping bass and certainly not from an album like this. But here I was engulfed with chest pounding bass providing the framework for this awesome song. Energetic, bold, lifelike, the Status 8T system powered by the Pass Labs amplification was pure perfection. If you’re not a Richard Marx fan, I can assure you will be after hearing the entire second side of this album. Check it out!

SACD:

Rebecca Pidgeon - The

Raven

Although Rebecca Pidgeon’s lyrics are a bit obscure, this is a sonic gem produced by Chesky Records and recorded by Bob Katz. In my opinion, getting the critical midrange correct in a loudspeaker system is often the most challenging and neglected task. Some manufacturers just don’t understand that if female vocals don’t sound right, than the speaker will never sound like a convincing reproducer of music. Track #3 “The Raven” showcased Rebecca's angelic voice. The Status 8T reproduced concise resonance cues giving me a great mental picture of the piano playing in a room with wooden floors. You could hear the microphone pick up of background noises distinctly thanks to the exceedingly revealing nature of the Status 8T system. The vocals didn’t sound like they were boxed in like I’ve typically heard on other loudspeakers. Instead, her voice just poured out into the room as if she was standing front and center. There was no hint of chestiness or cupped hands like I’ve heard on so many other speakers playing back this SACD. Track #5 “Grandmother” is a really weird song but it kinda grows on you with each listen. Rebecca seduces you with her vocals and the 8T’s showed off the range in her voice unlike I’ve heard with any other speaker system. The piano emanated so much warmth and presence in the room that just didn’t sound like it was being played through a speaker system. Track #12 “Spanish Harlem” is not only my favorite track on this record but it’s also my favorite version of this song. This song put forth a very three-dimensional soundstage wider and with more depth than I ever remembered hearing. I was amazed by the tonal consistency of Rebecca’s voice when I moved my head side to side. The Status 8T system provided very uniform and even coverage to my entire listening area. I didn’t just need to sit in a targeted sweet spot to get great imaging and vocal clarity. Wow!

SACD: Grover Washington JR – Prime Cuts

I’m not even sure how I acquired a copy of this rare SACD but it’s a sonic masterpiece and a must have in your collection if you’re serious about sound and a jazz aficionado like myself. Track #1 “Take Five” has a lot of stuff going on at once, including a deeply rich bass track. Grover’s saxophone came through with pristine clarity while the percussive effects popped out into a very three dimensional landscape. I felt as if the music emanated all around me like I was listening to a multi-channel recording. How the 8T system was able to pull this off was quite magical.

Track #6 “Summer Nights” bore a similar resemblance to “Pyramid” from another great album called Close Up by David Sanborn. I loved the ping pong effect of the percussion instruments between the speakers. The bass modules of the Status 8T system was just pumping out clean deep bass perfectly blended into the rest of system into a very cohesive soundstage. You could hear the triangles slowly decay instead of just sharply fading away, which would otherwise be lost on lesser-designed gear.

This recording has become a multi-channel benchmark for us at Audioholics, but it also has an incredible two-channel layer that is equally impressive. I caution anyone to use the volume control sparingly when playing this disc on their systems as it has extreme dynamic range which most speaker systems are incapable of reproducing at reference volume levels. The vocals were pinned dead center in Track #1 “Sissel” as if I had my center channel engaged. The bass was thunderous and the stereo separation seemed to extend well beyond the width of the speakers. Track #6 “Fredrik Albert” showed off the system's fabulous transient response. The immediacy of the percussion and depth of the bass was epic and not something that can fully be conveyed in writing without actually hearing or feeling for yourself. Even in the two-channel recording of Track #4 “DanceHall”, you’re enveloped in the middle of the room with singers all around you. The percussion was full of life and vibrancy that you rarely ever hear in any recording. Most playback systems are incapable of reproducing the dynamics of this album, but the Status 8T system did this with utter ease. Towards the end of the recording, the electric bass kicked in which literally blew me out of my chair as I was belted with sustained tactile bass that was not only heard but rattled the core of my bones. This disc allowed me to test the limits of my amplification and my hearing because under no circumstance was I able to detect loudspeaker compression or distress. In contrast, the Status 8T’s just begged for more power; something I hoped to oblige in the near future.

