Myths & Facts about Loudspeaker Cabinets: Identifying Legitimately High Fidelity Designs

Anytime a product is offered to a consumer, it's bound to be wrapped in marketing to help bolster its appeal and differentiate it from the competition. Quite often the marketing tactics used by manufacturers contain a hint of truth with embellishment and sometimes simply have no basis in reality at all (otherwise known as “creative” marketing). When it gets to this extreme, you often hear us call such claims "snake oil.” This is quite popular when dealing with exotic cables but we've also found it a routine practice with loudspeakers and A/V electronics as well. What makes "creative marketing" dangerous is when it is presented under the guise of science. This article explores some of the common myths we've uncovered in loudspeakers and discusses how poorly executed decisions can ultimately compromise the quality of the product.

The reader is also encouraged to check out our prior article of this series:

It’s important to note that identifying truly high fidelity loudspeakers involves controlled listening tests and comprehensive and accurate measurements that correlate with how humans perceive sound. We will dive into this further in our Audio Measurements & Myths article forthcoming. Make no mistake however that making a truly great speaker involves truly great parts and design execution. One cannot expect a 150hp 4-cylinder sedan to beat a super car on a track since it lacks the performance parts and sturdy frame. The same applies to loudspeakers. The sum of the parts really does matter as does the engineering behind making all of the parts work together as one unit.

Myth #1: Internet Direct buying is ALWAYS a better "value" than buying through a Brick and Mortar retail store

A

common perception is that buying from an Internet Direct brand lowers the cost

of distribution profit margins, yielding a higher value to you, the

consumer. Over the past 11+ years of

reviewing loudspeakers, we at Audioholics have found this is often NOT the

case. In many instances, we've found the

build quality and parts usage from an Internet Direct brand vs a traditional

Brick & Mortar brand is either on par or worse when directly comparing

products in the same price categories.

Ask yourself why anyone would cut their margin on a product when they

can justify the price and convince the end user they are getting a better deal

simply because they are buying direct and allegedly cutting out the middle

man? While it is possible to get a

better deal direct, it is not a foregone conclusion, hence why it's

important to look at the quality of parts inside the box.

A

common perception is that buying from an Internet Direct brand lowers the cost

of distribution profit margins, yielding a higher value to you, the

consumer. Over the past 11+ years of

reviewing loudspeakers, we at Audioholics have found this is often NOT the

case. In many instances, we've found the

build quality and parts usage from an Internet Direct brand vs a traditional

Brick & Mortar brand is either on par or worse when directly comparing

products in the same price categories.

Ask yourself why anyone would cut their margin on a product when they

can justify the price and convince the end user they are getting a better deal

simply because they are buying direct and allegedly cutting out the middle

man? While it is possible to get a

better deal direct, it is not a foregone conclusion, hence why it's

important to look at the quality of parts inside the box.

Smaller companies are always at a competitive disadvantage when it comes to offering value because their purchasing power and therefore negotiating power is less than that older more established company which can place a 10,000 piece order. This is one of the primary reasons many smaller sized businesses choose to get into the higher end of the market. While sales are less, margins are higher. Smaller companies can do some things better, like make decisions more quickly than a big company with a lot of different departments who all want to have their say. That is a plus for the small guys of course, but only when they have made the right decisions. That said, larger companies can afford to have elaborate engineering facilities that smaller companies cannot. That does not guarantee better sounding products – that requires the additional factors of desire, knowledge and competent engineers - but at least there is the potential. Many small loudspeaker companies, even those in the “high end”, lack the facilities to adequately or fully measure their products. This can hardly be considered an advantage, and it helps explain the significant number of overly expensive mediocre sounding “high end” loudspeakers in circulation over the years.

Every company attempts to find a “sweet spot” between the best product they can make, and the least expensive they can profitably sell. Those companies with little or no engineering inevitably go into the bargain basement for products. Those who know nothing about the products they sell, still know price. The avenue of least resistance for a small company is usually to pick a niche in the high end, high margin market. They simply do not have the resources to compete with a much larger, older and well funded company. That means, if the engineering is top notch, you can and will find a good value. If not.... move on.

Bottom Line: First find a speaker system you like the sound and looks of and then work on getting a good price. Don't blindly assume any company which is large and long established will provide you a better value product. Name recognition may give you warm fuzzies, but is more likely to cost you than to get you the best bang for your buck! Also remember a poorly designed $600/pair of speakers discounted to $300/pair still doesn’t change the fact that they are poorly designed.

Cabinets Myths & Facts

The purpose of the loudspeaker cabinet is two-fold, to provide a controlled acoustical enclosure for the drivers to operate most efficiently, and to provide a physical structure to hold all of the drivers in place while positioning them optimally for the listener. Let's explore some of the common myths and facts that distinguish the very best designs.

