JL Audio E-Sub e110 and e112 Subwoofers Review

- Product Name: E-Sub e110 and e112 Subwoofers

- Manufacturer: JL Audio

- Performance Rating:

- Value Rating:

- Review Date: May 05, 2014 08:30

- MSRP: $ 1,500 e110 Black Ash ($1,700 Gloss Black) / e112: $1,900 Black Ash ($2,100 Gloss Black)

JL Audio E Series Specifications

10” (e110) or 12” (e112) JL Audio proprietary long throw woofer

¾” MDF cabinet, internally braced

Steel driver mounting flange forms the front of the enclosure

Amplifier: 1200 watts short term (e110) / 1500 watts short term (e112)

Frequency Response (Anechoic): 25-116Hz +/-1.5dB (e110) / 22-118Hz +/-1.5dB (e112)

Finishes: (Standard:) Black Ash, (Optional) Piano Gloss Black ($200 Extra)

Dimensions (H/W/D): 13.5” x 14.24” x 16.51” (e110) / 15.5”x16.23”x18.39” (e112)

Weight: 53lbs (e110) / 73lbs (e112)

Warranty: 3 years (bumper to bumper)

JL Audio E Series Driver Features

Integrated steel mounting flange

Proprietary cast aluminum frame

Patented vented reinforcement collar (VRC)

DMA optimized motor with double stacked ceramic magnets

Threaded back plate bolts into enclosure for support

Large rubber, half roll surround

Twin large diameter spiders with differing diameters and extreme spacing

Engineered lead wires (ELWS)

Designed and assembled in the U.S.A.

JL Audio E Series Amplifier Features

High efficiency, regulated, switching design with low latency analog signal processing

Detachable power cord

Top panel controls with cosmetic cover

Speaker level inputs

Stereo Unbalanced RCA inputs and outputs

Power toggle Auto, On or Off

Gain control

Variable Linkwitz-Riley 4th order low pass filter, 25-130Hz with bypass switch

Phase control 0-180deg variable

Polarity switch

Ground lift

Pros

- Excellent construction and finishing

- Very high quality components

- Ultra compact yet powerful

Cons

- Multiples may be required to fill larger spaces

JL

Audi o is a brand likely to be familiar to anyone who has been into either

mobile or home audio for any length of time. With roots stretching back into

the late 70’s, JL Audio or “JL” for short, has established itself over the

years as one of the most recognizable brands in mobile audio and about 8 years

ago made quite a splash with their formidable Fathom line of powered subwoofers.

Indeed much of the JL Audio reputation was built through the performance and

sound of the subwoofers and amplifiers that they produce and I suspect this is still

their bread and butter. In fact JL holds a number of patents related to audio

and bass driver design and utilize a proprietary DMA finite element analysis

(FEA) based system developed in house that is used in conjunction with other sophisticated

modern technologies such as a Klippel analyzer during product design and

development. JL still designs and builds the majority of their top lines right

here in the good ole United States too. JL Audio has been flexing these

resources for quite a while to develop a new line of powered subwoofers aimed

at the home and studio market and recently released the “E” series of powered

subwoofers consisting of the e110 ($1,500 in black ash and $1,700 in gloss black)

and the e112 model ($1,900 in black ash and $2,100 in gloss black). This E

series are in many ways similar to the earlier Fathom series as both lines are

compact sealed systems utilizing a single forward firing driver and a powerful

amplifier, but the E series are targeted at a lower price bracket and are in

other ways quite different. JL Audio graciously offered to send both an e112

and an e110 for review. Finding myself with the chance to spend some quality time

with not one but both of the new E series subwoofers I jumped at the chance, so

this will be a special double review of both the e110 and the e112.

o is a brand likely to be familiar to anyone who has been into either

mobile or home audio for any length of time. With roots stretching back into

the late 70’s, JL Audio or “JL” for short, has established itself over the

years as one of the most recognizable brands in mobile audio and about 8 years

ago made quite a splash with their formidable Fathom line of powered subwoofers.

Indeed much of the JL Audio reputation was built through the performance and

sound of the subwoofers and amplifiers that they produce and I suspect this is still

their bread and butter. In fact JL holds a number of patents related to audio

and bass driver design and utilize a proprietary DMA finite element analysis

(FEA) based system developed in house that is used in conjunction with other sophisticated

modern technologies such as a Klippel analyzer during product design and

development. JL still designs and builds the majority of their top lines right

here in the good ole United States too. JL Audio has been flexing these

resources for quite a while to develop a new line of powered subwoofers aimed

at the home and studio market and recently released the “E” series of powered

subwoofers consisting of the e110 ($1,500 in black ash and $1,700 in gloss black)

and the e112 model ($1,900 in black ash and $2,100 in gloss black). This E

series are in many ways similar to the earlier Fathom series as both lines are

compact sealed systems utilizing a single forward firing driver and a powerful

amplifier, but the E series are targeted at a lower price bracket and are in

other ways quite different. JL Audio graciously offered to send both an e112

and an e110 for review. Finding myself with the chance to spend some quality time

with not one but both of the new E series subwoofers I jumped at the chance, so

this will be a special double review of both the e110 and the e112.