CD:

Dire Straits – Brothers

in Arms

As far as mainstream music goes, this 25+ year old recording from Dire Straits is still, in my opinion, one of the finest sounding recordings available on CD. Plus, Tony Levin guest appears on bass which is always a good thing in my book. Originally mastered digitally, this recording lacks compression and thus sounds very analog in nature as a result. Track #4 “You’re Latest Trick” put me in a tranquil mood right from the start, allowing me to hear the more intimate side of the Status Titus 8T system. The trumpets popped out while the electric piano remained in the background. The cymbals were very airy and spacious. Vocals were anchored dead center and although there is so much going on in this track musically, the Status 8T’s were easily able to resolve every detail with more conviction than I’ve heard from any other speaker system. The Status 8T system really shows off the fabulous acoustical guitar work of Track #5 “Why Worry”. I was in such a lucid state that I must confess I didn’t remain fully conscious though the end of the song. Instead I just floated along basking in an audiophile psychosis. Track #6 “Ride Across the River” woke me up placing me in the middle of the Serengeti Jungle. The realism had me convinced I needed to apply a healthy dose of insect repellent to avoid getting bit. Well, maybe I’m exaggerating just a bit, but the experience was pretty mind numbing. The bass was snappy and tight while the electric guitar just punched into my cranium. I honestly didn’t realize this song has so much depth and detail in the bass department until I heard it on the 8T speaker system.

CD:

Michael Franks - Burchfield

Nines

I wanted to hear the delicate side of the Status 8T system so I broke out some classic Michael Franks music. Track #1 “When the Cookie Jar is Empty” Michael's voice had no hint of chestiness or containment. Instead he was just there singing to me just like a live unamplified performance with the electrical guitar panned to the left speaker. Steve Gadd’s bass drum sounded nice and damped as if he removed the back head and stuffed it to give that nice thump sound. Track #2 “A Robin Song” showcased how neutrally the Status 8T system could convey vocals. There was such an immediacy and richness to the vocals and brass instruments that I’ve never heard in any other speaker system regardless of price. The saxophone seemed to just implant itself into the left side of my head. The cymbal reproduction of Track #3 “Wrestle a Live Nude Girl” was immensely transparent. Again I was loving the thump of Steve Gadd’s bass drum and basking in sonic nirvana while pondering how cool the title of this song was….not as cool as the actual song I can assure you. A bit obscure perhaps, but this music is timeless. Track #4 “Burchfield Nines” is a slow kinda downbeat song but patience rewards with a beautiful melody and some great instrumentation. You’re showered with triangles that just slowly dissolve into the room along with clanking percussion sounds reproduced with pristine clarity from the wonderful beryllium tweeters. The trumpet just radiated outwards with a sense of realism and warmth difficult to adequately convey in words. This is just something you’d have to hear to appreciate.

I listened to this CD with my wife present and asked her to put her thoughts in writing as follows:

“The xylophones and triangles chimed swiftly with emanating voices that were very natural and organic. Excellent clean vocals and reverb gave the ‘air’ of sensuality, but calm finesse. Bass was tight and pleasant to the ears with a very realistic and live feeling as if the artist was romancing you with their vocals and instruments. Differentiation between the instrumentation was easily heard without losing its smoothness. Wind instrumentation had a particular nice reverb, and was very smooth and dispersing swiftly around you, never sounding fatiguing even at louder listening levels.”

Blu-ray: Animusic HD, Tron Legacy, & Avengers

Blu-ray: Animusic HD, Tron Legacy, Avengers

While the focus of this review is for two-channel applications, I thought it would be good measure to briefly discuss how the Status 8T system also handled home theater as well. I cued up two bass intense movies and one music blu-ray running the 8Ts as full-range with the sub/LFE routed directly to the speakers. No additional powered subwoofers were used to supplement the bass.