Myth #2 : Premium quality cabinet construction does not require premium materials or workmanship

It is

often the case that the cabinet costs considerably more than the components it

houses. This was not always the case,

but as increasing competition drops the prices of the raw loudspeaker drive

units, deforestation and the cost of fuel and labor keeps driving up the cost

of high quality materials used in speaker cabinets. It is no longer uncommon for a $100 box to be

housing $20 worth of components. The

continuing emphasis on looks over sound quality reinforces the manufacturers

decisions in this regard. Frankly after

25 plus years in the business, I am amazed that this one even has to be raised.

It is a fact when using sensitive test gear to measure a woofer’s Theile-Small

parameters, we have to hold it with something very rigid and heavy, or else the

counter motion of the shaking test fixture will degrade our measurements. How is it then, if the enclosure would have

panels resonate at a lower frequency (read more box motion) that this could

really be a good thing? Cheap fiberboard

will flex more than will a good grade of plywood or MDF. Thicker is better than thinner. The reasons that MDF gets used over plywood

is price, not necessarily quality. The joints and

gluing of different pieces inside the cabinet is also not something you can

tell without poking around inside the box.

Taking shortcuts on enclosure construction is a quite typical way

manufacturers cut costs. A consumer is

not likely to see these shortcuts until after their purchase. The knuckle test, unlike tire kicking

(performed at various locations around the cabinet panels), can certainly tell

you if the box is rigid from the pitch of the sounds it makes when

knocked. Unfortunately, it won't tell

you anything about air leaks or port losses and it’s obviously not an exact

science. A scanning laser vibrometer or even an accelerometer is

a tool some of the larger more equipped companies can use to better analyze

cabinet resonances since it analyzes the pressure fluctuations over the distributed

surface where the woofer radiates. It’s important to look at a full battery of

measurements at various power levels to see how the loudspeaker behaves. When we do loudspeaker reviews, we typically

sweep the speakers with a full bandwidth, long sine wave at high output levels

to look for such sonic nasties that can really inhibit product

performance. Pay close attention to the

measurements section of our reviews as we report these issues when they

arise.

It is

often the case that the cabinet costs considerably more than the components it

houses. This was not always the case,

but as increasing competition drops the prices of the raw loudspeaker drive

units, deforestation and the cost of fuel and labor keeps driving up the cost

of high quality materials used in speaker cabinets. It is no longer uncommon for a $100 box to be

housing $20 worth of components. The

continuing emphasis on looks over sound quality reinforces the manufacturers

decisions in this regard. Frankly after

25 plus years in the business, I am amazed that this one even has to be raised.

It is a fact when using sensitive test gear to measure a woofer’s Theile-Small

parameters, we have to hold it with something very rigid and heavy, or else the

counter motion of the shaking test fixture will degrade our measurements. How is it then, if the enclosure would have

panels resonate at a lower frequency (read more box motion) that this could

really be a good thing? Cheap fiberboard

will flex more than will a good grade of plywood or MDF. Thicker is better than thinner. The reasons that MDF gets used over plywood

is price, not necessarily quality. The joints and

gluing of different pieces inside the cabinet is also not something you can

tell without poking around inside the box.

Taking shortcuts on enclosure construction is a quite typical way

manufacturers cut costs. A consumer is

not likely to see these shortcuts until after their purchase. The knuckle test, unlike tire kicking

(performed at various locations around the cabinet panels), can certainly tell

you if the box is rigid from the pitch of the sounds it makes when

knocked. Unfortunately, it won't tell

you anything about air leaks or port losses and it’s obviously not an exact

science. A scanning laser vibrometer or even an accelerometer is

a tool some of the larger more equipped companies can use to better analyze

cabinet resonances since it analyzes the pressure fluctuations over the distributed

surface where the woofer radiates. It’s important to look at a full battery of

measurements at various power levels to see how the loudspeaker behaves. When we do loudspeaker reviews, we typically

sweep the speakers with a full bandwidth, long sine wave at high output levels

to look for such sonic nasties that can really inhibit product

performance. Pay close attention to the

measurements section of our reviews as we report these issues when they

arise.

Editorial Note by Philip Bamberg

I've always said that the first, and last, problem in manufacturing speakers is making the cabinet. Materials cost aside, the largest cost remains the high labor hours. This may be one reason many cabinets from all companies (whether high or low priced) are coming from China. The low labor rate makes the cabinet more affordable if ordered in container quantities. Whether the speaker is assembled domestically or overseas, more and more cabinets are coming out of China. However, the Chinese will build whatever designers want, so that does not mean that all Chinese cabinets are inferior.

Editorial Note by Steve Feinstein

There are, in fact, several grades of MDF in China. There is “good” MDF and “not-so-good” MDF from Asian suppliers. You have to be careful to specify and confirm that you’re getting what you expect. You can get perfectly excellent cabinets from overseas, but it's not automatic. The same is true of packaging material. Standard box material is sometimes jokingly referred to in the U.S. as "rice paper." You have to specify a multi-layer high-burst-test material to get really good corrugated box material. A manufacturer must be smart and aware of the potential pitfalls.