The E series subs both arrived at the same time and are not overwhelmingly large but the e112 in particular still had significant mass to it in the box. Cutting open the boxes revealed that the packaging is the same for both units, a single heavy gauge cardboard carton with a 2-piece Styrofoam insert to protect the subwoofer. Each subwoofer is inside of a cloth bag which is inside of a plastic bag to protect the finish. The accessories list is short and sweet with just the owner’s manual, which is quite well written and thorough and the detachable power cord. Unpacked and sitting on the floor the very small size of the E series subs becomes apparent. While the e112 is quite trim, or what I would classify as a miniature subwoofer, the e110 is downright diminutive and is what I like to call a micro sub. The e110 is physically one of the smallest subwoofers I have ever reviewed. Despite the small stature these subwoofers are built very sturdily and have significant mass that belies their size. The e110 is listed at just less than 53lbs, while the slightly larger e112 tips the scales at a hair under 74lbs. These are no featherweights, but neither the e110, nor the e112 should pose a handling problem for a single adult in good health. Both the e110 and e112 review units arrived in the more expensive gloss black trim, which I found well applied, deep and which easily reflected back clear images in the right light. In retrospect I should have asked for one of the review units to be in the base black ash finish so I could compare both finishes. Oh well…The amplifier controls are located on the top of the amplifier on the back of the E series instead of on the back plate of the amplifier as is seen with most units, which is a much more convenient place to reach in most instances. A cover panel for the controls is also supplied to prevent inadvertent adjustments, which appears to be molded out of a rubber material. The amplifier controls are a brushed aluminum finish when the cover is removed, which provides a nice accent to the look. The grilles are nothing flashy but feel solid and snap into place soundly. Removing the grilles shows the drivers to be adorned by only a very small logo and due to the mounting system employed in the E series, no driver mounting screws are visible other than 4 large screws which anchor the steel front baffle to the rest of the enclosure. The E series have clean lines, are well finished and are certainly attractive as far as subwoofers go.

JL Audio e112 Subwoofer Youtube Review

Design Overview

The E series subs as previously mentioned are very small sealed designs with a single forward-firing driver and a powerful on board amplifier. The e110 is so named because it houses a single 10” driver and the e112 houses…You guessed it…a 12” driver. The amplifier for the e110 is rated at a robust 1200w and the e112’s amplifier carries an even more powerful 1500w rating. There are 2 finishes available, both of which are black. The standard finish is a black ash which shows some wood grain and is less reflective. The second is the high gloss black which both the e110 and e112 review units came dressed in and which carries a $200 upcharge over the basic black ash finish. Typically I am the type of guy who would pocket the extra cash rather than splurging extra just for a cosmetic enhancement, but I have to admit the E series subs really wore the gloss black well and I’m not sure if the standard ash finish would have been as visually arresting.

Since the driver of the E series subs is a bit unique and there was mention of the motor bolting into the cabinet in the literature, I decided it might be best to inquire with JL Audio about how to remove the driver and amplifier before attempting to do so. After briefly speaking with Brett about it, JL’s lead engineer on the E series project, I was informed that there really isn’t much to it. I figure it’s better to be safe than sorry with a loaner $2,100 subwoofer though. Armed with the knowledge of how to go about disassembly of an E series sub it took all of 5 minutes.

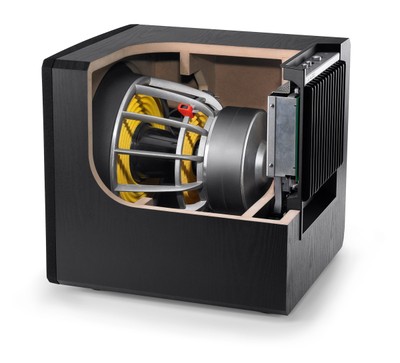

It is often said that the driver is really the heart of a subwoofer and in the case of the JL Audio E series that may be an even more apt description than normal. These are no ordinary drivers. The design of them at some point veered off the traditional track and ventured out into previously unexplored territory. JL has not been shy about sharing pictures and information about the drivers developed for the E series and one look at them indicates that these are a little bit unconventional. To begin with they are abnormally deep units with the overall depth equaling or exceeding the diameter. Part of the reason for this is the result of an effort by JL’s engineers to increase the suspension linearity and resistance to the former rocking at high excursions by spacing out the suspension elements more than usual. The surround is in its normal position at the cone edge and there is a large diameter spider in its traditional position near the motor and voice coil. Typically the cone would also meet the former and spider at this point forming the triple joint. The E series drivers greatly stretch out and increase the depth of the former and frame and add a second spider landing between the surround and traditional spider placement up close to where the cone now meets the former. The result is a very deep driver that looks a bit odd with a very deep, open designed 12-spoke, cast-aluminum frame and spiders of different diameters spaced a good 3-4” apart. This design should be very stable and resistant to rocking effects at high excursion. In between and linking the 2 spiders and the former is a black plastic piece that I assume uses JL’s VRC technology to firmly lock the former and both spiders together into a single moving unit. Another interesting feature of the drivers is that the typical mounting flange is gone and there is a large, square, steel flange attached to the front of the driver that mounts into the enclosure and actually composes the front of the finished subwoofer. It comes up around the surround enclosing the area between the top spider landing and surround and also recesses the driver. I’m not sure of the exact reasoning behind this piece but it is certainly different. On a more traditional front the cone is concave and shares a family resemblance to the W7 or Fathom drivers. It is adorned with only a small JL logo at the bottom of the cone. The surround is rubber material formed in a half roll that supports large excursions. The motor itself also appears rather conventional compared to the rest of the driver with a stacked pair of large diameter ferrite magnets, a deeply bumped back plate and a top plate of what looks to be about 12mm in thickness. The back plate is also threaded so that it may be bolted into the enclosure. With drivers this deep the heavy motor can apply a significant amount of leverage to the mounting baffle and frame since it is hanging back so much further than usual, so supporting the motor is an extra bit of precaution in case the subwoofer is dropped or otherwise encounters a high G loading on the motor. The voice coil of the E series drivers is a 2” diameter affair that appears to be 4 layers of substantial winding length for extended Xmax. The owner’s manual mentions that the e110 driver is capable of 2.5” peak to peak excursions and that the e112 driver is capable of 3” peak to peak excursions. After watching the driver movements during a few loud action movies and conducting CEA-2010 burst testing on the E subs outdoors I’m inclined to believe them. These are very high quality drivers and it is obvious that a lot of resources and effort were used in the development of them and that they were engineered specifically for the E series application.