Animusic HD is a great demo disc chock full of great music choreographed to clever computer animation. As an avid ELP fan, “Cathedral Pictures” is a particular favorite of mine. Listening to full-scale pipe organ music blasting throughout the room was simply sensational. This type of recording is murder for a tweeter but the beryllium drivers handled it with ease and finesses free from any artifacts or graininess. I heard phenomenal surround envelope between the Status 8T towers and my RBH 66-SE/R and SI-640/R surround speakers. Panning between the front three speakers was very uniform as the Status 8C center channel was providing a very good timbre match to the 8T towers. Expect a dedicated review of the 8C center channel to follow.

Tron Legacy was a smorgasbord of visual and sonic delights. The deep tactile bass during the fight scenes had me pinned to my seat just basking in bassaholic euphoria. These scenes captivated me in a way that was surreal, feeling as if I was in a high powered futuristic nightclub minus the cheesy men soliciting women for a dance, or the smell of bad liquor mixed with cigarette smoke and body sweat. I honestly couldn’t believe how well extended and full the bass was all around my room without using any active subwoofers or EQ’ing.

I felt as if I were caught in the middle of the battleground of the opening scene of Avengers when Loki stole back the Tesseract causing the secret S.H.I.E.L.D. installation to implode. The Status 8T system was proving to me it was equally at home handling critical two-channel or multi-channel applications.

Defining a Reference Loudspeaker

I

normally wouldn’t take up review real estate like this, but in the rare

occasion when a product comes to me for review that raises the bar of

performance in our listening labs, I feel special notice must be given within

the confines of the review itself. The

Status Acoustics 8T system is such a product.

This loudspeaker system has truly revolutionized what high-end audio

means to me. For years, I’ve let

two-channel audio take a back seat to multi-channel. But, since I’ve had the

chance to sit down and listen to these speakers that has completely changed for

me. I find myself wanting to get back to

the basics again and for the first time in over 20 years, I’m also spinning

vinyl records. What’s even more at odds

is the fact my wife has also taken notice.

She was just loving sitting with me listening to two-channel audio

whereas in the past the only time I could get her to really sit down and enjoy

high fidelity was if we were watching a Blu-ray concert disc or movie. Now she is out scouring Amazon for deals on

used and new records.

I

normally wouldn’t take up review real estate like this, but in the rare

occasion when a product comes to me for review that raises the bar of

performance in our listening labs, I feel special notice must be given within

the confines of the review itself. The

Status Acoustics 8T system is such a product.

This loudspeaker system has truly revolutionized what high-end audio

means to me. For years, I’ve let

two-channel audio take a back seat to multi-channel. But, since I’ve had the

chance to sit down and listen to these speakers that has completely changed for

me. I find myself wanting to get back to

the basics again and for the first time in over 20 years, I’m also spinning

vinyl records. What’s even more at odds

is the fact my wife has also taken notice.

She was just loving sitting with me listening to two-channel audio

whereas in the past the only time I could get her to really sit down and enjoy

high fidelity was if we were watching a Blu-ray concert disc or movie. Now she is out scouring Amazon for deals on

used and new records.

People often ask me what a true reference speaker should sound like. My answer has always followed with something that sounds as close to a live unamplified performance as possible. This is much different than what most consider as reference, since so few people have actually had the luxury of hearing a phenomenal acoustical performance not destroyed by mediocre sound reinforcement systems (whose sole goal seems to be boosting the SPL to ear bleeding levels in a large concert arena). Growing up in a family of jazz guitarists and musicians has afforded me such a privilege. Hearing a grand piano playing in a lively room or real acoustical drums not mixed through a compressor is an invigorating experience that often gets lost once it’s compressed to the nth degree onto a recording and then further compressed by a loudspeaker system not capable of recreating the full dynamics.