Bottom Line: You get what you pay for in terms of quality of craftsmanship and parts. Don’t expect Mercedes performance from a Kia budget.

Myth #3: Less cabinet bracing is better because it lowers resonant frequency and audibility

It is argued that if too much bracing is applied, a higher resonant point will result making any cabinet resonances more audible. While it is true that a higher cabinet resonance at a given SPL is going to be more audible (dismissing the possibility that that resonance will ever be over 3.5 kHz) the reality is that the physical coupling of the speaker to the cabinet is going to make frequencies accompanied by higher excursions (read lower frequencies) more problematic and more likely to result in panel excitation than a high Q resonance at a higher frequency. A stiffer cabinet will simply color the sound less. PERIOD. Less glue, less staples, less screws, and/or less bracing and less effort go into a cheaper cabinet making the enterprise more profitable at a given price point. It is a much faster process to throw the cabinet together quickly than to take the time to do it right. The last and final bonus of that approach is the reduction in weight, which is always going to reduce the cost of shipping.

Tower speakers with no internal bracing (left pic); bookshelf speaker with baffle bracing (right pic)

The left image is from a European speaker costing over $2k/pair and standing 4ft tall. This box has no internal bracing at all and very mediocre crossover components. The manufacturer has since then discontinued the product after we did an exposé on the poor design quality, and has made significant improvements on the current versions being sold. The right image is from a center channel speaker less than 1/2 the size of the tower speaker of the left image. Notice the baffle bracing. The poly fill was removed from the cabinet for a clearer image of the bracing.

It all comes down to the mechanical properties of the materials with which the cabinet walls are built, the geometry of the panels and how they are affixed to one another. We discuss this in great detail in:

- Lowering the Mechanical Noise Floor in Loudspeakers Part I

- Lowering the Mechanical Noise Floor in Loudspeakers Part II

Editorial Note by Philip Bamberg

Bracing essentially breaks up a larger panel into multiple smaller ones, each with a higher resonant frequency AND lower excursion. Even if a panel motion is small, its radiating area is still large. The solution is to reduce its excursion through bracing. Also, there are many examples of deficient interior brace design i.e. that do not properly “cross-couple” opposing panels. In other words, the corners have the most support (where they need it the least) while the middle areas have no coupling to the opposing panel. Adding thickness to panels add weight, which lowers the frequency of resonance. If the panel increases in stiffness then there is the chance that the panel vibration amplitude will also decrease. Therefore thicker panels alone do not solve the vibration problem. Stiffness must also increase, and this is done most effectively with cross-coupled bracing.

One of the more disturbing trends caused by the notion that the appearance is more important than the speaker sound is the all too common routing (cutting away) of the front baffle board so the front of the speaker frame is flush with the front of the baffle (front board of the cabinet). Now it should go without saying, the place where structural rigidity is most important is where the woofer screws into the box. Despite this, for the sake of looks, not performance, the vast majority of cabinet makers think the box in the one place where the need for rigidity is highest; and where the most weight and force exerted on the cabinet are concentrated, at the place the woofer is mounted to the cabinet. Any motion that is going to occur which results in shaking the cabinet instead of exciting the air, is going to result in at best a coloration in the sound, and at worst, a some loss of output. To help overcome this, the front baffle must be made thicker so it’s a good idea to verify just how thick not only the cabinet panels are, but more importantly, the front baffle. Good boxes typically have a thick front baffle. Thickening the front baffle helps mass load and dampen vibrations coming off the driver basket which in turn reduces its transfer to the rest of the cabinet. A box made of 3/4" MDF might have a 1" front baffle. In other words, if one is inclined to route the front panel, one should usually increase the baffle thickness to retain an adequate degree of rigidity to compensate for flush mounting the drivers. Ask for this info when shopping for new speakers if the manufacturer doesn’t provide specifications.

Editorial Note by Philip Bamberg

Making the front baffle thicker than the other panels may not always be the most effective approach, especially in cases where much of the front baffle may be cut away where the drivers are. That part of the baffle can’t vibrate because it doesn’t exist! In those cases, my approach is to properly brace the backside of the baffle near the driver cutouts, instead of making it overly thick. Such a baffle will typically produce the highest pitch of all the cabinet panels during the knuckle-rap test.

If it’s a subwoofer with a high excursion driver, you should expect an even thicker front baffle. An example of a well engineered cabinet comes to mind with the SVS PB13-Ultra subwoofer we recently reviewed that had 1" side panels and a 2" front baffle and plenty of bracing to increase cabinet rigidity.

Editorial Note by Philip Bamberg

For subwoofers, there is the added problem of supporting the heavy woofer. Vibration and insufficient support of the driver is not necessarily the primary concern. It really is more a matter of strength during an accidental drop during shipping. A thick subwoofer baffle flexes less and has more glue surface to the other panels. These features put less strain on the cabinet joints. Very heavy subwoofers need an additional brace that supports the motor itself. Otherwise high forces (static and dynamic shear and torque forces) develop during a shipping drop. Sometimes the cabinet cracks open, other times the woofer motor or basket parts shear apart. The supporting brace typically prevents these problems.