JL Audio E series Driver

The amplifiers employed in the e110 and e112 subwoofers are high efficiency regulated switching designs both rated to produce well in excess of 1kw and like the drivers used in the E series, are specifically tailored to the individual application. These amplifiers have a simple input and output layout with stereo unbalanced inputs and outputs. There is also a set of high level inputs, a ground/lift switch and a fuse by the detachable power cord. All of the usual controls for balancing the subwoofer with the rest of the speaker system are located on the top of the amplifier plate in a recess in the back of the enclosure. These consist of: Gain, 0-180 degree phase control, absolute polarity switch, internal low pass crossover adjustment (24dB/octave Linkwitz-Riley) which also high passes the line outputs and a switch for Auto/On/Off power mode selection. During use the E series amps seemed to have the ability to give the E series drivers all that they could want and despite being run very hard for extended periods at times the amplifiers heat sinks only got slightly warm to the touch.

JL Audio e112 Amplifier

The cabinet of the E series subwoofers are constructed of CNC cut MDF (medium density fiberboard) and contain a couple of large braces internally. The first of which is near the center of the cabinet, which the super-deep drivers pass through and the second of which is back towards the amplifier and which the back of the driver motor bolts to. This second brace is a full wall which seals off the amplifier from the driver. The amplifier occupies most of the back panel while the front panel is almost entirely occupied by the unique steel mounting flange of the driver which bolts into the enclosure face. The front panel is in effect a composite MDF-steel sandwich. With the very short enclosure dimensions, internal bracing and the driver being anchored to the enclosure at both the back and front, these are very dead enclosures. I noticed no panel resonances, rattles or other issues even pushing the subwoofers for all they were worth at the outdoor test site.

The gloss black finish of the E series review units was beautiful and deep. It contrasted well with the aluminum accents on the amplifier and front panel when the grilles were off. The top and bottom edges of the cabinets have a 45 degree angle cut which helps differentiate the profile from that of a plain rectangular body. The amplifier cover piece adorned with the JL Audio logo, fit down into the recessed area for the amplifier controls well and is held in place with magnets molded into it. The grilles were more heavily constructed than most I have encountered and hold in place quite solidly. All of the controls on the amplifier possessed a feel of quality as well. I also enjoyed having the controls on the top of the unit versus on the back of the amp as is typical of most powered subs. It makes adjustment, however rarely needed, just a bit easier. The build quality, fit and finish and ergonomics of the E series subs are all excellent to say the least.

JL Audio E Series Cutaway Cabinet View

JL Audio E-Sub e110 and e112 Subwoofers Sound Quality Tests

Since I had the opportunity to audition both the e110 and e112 subs at the same time I decided to take a slightly different approach and allow the smaller e110 to operate in my tiny computer room paired with a pair of Fostex PM0.4 near-field monitors and being fed primarily music, while the bigger e112 would be given the heavy lifting in the roughly 3300 cubic foot home theater room and primarily fed the LFE channel from movies.

Music listening

Due

to the terrible weather that descended on the Ohio Valley this past winter rendering

the completion of the objective measurements portion of the review impossible,

I actually had the E subs for many months longer than planned and had quite a

bit of time to get acquainted with them and assess their strengths and

weaknesses. Instead of cramming intensive listening into a few weeks I had a

chance to relax with them a bit and allow them to do their thing while I formed

an opinion more slowly with a wider range of material. One of the selections

used to directly audition the e110 was Sting:

Brand New Day, which is a very clean recording I have long used for

critical listening with bass that is unexpectedly powerful and deep in places.

I listened to the entire album and was surprised when the e110 served up clean

helpings of deep bass that I simply expected a sub of its stature to either

skip entirely or muddy up attempting. Impressive…In an effort to see how the e110

would do with the fundamental of punchy rock drums I auditioned many selections

from groups such as Rage Against the Machine, Isis and 12 Foot Ninja. The e110

sounded excellent with all of it and I found that I was able to blend it quite

well with the tiny Fostex monitors, which with their 4” woofers lack any real

bass of their own. The e110 added a whole new dimension to the music by adding

in all of the size and weight that the 4” woofers in the Fostex’s are not

equipped to provide. The e110’s pitch definition was spot on even with complex

bass passages and separation of the percussion from other underlying bass

content was maintained even at what were quite generous playback levels.

Switching gears to a bit more bass-intensive music like Prodigy and NIN I again

was surprised when deep bass effects were reproduced very well. An example

being the NIN track Discipline which has an ascending bass sweep that starts

below 20Hz where again the e110 went above and beyond other similar sized units

I have encountered. In fact quick measurement confirmed that the e110 was solid

until well below 20Hz in this room. Granted my computer room is an easy room to

drive being so small, but I have had a few small subs in that room of varying price

and quality and the others would not perform like this. Typically micro

subwoofers simply lack the extension and power needed to reproduce these types

of effects and often the real deep bass is filtered out and if not, the sub

itself often starts to sound muddled or strained once you put any real volume

to it. The e110 on the other hand was a little terror in this room and would dig

impressively low and also provide quite a punch when called for. Even when I

pushed the volume up to levels that were clearly heard throughout the rest of

the house with Prodigy the e110 remained composed and never seemed flustered.