I don’t define a loudspeaker reference product by its ability to measure a flat frequency response from 20Hz to 20kHz. Most speakers never really measure that way unless the measurements are massaged to appear so, and if they did, they would actually be unpleasant to listen too. I didn’t conduct any measurements of the Status 8T system until I was completely finished with my listening tests. I didn’t want graphs to influence my subjective impressions with this product. What I’ve found though nearly three months of constant listening to these speakers was that they set a true reference, NOT just as far as flagship tower loudspeakers are concerned but for ALL loudspeakers of any category in general.

Over the past six years I’ve been happily living with the $15k/pair RBH Sound T-30LSE system. This system combines tremendous output and a huge soundstage for lifelike dynamics which until I received the Status 8T system for review was unrivaled in my listening space. The Status Titus 8T system was designed not only to outperform the T30-LSE system in terms of sheer output, but also to eke out even more detail and fidelity. Until I was able to hear this for myself, I was skeptical just how much further the fine engineering talents from RBH Sound would be able to push the performance envelope.

Status 8T Tower Speaker Installed in Audioholics Showcase Theater Room

From mids to highs, I’d say both systems had a very similar ability to effortlessly produce clean fidelity and dynamics, but the Status 8T system just did so with more intimacy and immediacy in the soundstage. The sound seemed more precise and focused on the 8T system while it also seemed more uniform off-axis thanks to the fact that the 8T system employed a single tweeter over the multi-tweeter design of the T30-LSE system. It was truly impressive to hear a single tweeter design able to take the punishment I gave it and it made me realize just how special and worthy this $500 beryllium tweeter really is.

From a bass standpoint, the 8T system trounces the T30-LSE’s. The Status 8T system not only has a lot more bass output capability thanks to the extra 10” bass driver and more port area, but it also has the advantage of radiating bass from several surfaces of the cabinet. This increases modal density loading in the room and allows for a much more linear and smoother bass response across the entire listening area. With my T30-LSE system I always felt the back row had a bit of a boomy sound to it , which I could only smooth out with active equalization. The Status 8T system needed no EQ at all and the additional subs I had were kept only for multi-channel usage, but even they weren’t really needed. I had plenty of extension and output from just the Status 8T bass modules and they sounded great on their own no matter where I sat in the room. Quite frankly, this was a real shocker for me. I was able to run the Status 8T system as a full-range tower for my theater rig, routing all bass and LFE to them, achieving theatrical levels of bass for truly satisfying movie watching and concert listening experiences. I’ve never been able to do this with another loudspeaker system before because all others either lacked the depth and output capability or they were unable to produce such consistently good bass for every seat in my room.

Another aspect of performance that boggled my mind with the Status 8T system was the fact that I experienced no appreciable tonal shifts from seated to standing position or moving my head from left to right at my primary seating area. Because of the asymmetry of my room I’ve often wrestled with this problem with virtually all speakers I’ve had in for review (especially multi tweeter designs like the T30-LSE’s), but the Status 8T system simply didn’t accentuate this issue. I later realized that it perhaps had something to do with the fact that the very top and bottom midrange drivers of the 8T system were virtually equidistant from the ceiling and floor surfaces, respectively. Perhaps this helped produce consistent ceiling and floor reflections. Also this speaker allows a much higher proportion of direct sound to reach the listening area helping to mask room acoustical anomalies. It was obvious to me that the Status 8T system was well suited for my listening space.

Status Acoustics Titus 8T Floorstanding Speaker System Measurements and Analysis

Measuring the Status 8T Outdoors @ 2 meters

Measurements were conducted both outdoors and indoors using the LMS system from Linear X for frequency response and impedance measurements and the OmniMic system from Dayton Audio for distortion measurements.