Consider mounting a loudspeaker in a box made of simple paper, and imagine how it would sound! Imagine the paper flapping when you turn on the loudspeaker. Clearly, the lack of rigidity would make this cabinet sound awful. Any ideal mounting for a loudspeaker would be an infinitely rigid surface. Only in this way will we insure that the motion of voice coil and cone results in sound, not a volume canceling offset of motion from the cabinet, or the excitation of a panel resonance adding to and coloring the original signal. Some manufacturer's have actually gone to the trouble of making their cabinets out of marble or granite and even concrete in order to come closest to this ideal. The idea that making the cabinet better by giving it a lower panel resonance (which means thinner walls) is at best amusing, and at worst, simply a deception.

Editorial Note by Philip Bamberg

There is improved imaging and low-level detail to be gained from heavy speakers, simply because they “hold still” during high playback levels. I think there is a point of diminishing returns to this concept, however. Taken to extreme there is the myth that the best loudspeakers must weigh several hundred pounds.The action-reaction of a cabinet moving even slightly tends to degrade imaging accuracy, low-level resolution, and sense of “bloom”. It is the same effect as compression of the signal to the driver, because the full peak cannot be reached. Heavy, rigid cabinets on spikes will sound more accurate for any given driver complement.

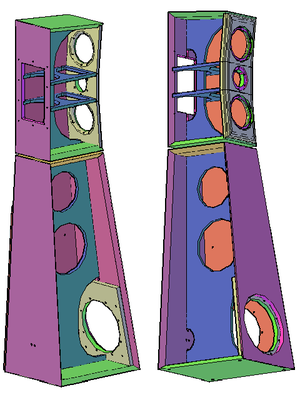

Here is an example where three different methods lead to stiff panels with low amplitude and high resonance frequency.

Method 1 – Cross-coupled interior bracing

The interior braces are shown as blue panels. In all cases, each brace ties two opposite panels together. At the brace glue joint itself, the two panels cannot vibrate. The unsupported panel areas are obviously smaller in size than without bracing, hence any vibration is higher in frequency but much smaller in amplitude. Notice also how the braces may have a thinner profile in the middle of the cabinet, but the brace’s full edge gets glued to the panel. This concept is what leads to the D-shape of each brace’s profile.Method 2 – Increased panel thickness

In the example subwoofer cabinet, the front panel is double-thickness (1.5” MDF) where the woofer installs. This is to recess the woofer to give clearance for the grille, plus provide proper and sufficient support for the heavy 10” subwoofer driver. (Above this board, the front panel is single thickness again, but supported by the large vertical “spine” brace.) The side panels are dual 3/4" MDF thickness up to about 3/4 of the subwoofer cabinet’s height. The side panels are the largest of all in the loudspeaker, and they do not have cross-coupled bracing.Method 3 – Material intrinsic stiffness

The passive crossover is mounted onto a 1/4” thick aluminum bezel plate, which is then installed into the open window on the back of the monitor cabinet. Here is an example of a very thin panel (1/4”), but of very stiff material (6061 T6 aluminum).Also, while the monitor baffle is 1” thick, it is made from a sandwich of two 1/2" MDF layers. This is because there are four hardened skins instead of two, and so the baffle material becomes intrinsically stiffer. The baffle is supported all around its edges by the box, and further stiffened from the two horizontal D-shape braces glued at the webs between the woofers and tweeter.

Cabinet of Bamberg Series 6 Internal View

Editorial Note by Steve Feinstein

Many speaker enclosures or tweeter decorative faceplates are made out of materials other than MDF or aluminum. A large number of speakers are made from molded plastic or a combination of MDF and molded plastic. Obviously thin-walled ABS plastic (4mm or less) is not the greatest material for suppressing resonances and destructive vibrations, but cosmetics and appearances play such a big role in the mid- and lower-price ranges that looks often take precedence over absolute acoustic performance.Reality is reality, but there are still common-sense steps that a designer can take to make the best of a given situation. Stiffening ribs help a lot and usually add relatively little to the “tooling costs” that a manufacturer must pay for the plastic molding apparatus. Also, if the developmental budget allows, the plastic material itself can be optimized with hardening agents (like mineral or talc) added to the plastic that makes it less “ringy.” That way, the industrial designer/marketing department can still get their fancy, attractive shape, but the engineer won’t cringe quite as much over the acoustic properties of the enclosure or faceplate.