The fact that it could do a legit 20Hz at a noticeable level was an unexpected

and a pleasant surprise. You simply don’t expect a subwoofer the size of the e110

to pull that off. In all I had the e110 for about 5 months and it got listened

to heavily. I enjoyed it and it never failed to impress me during that time. JL

Audio in fact markets the E series as geared towards near field monitoring or

mixing applications and I even utilized them for a bit of that. Once I got used

to the e110 I could easily monitor with it in the system and make judgments

about how the bass mix and individual tracks were sitting. I could see the E

series performing very well in a mixing type of application.

Due

to the terrible weather that descended on the Ohio Valley this past winter rendering

the completion of the objective measurements portion of the review impossible,

I actually had the E subs for many months longer than planned and had quite a

bit of time to get acquainted with them and assess their strengths and

weaknesses. Instead of cramming intensive listening into a few weeks I had a

chance to relax with them a bit and allow them to do their thing while I formed

an opinion more slowly with a wider range of material. One of the selections

used to directly audition the e110 was Sting:

Brand New Day, which is a very clean recording I have long used for

critical listening with bass that is unexpectedly powerful and deep in places.

I listened to the entire album and was surprised when the e110 served up clean

helpings of deep bass that I simply expected a sub of its stature to either

skip entirely or muddy up attempting. Impressive…In an effort to see how the e110

would do with the fundamental of punchy rock drums I auditioned many selections

from groups such as Rage Against the Machine, Isis and 12 Foot Ninja. The e110

sounded excellent with all of it and I found that I was able to blend it quite

well with the tiny Fostex monitors, which with their 4” woofers lack any real

bass of their own. The e110 added a whole new dimension to the music by adding

in all of the size and weight that the 4” woofers in the Fostex’s are not

equipped to provide. The e110’s pitch definition was spot on even with complex

bass passages and separation of the percussion from other underlying bass

content was maintained even at what were quite generous playback levels.

Switching gears to a bit more bass-intensive music like Prodigy and NIN I again

was surprised when deep bass effects were reproduced very well. An example

being the NIN track Discipline which has an ascending bass sweep that starts

below 20Hz where again the e110 went above and beyond other similar sized units

I have encountered. In fact quick measurement confirmed that the e110 was solid

until well below 20Hz in this room. Granted my computer room is an easy room to

drive being so small, but I have had a few small subs in that room of varying price

and quality and the others would not perform like this. Typically micro

subwoofers simply lack the extension and power needed to reproduce these types

of effects and often the real deep bass is filtered out and if not, the sub

itself often starts to sound muddled or strained once you put any real volume

to it. The e110 on the other hand was a little terror in this room and would dig

impressively low and also provide quite a punch when called for. Even when I

pushed the volume up to levels that were clearly heard throughout the rest of

the house with Prodigy the e110 remained composed and never seemed flustered.

The fact that it could do a legit 20Hz at a noticeable level was an unexpected

and a pleasant surprise. You simply don’t expect a subwoofer the size of the e110

to pull that off. In all I had the e110 for about 5 months and it got listened

to heavily. I enjoyed it and it never failed to impress me during that time. JL

Audio in fact markets the E series as geared towards near field monitoring or

mixing applications and I even utilized them for a bit of that. Once I got used

to the e110 I could easily monitor with it in the system and make judgments

about how the bass mix and individual tracks were sitting. I could see the E

series performing very well in a mixing type of application.

Movie listening session

The e112 definitely got the short end of deal. It was auditioned in my basement theater room which is more than twice the volume of my computer room and much more open. The e112 was also about three times further away from the listening position and it would be asked to reproduce much deeper bass at louder levels from some of the most punishing soundtracks available. No pressure.

As

with the e110, I had such a long time with the e112 that it was used for a

number of casual TV watching nights, movies, Rock Band, you name it. Any time the

main HT system was on the e112 was providing the bass. When listening to more subdued

and casual content such as background music or TV shows the e112 did exactly

what it is supposed to and did not call undue attention to itself and easily

reproduced whatever bass was present in a faithful manner. Let’s be honest with

ourselves here…Most of us don’t buy powerful subwoofers for their low volume

resolving skills. They need to be able

to kick us in the pants when called for. The e112 has this capability. While

viewing concert Blu-rays such as Metallica:

Through the Never or Queen: Rock Montreal with the

volume knob generously cranked up I found that the e112 had real heft in my

room and without starting to sound bloated or overdriven at the levels needed.

One of the best experiences that I had with the e112 was viewing Scott Pilgrim Vs The World. I have enjoyed

this quirky movie and its soundtrack since I first encountered it and the e112

really sank its teeth into this one. Most of the bass in this movie is weird,

punkish, Indy rock music with the drums and bass line mixed way hot and

interspersed with cartoonish, action related slams and thuds. I find it really

fun to listen to. Most of the bass is hottest around the 25-50Hz octave but

there are also occasional forays well below 20Hz with significant level to

them. I thought the e112 did excellently with this movie. I had the master

volume at -10 from what would be referenced level which honestly I thought may

be a bit much for a single 12” driver, but the e112 provided a strong

performance including some large effects during the later fight scenes in the

movie that shook the couch and me. All of the bass in the music throughout the

movie was satisfyingly thumping and the growling distorted bass guitar was

especially nice. Of course I also fed the e112 a couple of demo-worthy scenes

that are known to be really difficult to reproduce and will often cause

problems for many subwoofers. One of these is the plane crash scene from Flight of the Phoenix which is mixed really

loud and contains a mix of frequencies culminating in a very loud 30Hz drone

during the barrel roll of the plane. At a playback level of -10 from what would

be reference the e112 did pretty well with this scene and energized the room

much better than I ever would have expected from a single 12”. I didn’t note

any bad noises or signs of distress from the e112 and it may not have been

quite as powerful of a presentation as I know it can be but for a small, 12”

sub acting all alone, it was one hell of an effort. Another scene I decided to

use for a demo was the bombing of Pearl Harbor from the movie of the same name.