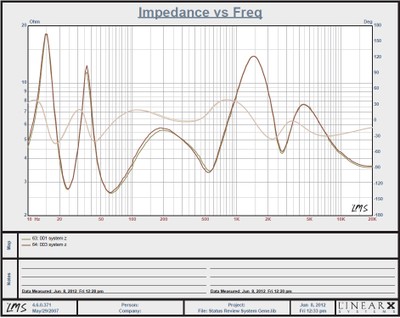

Impedance / Phase Measurements of the Status Acoustics 8T Speaker System

Separated

Impedance of the Status Acoustics 8T Speaker System

Purple

trace: bass module ; Blue trace: Satellite module

The first impedance/phase sweep was taken on each Status 8T system configured with the satellite and bass module wired together for single amplification mode while the second measurement graph separated the impedance of the bass and satellite modules. Thanks to tight tolerances in parts and consistency in cabinet stuffing, both speakers measured nearly identical throughout the entire audio bandwidth. I’ve never seen a pair of speakers track this closely, especially ones with multi drive units like this system.

The Status Acoustics 8T speakers appear to be tuned at around 22Hz, but the peaks are slightly asymmetric indicating the system is tuned a bit higher than the driver's resonance frequency. This allows for more power handling down to 20Hz region. Because of the multi-driver array paralleling essentially three 8 ohm bass drive units, the Status 8T system can be a strenuous load for an amplifier, dipping down below 3 ohms in the lower bass regions. I was puzzled why Status Acoustics didn’t employ 12 ohm drivers to keep the system impedance above 4-ohms so I asked Shane Rich.

Editorial Note about the Low Impedance of the Status 8T System by Shane Rich:

1. Let me answer the question with a question. Why would anyone design a 4 Ohm speaker vs. an 8 Ohm speaker? The same logic applies to your question. Again, this is assuming we are using amplifiers that are capable of putting out the current necessary to extend the dynamics of the system at lower impedance loads. Case in point, the voltage rails of my ADA amp are about the same as the Boulder amplifier we have used. Why then does the Boulder sound so much more dynamic?

Answer: It is delivering more power into the load the speaker presents to the amplifier. Yes the efficiency of the amp may be reduced somewhat, but if the amp can output 600W into a 4 Ohm load and still put out 1200W into a 2 Ohm load, why not utilize the available power?

2. There would be a reduction of sensitivity of the system in the bass frequencies if all else were equal. The voltage sensitivity of the system would be reduced by a dB or 2 in the bass frequencies so in effect the balance of the sound would change and speaker would have a "lighter" less bassy bottom end.

That being said, yes, I will admit to briefly considering the option of using a 12 Ohm coil like I did in the in the three paralleled 8" drivers utilized in the RBH 8300 towers, but I ruled that out after seeing how well balanced system was using the existing 10" drivers and knowing the buyer for these speakers was likely to use a monster amp to power them.

Though the phase varies substantially at low frequencies (10Hz to 20Hz), the swings aren’t of much consequence given the magnitude of the impedance. Notice that the magnitude of the impedance never drops below 5 ohms at the phase angle extremes in the bottom end. Magnitude is 6-ohms at 18Hz where the phase angle is -42 deg and 5.2 ohms at 42Hz where the phase angle is -39 deg. Any good quality high power 4 ohm capable amplifier should be able to drive this speaker without too much difficulty, but again I recommend pairing them with the best amplification you can get your hands on. Of course in bi-amp mode, the end user should select amplifiers with similar gain structures but with an emphasis on the amp powering the bass modules being stable down to 2 ohm loads. The satellite module is a relatively easy load for any good quality 4 ohm rated amplifier to drive.

Status Acoustics specifies system sensitivity at 93dB at 2.83V/meter. I measured about 92dB with a slight bump in the bass so their claim seems to be pretty accurate.

Status Acoustics 8T In-Room 1.75 Meter Listening Window Response (1/12th octave smoothed)

Measuring a speaker like the Status 8T is a difficult task not only because of the complex multi-driver array, but also its sheer size making it hard to move around or measure outdoors. Having multiple front firing bass drivers and rear ports makes this task even trickier. With that I took a combination of five measurements (on-axis, +/-15 deg off axis vertically and 15 and 30 deg off axis horizontally) and averaged them to form a listening window response curve. I then took the outdoor groundplane measurement we made on the bass module and spliced its response to the listening window response at 150Hz. Overall this gives a fairly accurate representation of what the speaker would look like quasi-anechoic at 2 meters. As you can see the response is extremely linear above the splice point maintaining a +/- 2.5dB frequency response out to 20kHz and that’s with measurements 30 degrees off-axis averaged into the overall response curve. The slight dip in the 100Hz to 200Hz frequency is a measurement artifact of measuring this speaker at such a close distance caused by the interference of the first reflection off the ground.