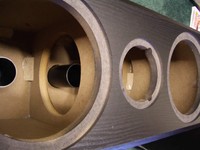

RBH Sound Status Acoustics Subwoofer Enclosure - inside look

RBH Sound new cost no object Status Acoustics line of speakers feature a layered acoustically inert enclosure construction. This method of construction involves bonding multiple layers of materials together and allows the wall thickness of the enclosure to be varied without the limits imposed by more traditional panel construction. When needed, bracing for the enclosure is integrated into the layered design. The end result is an enclosure that is extremely acoustically inert. Doing this also allows the manufacturer more ability to shape the cabinet design to their liking. There are some downsides prohibiting this type of construction for most manufacturers. It involves a very costly process that uses a lot of materials to produce and it results in a very heavy cabinet which is expensive to ship.

Bottom Line: Increasing cabinet rigidity is always a good thing. This can be accomplished by using interior bracing, thicker panels, and/or more dense materials. If a company tells you using less bracing to lower cabinet resonance is beneficial, recognize that at worst case they simply don't have a good grasp of the mechanics involved; and at worst case are attempting to rationalize their cost cutting methods. This is especially true for companies that sell direct and offer free shipping with their products. Adding more bracing complicates and slows the production of the product, and adds more weight to the finished product which means more cost!

Identifying Legitimately High Fidelity Loudspeakers: The Cabinet Face & Stuffing

Why Flush Mount Drivers? The

best reason for flush mounting a driver is to keep the frequency response

smooth. Having a sudden transition in the geometry of the surface on which the

speaker is mounted is the fastest way to cause aberrations in your frequency

response. For this reason, it is far

more justifiable to flush mount a ½ pound tweeter with a 3/8ths inch thick plastic

mounting ring, than it is to flush mount a cast frame 12 inch woofer, with a ½

thick aluminum frame covered by another ¼ inch of gasket sticking above the

frame. Remember too that the importance

of this is a function of the size of the frequency range of the speaker. Higher frequencies = shorter wavelengths

radiated, so that this small fraction of an inch is around 133 degrees at 5kHz,

(37% of a wavelength) while at 500 Hz, we are talking about 13.3 degrees or

3.7% of the size of the wavelength. At

50 Hz, this is only 1.33 degrees or 0.37 percent of your wavelength. Flush mounting may be justified for the

tweeter, but doing it for the woofer is more a matter of aesthetics. As mentioned prior, care must be taken to not

have it penalize performance by ensuring the front baffle is thickened to

counter the lost rigidity associated with flush mounting the driver.

The

best reason for flush mounting a driver is to keep the frequency response

smooth. Having a sudden transition in the geometry of the surface on which the

speaker is mounted is the fastest way to cause aberrations in your frequency

response. For this reason, it is far

more justifiable to flush mount a ½ pound tweeter with a 3/8ths inch thick plastic

mounting ring, than it is to flush mount a cast frame 12 inch woofer, with a ½

thick aluminum frame covered by another ¼ inch of gasket sticking above the

frame. Remember too that the importance

of this is a function of the size of the frequency range of the speaker. Higher frequencies = shorter wavelengths

radiated, so that this small fraction of an inch is around 133 degrees at 5kHz,

(37% of a wavelength) while at 500 Hz, we are talking about 13.3 degrees or

3.7% of the size of the wavelength. At

50 Hz, this is only 1.33 degrees or 0.37 percent of your wavelength. Flush mounting may be justified for the

tweeter, but doing it for the woofer is more a matter of aesthetics. As mentioned prior, care must be taken to not

have it penalize performance by ensuring the front baffle is thickened to

counter the lost rigidity associated with flush mounting the driver.

Editorial Note by Philip Bamberg

Well said. Flush mounting the midbass woofer is also desirable so that its frame does not otherwise disturb the tweeter sound.

The Importance of a Smooth Cabinet Face & Grille Design

For the same reason we justify flush mounting, we can point to an easy way to see if the manufacturer has made extra efforts in finishing the system in a way that will yield the best results by simply examining the grille construction and cabinet face. If the cabinet edges are square, they have made the simplest and cheapest box they can. For a sub, that may be perfectly ok, but a full range speaker is another matter. The best shape of all for a cabinet would be spherical, but this is not a solution wood lends itself to easily. The next best solution is a truncated pyramid. This is achieved by either chamfering or rounding the edges of the corner of the front of the cabinet. The larger the radius we can use on a box of a given size (spherical would be the largest) the less of an issue we are going to have (in general) with the wavelength suddenly transitioning from 2pi to 4pi (hemisphere bounded by the baffle dimension to bubble enveloping the entire box). A good system designer will take care to be sure his transition from front baffle to sides is slow and tapered to minimize cabinet diffraction and frequency response aberrations due to cabinet shape and size. The attention to the detail given in the shape of the box, and the location of the drivers on the baffle are important to the final system response. Mounting a driver in the center won't make for the smoothest possible response for a typical monopole driver alignment, but saves the manufacturer from having to make separate left and right speakers. (Saving cost in production at the expense of sound quality). Chamfering the edges of the enclosure will minimize the effects of diffraction, and smooth out the response of the box both on and off axis. It is more complicated and complex, but it is worth the effort.