Specifically I look for concussive bass that appropriately conveys the on

screen action and when Cuba Gooding gets on the 50-caliber on deck I listen for

rapid individual pulses of deep bass energy, all of which the e112 once again

punched well above its weight class on. Yet another demo scene that I like to

use to judge just how deeply a subwoofer can effectively extend is in The Hurt

Locker where the 50-caliber is being fired in the desert. The pulses that

accompany each shot during this scene extend very deep in frequency, well below

15Hz in fact and are quite hot. The e112 didn’t quite reproduce all of the bass

on these and it seemed that there was less weight and size to the gun blasts

than I remember, but it also didn’t obviously make bad noises or get itself

into trouble either. Another place where the little e112 again showed its

mettle was the rail-gun test scene from Batman:

The Dark Knight. This one isn’t particularly deep but is very loud and

abrupt bursts of bass. The e112 really slammed hard with these gun blasts once

again producing amounts of sound that really seem out of context to its size.

As a final torture test I usually use the server room scene from the horror

movie Pulse. The movie itself is

almost unwatchable it is so bad, but this particular scene is one of the more

demanding that has been released with loud, sustained, warbling bass centered

at about 17Hz. To top it off there really isn’t a lot of accompanying noise in

the soundtrack either. This scene makes a lot of ported subs, even good ones,

audibly wheeze, some subs skip this sub 20Hz content almost completely and

don’t even try to reproduce it. A lot of other subs cut out and go into protect

or get driven into distress very easily with this content. The e112 didn’t

exactly crumble the building around me with titanic output but it did make a

valiant effort to reproduce the content and did not shut down. This was one of

the few times that I heard distortion from either of the E series subwoofers

but the e112 seemed to be in no actual danger. I did make a point to watch the e112

during some of these demanding tracks and at times the amount of excursion the

driver was producing made it appear as if the cone would jump right out of the

box! These E series drivers are not your average bass drivers that is for sure.

The protection and overload circuitry in the E series must be exceptionally

well dialed in also as even the largest most powerful and expensive subwoofers

I have reviewed thus far have had trouble with some of these demo scenes.

As

with the e110, I had such a long time with the e112 that it was used for a

number of casual TV watching nights, movies, Rock Band, you name it. Any time the

main HT system was on the e112 was providing the bass. When listening to more subdued

and casual content such as background music or TV shows the e112 did exactly

what it is supposed to and did not call undue attention to itself and easily

reproduced whatever bass was present in a faithful manner. Let’s be honest with

ourselves here…Most of us don’t buy powerful subwoofers for their low volume

resolving skills. They need to be able

to kick us in the pants when called for. The e112 has this capability. While

viewing concert Blu-rays such as Metallica:

Through the Never or Queen: Rock Montreal with the

volume knob generously cranked up I found that the e112 had real heft in my

room and without starting to sound bloated or overdriven at the levels needed.

One of the best experiences that I had with the e112 was viewing Scott Pilgrim Vs The World. I have enjoyed

this quirky movie and its soundtrack since I first encountered it and the e112

really sank its teeth into this one. Most of the bass in this movie is weird,

punkish, Indy rock music with the drums and bass line mixed way hot and

interspersed with cartoonish, action related slams and thuds. I find it really

fun to listen to. Most of the bass is hottest around the 25-50Hz octave but

there are also occasional forays well below 20Hz with significant level to

them. I thought the e112 did excellently with this movie. I had the master

volume at -10 from what would be referenced level which honestly I thought may

be a bit much for a single 12” driver, but the e112 provided a strong

performance including some large effects during the later fight scenes in the

movie that shook the couch and me. All of the bass in the music throughout the

movie was satisfyingly thumping and the growling distorted bass guitar was

especially nice. Of course I also fed the e112 a couple of demo-worthy scenes

that are known to be really difficult to reproduce and will often cause

problems for many subwoofers. One of these is the plane crash scene from Flight of the Phoenix which is mixed really

loud and contains a mix of frequencies culminating in a very loud 30Hz drone

during the barrel roll of the plane. At a playback level of -10 from what would

be reference the e112 did pretty well with this scene and energized the room

much better than I ever would have expected from a single 12”. I didn’t note

any bad noises or signs of distress from the e112 and it may not have been

quite as powerful of a presentation as I know it can be but for a small, 12”

sub acting all alone, it was one hell of an effort. Another scene I decided to

use for a demo was the bombing of Pearl Harbor from the movie of the same name.

Specifically I look for concussive bass that appropriately conveys the on

screen action and when Cuba Gooding gets on the 50-caliber on deck I listen for

rapid individual pulses of deep bass energy, all of which the e112 once again

punched well above its weight class on. Yet another demo scene that I like to

use to judge just how deeply a subwoofer can effectively extend is in The Hurt

Locker where the 50-caliber is being fired in the desert. The pulses that

accompany each shot during this scene extend very deep in frequency, well below

15Hz in fact and are quite hot. The e112 didn’t quite reproduce all of the bass

on these and it seemed that there was less weight and size to the gun blasts

than I remember, but it also didn’t obviously make bad noises or get itself

into trouble either. Another place where the little e112 again showed its

mettle was the rail-gun test scene from Batman:

The Dark Knight. This one isn’t particularly deep but is very loud and

abrupt bursts of bass. The e112 really slammed hard with these gun blasts once

again producing amounts of sound that really seem out of context to its size.