There is a bit of a bump (2-3dB) in the 30-60Hz region which is probably responsible for the 8T systems very tactile response that adds a pleasant warmth to the sound. It’s interesting to note that the groundplane sweeps we ran on the bass module produced the same response curve below 150Hz with no compression out to 115dB where the amplifier we used ran out of power. The 8T bass module didn’t break a sweat and was ready for a kilowatt amp, which sadly we didn’t have on-hand during the time these measurements were conducted.

Status

Acoustics 8T Outdoor 2 Meter Off-Axis Response (1/12th octave

smoothed)

Blue:

on-axis; Purple: 15 deg; Green: 30 deg; Yellow: 45 deg

Taking a closer look at the off-axis response of the Status 8T system really gives a true appreciation of the caliber of performance the Scan Speak 6640 Beryllium offers. Just look at how smooth the upper frequency response is on-axis and how gradual the roll-off is all the way out to 45 degrees off-axis. You very rarely see a tweeter with such a smooth, predictable rolloff from 0 to 15 to 30 to 45 degrees off-axis. Usually there's some resonance somewhere so one of the off-axis curves actually spikes above one of the other curves somewhere in the band. That’s clearly not happening here. Also, the 0 and 15 degree curves are almost identical, indicating the tweeter has superbly good dispersion and the dome is obviously not mounted in a recess that restricts its off-axis output. This indicates excellent performance and a well integrated system. The lack of measurement artifacts also indicates a very well engineered front baffle.

Status

Acoustics 8T In-Room 1.75 meter Frequency Response Comparison (1/12th

Octave Resolution)

Purple:

no grille; blue: with grille

Of course it’s always recommended to listen to your speakers with the grilles off, especially these babies, but it’s also good to know that a properly engineered grille can not only provide protection for the drivers but do minimal harm to the sound. The Status 8T grilles are pretty transparent, as indicated in the measurement above, but they aren’t perfect. You can see some loss in the critical 2 kHz midrange and upper 8-10kHz areas. This may be a result of the ½” standoffs not allowing them to flush mount against the baffle. Making these grilles magnetic looks great so it’s a small sacrifice to pay in performance and anyone serious about audio will not be using these grilles during critical listening sessions anyways.

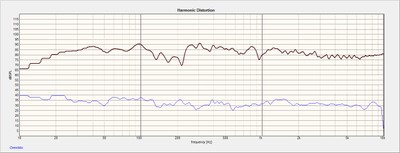

Status Acoustics 8T In-Room THD Distortion Measurement (@ listening position)

Using the OmniMic system, I positioned the mic 1.5 meters away from the 8T’s tweeter to do a frequency vs. distortion sweep. This is a similar test to how the NRC does distortion. In my opinion this type of distortion test doesn’t give you the whole picture but it does wring out obvious flaws or problems with the speaker system. I drove the 8T’s at high output (more than my ears could take for any duration of time) and I noticed as I increased the volume, the output level went up but the distortion curve did not. This indicated to me that the Status 8T system distortion was below the noise floor of my room. So, I repositioned the mic to the listening area almost 14ft away from the speakers and ran a full-range sweep from 10Hz to 20kHz with both speakers driven. Again, the same excellent results were produced. This was the cleanest system I’ve ever measured. Most speaker systems distortion goes way up at low frequencies since hardly any so called “full-range” towers are really full-range. This was not the case with the 8T system as you can see in the graph above. This is what happens when you mate multiple high quality drivers in a large box with well-executed crossover design.

It’s also particularly interesting that the frequency response with both speakers driven at the listening position was +- 5dB from 20Hz to 10kHz and this graph retained 1/12th octave resolution. Thanks to the higher proportion of direct sound to the listening area, the response at the primary listening seats is very linear. This is unachievable in my room with conventional 2-way or 3-way designs without the use of electronic room correction.