Editorial Note by Philip Bamberg:

It turns out that the transition at the forward cabinet edges has to be substantial to gain a substantial smoothing of the treble response. This is a more expensive option that manufacturers weigh during product planning. Cabinet edge diffraction creates other delayed phantom sound sources which can obscure detail in the treble. A gradual transition spreads out the phantom source both in dispersion angle and over a wider frequency band. Both effects cause the disturbance to be lower in SPL to the listener.

Probably the most common issue with commercially made boxes is how many simply have awful grilles which cause HUGE aberrations in the frequency response. You would likely be surprised and amazed both at how much a grille causes problems in the response of your system especially one which is thick and protrudes in front of the speakers. I have found that a large majority of systems get voiced without the grille, and then when readied for market, a grille is put together without regard to how it affects the overall frequency response of the speaker. Maybe it is not considered important, or maybe the overriding issue is cost, but this happens often enough to make me wonder about the creative process. The best grilles will be thin, not protrude In front of the speaker, and are integrated into the box shape and design. Very often it is the thinnest most structurally minimalist designs which give the best results.

Editorial Note by Philip Bamberg

True. And contouring the inner edges really helps, too. Thank goodness typical MDF grilles are removable! Grilles on for casual listening; grilles off for involved listening.

My testing has shown the detrimental effect of the grille’s presence to be much more benign with perforated metal grilles than the customary MDF grilles. The SPL response is very close to the grille-off situation across a wide off-axis window. I don’t care for their appearance in that they have been associated with architectural or cheap speakers. But grille cloth can be applied to them, too. (Note that grille cloth causes slight waveform compression in the top two octaves and is why the driver sounds “softer” when behind grille cloth.

Comparing Cabinet Materials

The vast majority of cabinets made for consumer audio today are constructed from MDF, (short for Medium Density Fiberboard). This is basically sawdust held together under heat and pressure with a great deal of glue. Many years ago it was not uncommon to find budget systems using particle board, which came apart very easily, especially if you had to remove and replace a screw holding a speaker in more than 1-2 times. Particle board (made from small chips of wood) is now essentially unheard of in anything likely to be used for even a budge hi-fi system. High end cabinets are often constructed from veneered plywood which is both less likely to flex (because the layers are laid down where the grain of the wood is perpendicular between adjacent layers). The best commonly available plywood for loudspeaker boxes is marine grade which is free of voids (small holes or knots in the layers). Better grades of plywood of a given thickness will use more plys for greater rigidity. Inexpensive plywood generally costs about twice as much per sheet than does MDF of similar thickness. (Depends on the number of plys used, and what if any veneer is used). The standard thickness used in most loudspeaker cabinet construction is 3/4” thick (19mm), although some manufacturer's make it a point to double the thickness of the front baffles, especially when they are loaded with very heavy subwoofers. The added rigidity and weight both aid the speaker in producing less coloration from the cabinet. Remember, if the cabinet moves, that means the energy which should be creating sound is creating motion of the enclosure instead! If you do a bit of research online, you will notice that there is an even higher grade of fiberboard available than MDF called HDF. HDF is rarely used in speaker cabinets, and mostly made in thicknesses with coatings that make it suitable for use as flooring. To treat the subject of different types of wood, and cabinetmaking, is a subject which can and does fill textbooks.

That said, for those of you who want to see the technical differences between MDF and HDF, here is a link that does a beautiful job of explaining it qualitatively and quantitatively all in one page: MDF vs HDF

When shopping loudspeakers, take the time to examine the construction of the cabinet or at least ask the manufacturer for some specifics such as panel thickness and what measures they used to reduce cabinet resonances. A speaker cabinet with at least 3/4" thick side panels and 1" front baffles (when mounting heavy woofers) is a good indication of rigid cabinet construction. The larger the box, the more bracing that will be needed so if you have a 5' floorstanding speaker or subwoofer with no bracing inside, and it sounds hollow when you tap on the side panel, chances are the corresponding bass it produces will be highly colored and boomy since the cabinet panel resonance will be low enough in frequency to be within the woofers usable bandwidth of operation. We at Audioholics have seen floorstanding speakers from Europe that had no bracing whatsoever but instead included a tiny compartment on the bottom of the cabinet to add lead shot or sand. While this does help to plant the speaker to the floor, it doesn't significantly reduce panel resonances nearly as effective as a properly braced cabinet but it does save on shipping costs since the unbraced cabinet will weigh significantly less and cost less to produce.

Editorial Note by Philip Bamberg

MDF is chosen mainly because it routes nicely, and its homogeneous nature also makes its sonic characteristics more predictable. Very expensive speaker cabinets are being made from aluminum carbon fiber so customers really concerned about stiffness to weight ratio may be better served considering options from companies offering that type of construction. It is easy enough to test any speaker for cabinet resonances. Simply play a sweep of densely spaced pure sine test tones and a moderate level and you will hear whether or not the cabinet suddenly sounds louder at certain tones.