As a final torture test I usually use the server room scene from the horror

movie Pulse. The movie itself is

almost unwatchable it is so bad, but this particular scene is one of the more

demanding that has been released with loud, sustained, warbling bass centered

at about 17Hz. To top it off there really isn’t a lot of accompanying noise in

the soundtrack either. This scene makes a lot of ported subs, even good ones,

audibly wheeze, some subs skip this sub 20Hz content almost completely and

don’t even try to reproduce it. A lot of other subs cut out and go into protect

or get driven into distress very easily with this content. The e112 didn’t

exactly crumble the building around me with titanic output but it did make a

valiant effort to reproduce the content and did not shut down. This was one of

the few times that I heard distortion from either of the E series subwoofers

but the e112 seemed to be in no actual danger. I did make a point to watch the e112

during some of these demanding tracks and at times the amount of excursion the

driver was producing made it appear as if the cone would jump right out of the

box! These E series drivers are not your average bass drivers that is for sure.

The protection and overload circuitry in the E series must be exceptionally

well dialed in also as even the largest most powerful and expensive subwoofers

I have reviewed thus far have had trouble with some of these demo scenes.

I was quite impressed with the E series and their performance with both music and movies. Both deliver smooth, balanced sound and offer an amount of headroom that is a bit unexpected. Both performed flawlessly with anything I threw at them. It should come as no surprise that the e110 and larger e112 both perform and sound almost identical to each other. Listening to both back to back in the same room they were almost indistinguishable unless pushing them hard enough that the e112 could show its advantage in the deep bass where it has a bit of extra headroom over the e110 as one would expect.

JL Audio E-Sub e110 and e112 Subwoofers Measurements & Analysis

The JL Audio e110 and e112 subwoofers were both measured while placed outdoors on the ground in a large field with the nearest large objects a minimum of 60ft or farther away from it, with the driver facing towards the microphone element. The left RCA input was used and an ACO Pacific 7012 measurement microphone was placed on the ground at a distance of 2 meters from the nearest enclosure face of the subwoofer and pointing towards the driver. The amplifier was set to maximum gain, the phase was set to zero and the low pass filter was set to bypass for all measurements unless otherwise noted. For more info on the testing equipment and procedures please see the article here.

Powered Subwoofer Testing Outline and Procedures Overview

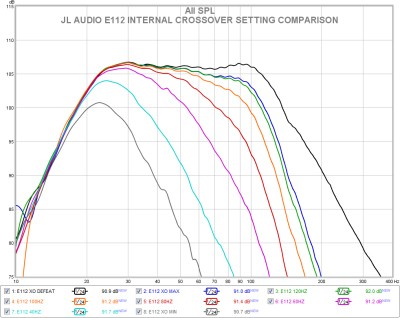

JL Audio e112: Effect of Low Pass Filter Settings on Frequency Response

Above are the frequency response measurements of the e112 subwoofer showing how adjustment of the internal low pass filter affects the top end response shape. The roll off slope is 24dB/octave. The resulting roll off point was a bit below that indicated by the setting on the dial. The e110 subwoofer performed in a very similar manner so its results will not be shown.

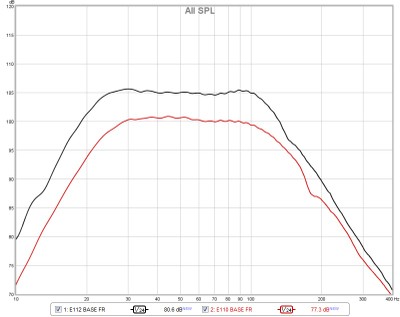

JL Audio e110 and e112: Basic Frequency Response as Tested

Above is the frequency response of both the e110 and e112 subwoofers with the internal low pass filters disabled. The shape and slope of the roll off on the low end of both the e110 and e112 indicate that there is some low frequency boost employed internally and that there is what appears to be a 12dB/octave high pass filter that comes into effect below 20Hz and combines with the sealed systems natural 12dB/octave roll off to produce a 24dB/octave total slope. The e112 response fits within a 6dB total window from 19-135Hz. The e110 fits within the same 6dB total window over a frequency range of 21-143Hz. The overall response shape of both systems is fairly close with the e112 having a bit of extra low-end extension. Even with the low pass filter defeated on both units the top end extension is fairly limited but is enough so that the crossover point to the other speakers in the system could be effectively set to around 130Hz.

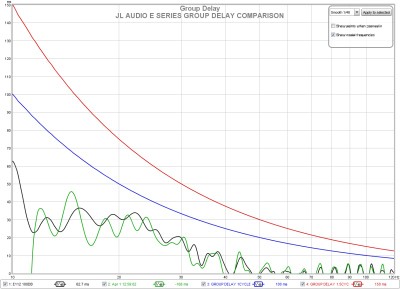

JL Audio e110 and e112: Group Delay

Group delay measurements for the E series JL’s are well mannered and show nothing of consequence. Neither subwoofer approaches 1 cycle of delay at any point over its entire useful bandwidth.