If you want to convert the THD to physical numbers, you can subtract the SPL sweep (black) from the distortion sweep (blue) at corresponding frequencies and convert the numerical # to a percentage as follows:

| dB Below Test Tone | % Distortion |

| -5 dB | 56.2% |

| -10 dB | 31.6% |

| -15 dB | 17.8% |

| -20 dB | 10.0% |

| -25 dB | 5.62% |

| -30 dB | 3.16% |

| -35 dB | 1.78% |

| -40 dB | 1.00% |

| -45 dB | .562% |

| -50 dB | .316% |

| -55 dB | .178% |

| -60 dB | .100% |

| -65 dB | .056% |

| -70 dB | .032% |

| -75 dB | .018% |

| -80 dB | .01% |

Distortion Table (dB to % Conversion)

For example at 1kHz, the 8T SPL was roughly 95dB (at 1 meter) while the THD level was 35dB. 95dB – 35dB = 60dB or 0.100% THD.

The Downside

Really the only downside I can think of regarding the Status 8T speaker system is size and cost. These speakers are very large and heavy. Installing a pair of 8T’s in a listening room is not a one man job and a product of this caliber should be installed by a professional. At $50k/pair, these speakers don’t come cheap - but audiophiles shopping speakers in this price class probably aren’t too concerned about that. Because this speaker system is so revealing, I have found that the quality of upstream components attached to them really makes a world of difference. Hearing a proper setup of this system may spoil your sonic palate making it hard to settle for anything less. Be warned!

Status Acoustics does offer the matching 8C center channel and will soon be releasing a bookshelf speaker to complete a full multi-channel surround solution, but they currently have no dedicated powered subwoofer. I would really like to see Status Acoustics offer a powered sub based on the bass module for this product. I could only imagine how such a sub with a meaty amp and trick DSP circuit would produce benchmark performance measurements and sound in the cost-no-object powered subwoofer category. Of course a diehard Audioholic with the bankroll of Warren Buffet or Bill Gates would just use five 8T speakers and call it a day J

Recommendations

Investing

in a pair of speakers of this stature requires great effort in setting them up

in the proper listening space with equipment capable of allowing them to reach

their full potential. These speakers

need a lot of breathing room to strut their stuff. I’d recommend a room large enough that will

allow you to place them 3-4ft away from the back wall while being able to place

the primary seating area a good 10-12ft from the speakers. Perhaps a room size of 20ft x 15ft would be a

good minimum recommendation.

of this stature requires great effort in setting them up

in the proper listening space with equipment capable of allowing them to reach

their full potential. These speakers

need a lot of breathing room to strut their stuff. I’d recommend a room large enough that will

allow you to place them 3-4ft away from the back wall while being able to place

the primary seating area a good 10-12ft from the speakers. Perhaps a room size of 20ft x 15ft would be a

good minimum recommendation.

I recommend caution when pairing the Status 8T system with a Class D amplifier. I experienced non-optimal sonic results when mating them with this type of amplifier I had on hand. It simply didn’t handle the low frequency impedance swings with as much grace or finesses as the very best linear amplifiers I paired them up with. In order to achieve the full potential this speaker system has to offer, it’s recommended that you select an amplifier that is as close to an ideal voltage source as possible, doubling down in power as impedance halves (ie. 300wpc at 8-ohms, 600wpc at 4ohms, 1200wpc at 2ohms). It’s a good idea to verify with the amplifier manufacturer of your choice if their product is truly stable down to 2-ohm loads. Using an amp not capable of sourcing lots of current into 4- and even 2-ohm loads will result in clearly audible inferior results especially at louder listening levels with bass intense program material. I had excellent results pairing these speakers with amplifiers from Classe and Pass Labs and I am confident you would too but also check out options from ATI, Anthem, Boulder, and Bryston to name a few.