Bottom Line: if a speaker box seems flimsy in construction and sounds hollow when you tap on its side panels, chances are they will color the overall sound quality of the speaker more so than a more inert design. Let your ears decide if they sound accurate to you or not as a result.

Myth #4: Polyester fiber fill is the best thing you can use to eliminate internal reflections and improve the sound of the speaker

Most polyester fill (those white or black fibers put inside speaker cabinets) are not the best thing to use to stuff speaker boxes. For those of you too young to remember back to the 70's, we typically used fiberglass in the cabinet to accomplish two main goals. Firstly, it absorbs mid and high frequency reflections from the back of the box, preventing them from exiting the system after a strong reflection from the inside of the box, and then again through the speaker cone, causing temporal and frequency aberrations. Secondly, fiberglass actually physically makes the box behave larger than it really is, effectively letting your woofer reach down to a lower frequency cutoff than it would without the fiberglass.

Fiberglass Insulation (left pic) ; Polyester roll (right pic)

Back in the day when the USA still had a significant manufacturing sector in the audio industry, we routinely used fiberglass to accomplish these goals. The problem with fiberglass, and the primary reason it was replaced with polyester fibers, is that it is created from short straight glass fibers (normally held together with a glue) which come free from the material and stick in your skin providing a great deal of irritation when it is handled. The loudspeaker industry’s collective solution to this was to switch to polyester fiberfill, the same material used in perhaps as many as 90% of all those hypo-allergenic pillows you find in the department store. This was a great relief to those who had to stuff boxes, and a great irritation to the few of us who actually performed side by side comparisons with real fiberglass. Having measured different varieties of polyester fiberfill (including hollow fill) and comparing it to fiberglass, the results of using most fiberfill are much closer to using nothing than they are to using fiberglass or higher density sound fill. (Yes, long haired wool is still the best, and at last check it still cost about $13 per pound.) Ironically, Owens Corning solved the problem of fiberglass irritation by creating a product some years ago where the fibers were curled, which stopped them from irritating exposed skin. Sadly, because it was slightly more expensive than the straight fiber fiberglass, despite the fact it was non-irritating to the skin, the company ceased production of this material. It is a good bet, the cheapest and fastest and most dramatic fix a consumer can make on his system would involve replacing polyester fiberfill with real fiberglass in his cabinet. To keep it in place, a slightly porous cloth (we use grille cloth) can be stapled on top of the fiberglass to prevent the escape of the material through the ports, or its entry into the internal moving parts of the loudspeaker drive units. The grille cloth is acoustically transparent so its presence does little to stop the wave from being absorbed (in part or whole) by the fiberglass.

Editorial Note by Philip Bamberg

SPL inside the box can be 140dB, so even fiberglass will not reduce the level to prevent the bad sound from emanating back out of the woofer.

Inside the constrained volume of the box we have standing waves and traveling waves. Standing waves occur at low frequencies, while traveling waves occur at higher frequencies. The transition occurs at a frequency whose wavelength equals double the distance between two walls. A good example is a tower cabinet whose large side panels have an interior spacing of 7”. Standing waves then apply for frequencies below 13500/7/2~=1000 Hz. Traveling waves are above this point. Say the 7” woofer crosses over at 2 kHz. Now there is one octave of passband traveling frequency, and another octave or two of stop-band frequency. Stuffing of any kind will help to attenuate the internal (bad) sound. But making 140dB much quieter is simply not possible through stuffing quality alone. For this reason, I would never use fiberglass!

Larger volume boxes show lower internal SPL. This is because there is a longer path to provide attenuation of traveling waves.

Stuffing the entire box volume also effectively increases the box interior volume, since the speed of sound is reduced slightly. This is akin to increasing the box volume by about 15%. This will skew the bass rolloff a little, and the designer can take this into consideration.

All my closed-box monitors are fully stuffed with poly-fil, and all my vented designs are about 80% filled, because the area near the port inlet must be unblocked. I arrived at the decision to stuff ported speakers this way after empirical measuring and listening tests.

Now here is a simple test that can be performed on any speaker with the woofer removed. We all possess a small wideband sound source, which is the sound made by snapping our fingers. Snap your fingers inside the box by reaching through the woofer hole. Listen to the sound with your ear near the hole. Do this with 100% stuffing, and with no stuffing. You can also knuckle-rap a cabinet panel and listen. The sound is much more dead with the fully stuffed configuration.

Another way to listen to the inside of a speaker is to play music or test tones at a low level, and then put your ear up to the port exit. You may be surprised at how audible and colored sounding is the midrange band. Add more stuffing to this situation and the colored sound reduces in amplitude. So there is also a myth that one can adjust the detail of their monitor speaker by adding or removing stuffing from inside the box. Never remove stuffing! If the audiophile needs something to tweak, he needs to look elsewhere. Any increase in “detail” he hears with less stuffing is truly an increase in the colored interior box sound, and not more signal detail.