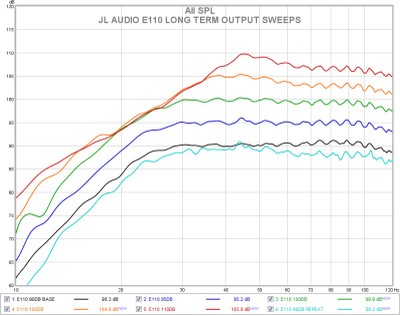

JL Audio e110: Long-Term Power Compression

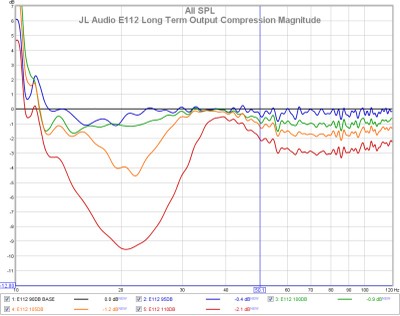

JL Audio e112: Long-Term Power Compression

The long-term output compression tests for the smaller e110 subwoofer show negligible compression through the nominal 100dB sweep. Compression sets in first in the 20-25Hz area and by the 110dB nominal sweep the e110 is out of headroom full bandwidth. The little e110 manages to produce more than 93dB at 20Hz, passes 100dB at about 28Hz and produces over 105dB above 35Hz during the loudest sweep. The e112 performs quite similarly to the smaller e110 but exhibits greater low bass power. It also remains free of significant compression through the 100dB nominal sweep before exhibiting compression in the 20-25Hz area during the 105dB nominal sweep. By the 110dB nominal sweep it is out of gas. The bigger e112 leverages the larger driver and a bit of extra stroke to manage about 97dB at 20Hz, 101dB at 30Hz and about 109dB at 38Hz. Both subwoofers exhibit some thermal compression from heating of the voice coil in the repeat 90dB base level measurement conducted immediately after the rest of the measurements. Neither subwoofer made any overtly bad noises during these measurements. Other than a bit of distortion and a bit of “grumble” and distortion from the drivers near 20Hz on the loudest sweeps, there was no distress to report. The E series subs are very well protected against being overdriven or otherwise damaged.

Note on Output Compression Testing: This is by far the most demanding measurement type conducted on the subwoofers during our testing and will reveal any issues with overload, port compression, port noise, driver distress, creaks, rattles, buzzes, etc. Additionally the test is conducted outdoors with just the subwoofer operating so there will be no nearby walls or objects to vibrate and no upper frequency content from other speakers in operation. These would normally help to cover up or mask any objectionable noises from the subwoofer in a typical room. Any sort of audible distress or issues with the subwoofer are readily apparent in this environment.

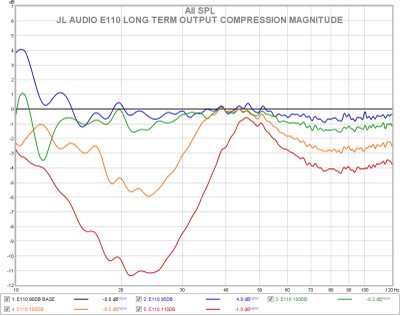

JL Audio e110: Output Compression Magnitude

JL Audio e112: Output Compression Magnitude

Looking at the amount of compression occurring in the e110 and e112 subwoofers in the graphs presented above shows that both are very well behaved until the 105dB nominal sweeps where both start to exhibit notable compression near 20-25hz as both are out of output in this frequency range. Asking the E series subwoofers for a further 5dB increase in output past this point causes them to fall into compression in the upper bass register as well where the output is now some 3 to 4dB less than it should be. As noted previously neither subwoofer showed any signs of being in danger of damage by driving them this far into compression. Judging from the measurement data as a whole it appears that both subwoofers employ significant boost in the 20-25Hz region to flatten their response.

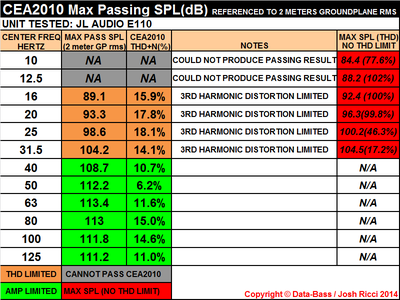

JL Audio e110: CEA2010 2 Meter Ground-plane RMS Results

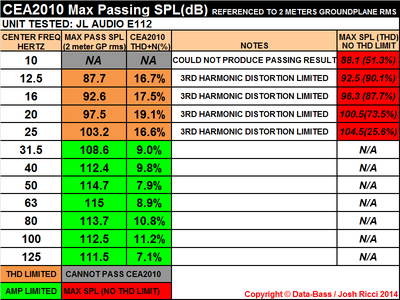

JL Audio e112: CEA2010 2 Meter Ground-plane RMS Results

CEA2010

Results

The CEA2010 maximum-distortion-limited-short-term output results for the JL Audio E series subwoofers are shown above. The e110 is a mighty little beast. It manages to produce well over 110dB from 50-125Hz which would explain why it packs quite a thump with kick drums. On the low end it still manages a passing 93.3dB at 20Hz and even manages a passing 16Hz at 89.1dB. Not exactly records by any means but for a single sealed 10” driver it is more than respectable. At 31.5Hz and above the e110 was amplifier limited and below that the distortion was the limiting factor as the e110 will put out a bit more in the deep bass if distortion is ignored. Pushing it for all it is worth at 20Hz it will muster up about 96dB. The bigger e112 with a 12” driver and slightly stronger amplifier puts out a little more as expected. At 63Hz the e112 managed to burst 115dB flat and is still well over 110dB at 40Hz. In the deep bass is where the larger driver, enclosure and amplifier of the e112 come into effect. This allows the e112 to produce about 3-4dB higher maximum output than the e110 below 40Hz. The e112 produced 97.5dB at 20Hz and 92.6dB at 16Hz while passing the CEA-2010 distortion thresholds. It even managed a passing score of 87.7dB at 12.5Hz. As with the e110 the e112 was amplifier limited above the 31.5Hz band but was distortion limited below that point and would produce another 3-4dB if pushed to its limit in the deep bass. Maximum output at 20Hz was recorded as 100.5dB without regard for distortion. When comparing the CEA-2010 short-term burst output to the maximum outputs reached during the sine sweep testing reveals that the E series exhibits 3 to 5dB of extra output with shorter term signals. This may be partly due to a protection circuit that dials back the power when the signals are of very long duration in order to prevent overheating of the voice coil.