Status Acoustics Titus 8T Floorstanding Speaker System Conclusion

Spending

the last three months with the Status Titus 8T speaker system has been a true

audiophile revelation for me. This

speaker has transformed the way I listen to music as I seem to now place more

emphasis on two-channel over multi-channel listening these days. Even after all this time listening, the

honeymoon phase has still yet to wear off.

I am still in awe each time I engage in a listening session, denying

that the fidelity could be as good as I remembered the day before. There are times that I like to just sit and

stare at the beauty of this design because it’s truly a unique-looking

loudspeaker. In fact, the Status 8T

system is quite a conversation piece as they make their presence known to

anyone who comes into my theater room for a visit. People are instantly drawn to these speakers,

like Pavlov’s dog to a steak, wanting me to fire them up for a listen. They sound great just looking at them!

Spending

the last three months with the Status Titus 8T speaker system has been a true

audiophile revelation for me. This

speaker has transformed the way I listen to music as I seem to now place more

emphasis on two-channel over multi-channel listening these days. Even after all this time listening, the

honeymoon phase has still yet to wear off.

I am still in awe each time I engage in a listening session, denying

that the fidelity could be as good as I remembered the day before. There are times that I like to just sit and

stare at the beauty of this design because it’s truly a unique-looking

loudspeaker. In fact, the Status 8T

system is quite a conversation piece as they make their presence known to

anyone who comes into my theater room for a visit. People are instantly drawn to these speakers,

like Pavlov’s dog to a steak, wanting me to fire them up for a listen. They sound great just looking at them!

The Status 8T system has an uncanny ability of sounding larger than life yet focused like a laser. Their sound transcends their physical cabinets, which is grandiose and in your face when called to do so, yet delicate like the petals of a rose beckoning you to carefully listen, rewarding you with pure unadulterated audio perfection. The 8T speaker system has a fundamental rightness to its sound that just hooks you into spending more time listening. In fact, the biggest issue I’ve found with these speakers is once you engage in a listening session either solo or with friends, time seems to speed up. Einstein would be puzzled by the reverse time-dilation paradox these speakers often create with unwary listeners. I’ve noticed my wife and I have been plowing through bottles of wine with greater frequently since I’ve gotten these in for review.

If you’re in the market to assemble a cost-no-object audiophile two-channel or multi-channel system, I can’t imagine anyone not being completely satisfied with the new Status Acoustics Titus 8T speaker system. These are truly what I consider to be “speakers for life” in that once you own a set, there’s pretty much no need to upgrade in the future.… unless, of course, the folks at Status Acoustics come up with something even more impressive. Highly recommended if you’ve got the coin and space!

Many thanks to Steve Feinstein for his technical contributions and peer review

Status Acoustics Titus 8T Floorstanding Speaker System

MSRP: $50k/pair

Status Acoustics

Mailing Address:

382 Marshall Way

Layton, Utah USA 84041-7318

Phone and Fax:

Toll-free: (800) 543-2205

Phone: (801) 543-2200

Fax: (801) 543-3300

Email Address:

sales@statusacoustics.com

The Score Card

The scoring below is based on each piece of equipment doing the duty it is designed for. The numbers are weighed heavily with respect to the individual cost of each unit, thus giving a rating roughly equal to:

Performance × Price Factor/Value = Rating

Audioholics.com note: The ratings indicated below are based on subjective listening and objective testing of the product in question. The rating scale is based on performance/value ratio. If you notice better performing products in future reviews that have lower numbers in certain areas, be aware that the value factor is most likely the culprit. Other Audioholics reviewers may rate products solely based on performance, and each reviewer has his/her own system for ratings.

Audioholics Rating Scale

— Excellent

— Excellent

— Very Good

— Very Good

— Good

— Good

— Fair

— Fair

— Poor

— Poor

| Metric | Rating |

|---|---|

| Build Quality | |

| Appearance | |

| Treble Extension | |

| Treble Smoothness | |

| Midrange Accuracy | |

| Bass Extension | |

| Bass Accuracy | |

| Dynamic Range | |

| Performance | |

| Value |