Editorial Note by Jeff Symanski

Loudspeaker fill serves a number of purposes, but the more surface area that is included, the better the outcome in terms of loudspeaker performance. Polyester will inherently have less surface area than most glass fiber materials. Thus, I would probably come out on the side that glass fiber is usually the better way to go. Foam material with a surface area similar to or higher than glass fiber will also perform as well as or better.

Surface area in this context is the composite surface area formed by all the interstices in any porous material. It can also be thought of in terms of density. The denser the better as long as the material is significantly porous. Polyester is generally less dense than other porous materials, such as glass fiber and open-cell polyethylene / polyurethane foams.

The one caveat would be related to the actual surface area / density of polyester. For a more thorough analysis, I would recommend obtaining information on the specific fill materials being used. A simple comparison of their (ASTM) flow resistivity values should be sufficient. The hard part would be obtaining that sort of information from loudspeaker manufacturers.

Bottom Line: Some poly fill / dacron can be a compromise and better insulation (ie. fiberglass or high density poly fill) will improve the sound quality of your speakers. If the manufacturer is willing to spend the time and money to do it right, that is a bonus. If not you as the end user should be willing to replace the stuffing of your speakers. It is neither difficult nor expensive, and can result in an audible and measurable improvement in your sound.

Myth #5: Cabinet Shape plays a dominant role to reducing standing waves

Some believe that internal standing wave modes can be spread out by choosing box dimensions which differ by the golden ratio, or some other ideal ratio. The theory is that by spreading out the resonances more evenly in frequency, their audibility will be diminished. The reality is making a irregularly shaped cabinet does NOT eliminate standing waves, it just makes them much harder to predict. This can be seen in Dr. Floyd Toole’s book “Sound Reproduction: Loudspeakers & Rooms” via figure 13.4, p. 206. The primary difference between rooms and speaker boxes is scaling factor.

Editorial Note by Philip Bamberg

While the theory is valid, it is not practical to design speakers this way. Obviously not all customers will accept a speaker whose dimensions only come in the ratio of 1:1.6:2.6. Such a speaker does not eliminate resonances in and of panel proportions alone, so these must be addressed as previously discussed. Box shape improvements do not circumvent the 140dB internal SPL issue, either. Golden ratio theory can certainly be useful for room dimensions, though.

Bottom Line: If a manufacturer is trying to sell you on the notion that they shaped their speaker cabinet a particular way to eliminate standing waves, realize that the more likely reason is to differentiate their product in appearance from the masses or to sell a good story based on pseudo-science.

Conclusion

Loudspeaker companies will rarely give you a peek inside the box to see the quality of construction of their cabinetry. Those that don’t typically don’t want you to see for a reason; they cut costs. Instead they will downplay the importance of building a rigid cabinet in favor or mass producing them on an assembly line out of the thinnest materials with the least amount of bracing to reinforce the structure. They often then tout that as a benefit claiming lowering the cabinet resonance is a good thing when in fact the exact opposite is true. When shopping for speakers, it’s a good idea to ask the loudspeaker company of your choice some design details on how their box is constructed such as:

- Cabinet material used: particle board, MDF, HDF, Plywood, other? (run don’t walk away from particle board cabinets)

- Thickness of the baffles (at least 3/4” should be used in ALL cases)

- How is the cabinet braced? (if you’re looking at a 4ft tower with no internal bracing at all and it sound hollow when you tap on it, be weary)

- Are the drivers flush mounted (preferred) to the baffle to reduce diffraction?

- ·Are cabinet edges rounded/smoothed (preferred) or just a square box?

The cabinet is a big expense in the total budget of a loudspeaker and an easy area for manufacturers to skimp on and directly affect performance if not done right. Take the time to research the mechanics of the enclosure if the manufacturer is willing to espouse the information. Pay close attention to our reviews where we often dissect the speakers to give an inside look and analysis. If you are seeking out truly high quality loudspeakers, don’t settle for mediocre or even average build quality, especially if the price tag doesn’t justify it.

Acknowledgements

I would like to personally thank the following people for their contributions and/or peer review of this article, all of whom are true experts in their respective fields. Their contributions enabled us to make the most comprehensive and accurate article possible on the very complex topic of loudspeakers cabinets dealt with herein.

- Paul Apollonio, CEO of Procondev, Inc

- Philip Bamberg of Bamberg Audio

- Jeff D. Szymanski, PE & Acoustical Engineer

- Steve Feinstein, Director of Marketing & Product Development for Atlantic Technolgy

- Shane Rich, Technical Director of RBH Sound

- Dr. Floyd Toole, PHD & Chief Science Officer of Harman

- Ed Mullen, Directory of Technology & Customer Relations of SV Sound

- Mark Sanfilipo, staff writer for Audioholics.com & avid loudspeaker builder