JL Audio E-Sub e110 and e112 Subwoofers Conclusion

After

spending many months with the E series subs in my home I can say with certainty

that JL Audio has produced a very fine product in the e110 and e112 subwoofers.

I struggled to even come up with something to put in the column for “Cons”. These

have some of the best fit and finishing I’ve seen on any speaker and they are

so small that they should fit into anyone’s room. On my review units everything

was tight and had the feel of quality. They were rock solid no matter what I

put them through. Even throwing some of the most abusive low frequency signals

around into their input jacks did not faze them. I have had opportunity to hear

the Fathom F112 and F113 on a few separate occasions and I always came away

with a positive impression but the E series was supposed to be JL’s slightly

less expensive line and I have to say I may be more impressed with them. These

subwoofers are very simple in operation with only the traditional controls

which I am a big fan of. A lot of the extra “fluff” included with some

subwoofers these days is of very questionable value in my estimation and

certainly increases the price tag. Yes these are not budget subs but one look

at pictures of this driver and it should give some indication of where JL

thought that the money would best be spent in the E series design. The

amplifier is also a quality unit that packs quite a wallop. With tiny sealed

subwoofers there is only one way to get deep bass output out of them and that

is with a high displacement driver and a lot of amp. Both of these things of

course increase the costs. If you want a small subwoofer with big output you

will have to pay for it. There is no way around it. JL Audio has managed to

squeeze an amazing amount of output out of the E series subs. Most of the subwoofers

I’ve encountered in this size class I have a hard time even considering real

subs as they are so limited in output

and extension, but the e110 made me re-evaluate my stance on how small a

legitimate subwoofer could be. I give a tip of the hat to the JL Audio

engineering team as they really nailed it with the E series. The E series JL

Audio subwoofers may be one of the best options on the market for those in need

of a small yet powerful bass system.

After

spending many months with the E series subs in my home I can say with certainty

that JL Audio has produced a very fine product in the e110 and e112 subwoofers.

I struggled to even come up with something to put in the column for “Cons”. These

have some of the best fit and finishing I’ve seen on any speaker and they are

so small that they should fit into anyone’s room. On my review units everything

was tight and had the feel of quality. They were rock solid no matter what I

put them through. Even throwing some of the most abusive low frequency signals

around into their input jacks did not faze them. I have had opportunity to hear

the Fathom F112 and F113 on a few separate occasions and I always came away

with a positive impression but the E series was supposed to be JL’s slightly

less expensive line and I have to say I may be more impressed with them. These

subwoofers are very simple in operation with only the traditional controls

which I am a big fan of. A lot of the extra “fluff” included with some

subwoofers these days is of very questionable value in my estimation and

certainly increases the price tag. Yes these are not budget subs but one look

at pictures of this driver and it should give some indication of where JL

thought that the money would best be spent in the E series design. The

amplifier is also a quality unit that packs quite a wallop. With tiny sealed

subwoofers there is only one way to get deep bass output out of them and that

is with a high displacement driver and a lot of amp. Both of these things of

course increase the costs. If you want a small subwoofer with big output you

will have to pay for it. There is no way around it. JL Audio has managed to

squeeze an amazing amount of output out of the E series subs. Most of the subwoofers

I’ve encountered in this size class I have a hard time even considering real

subs as they are so limited in output

and extension, but the e110 made me re-evaluate my stance on how small a

legitimate subwoofer could be. I give a tip of the hat to the JL Audio

engineering team as they really nailed it with the E series. The E series JL

Audio subwoofers may be one of the best options on the market for those in need

of a small yet powerful bass system.

The JL Audio e110 subwoofer easily meets the specified output thresholds to receive the Audioholics Bassaholic Medium Room rating but can’t quite meet the requirements to get the large room rating. Its larger brother the e112 was able to meet the output requirements needed to garner the Audioholics Bassaholic Large Room rating. The Medium room rating indicates that this sub is recommended as maintaining adequate headroom in rooms or spaces of 1,500-3,000 cubic feet and/or for users who usually listen at moderate volume levels. The Large room rating indicates that this sub is recommended as maintaining adequate headroom in rooms or spaces of 3,000-5,000 cubic feet and/or for users who usually listen at moderate volume levels with occasional high volume playback. For further information in how we make these recommendations see the full article here.

JL Audio e112 Subwoofer Youtube Review

See: Audioholics Subwoofer Room Size Rating Protocol

JL Audio e110 JL Audio e11

MSRP:

$1500-1700 (e110)

MSRP:

$1900-2100 (e112)

The Score Card

The scoring below is based on each piece of equipment doing the duty it is designed for. The numbers are weighed heavily with respect to the individual cost of each unit, thus giving a rating roughly equal to:

Performance × Price Factor/Value = Rating

Audioholics.com note: The ratings indicated below are based on subjective listening and objective testing of the product in question. The rating scale is based on performance/value ratio. If you notice better performing products in future reviews that have lower numbers in certain areas, be aware that the value factor is most likely the culprit. Other Audioholics reviewers may rate products solely based on performance, and each reviewer has his/her own system for ratings.

Audioholics Rating Scale

— Excellent

— Excellent

— Very Good

— Very Good

— Good

— Good

— Fair

— Fair

— Poor

— Poor

| Metric | Rating |

|---|---|

| Bass Extension | |

| Bass Accuracy | |

| Build Quality | |

| Fit and Finish | |

| Ergonomics & Usability | |

| Features | |

| Dynamic Range | |

| Performance | |

| Value |