Abandon Just In Time Manufacturing to Save Audio Industry?

One of the most colorful people that I’ve ever met in the

audiophile hobby/business is named Craig Pease. He was the audiophile pioneer

who saw the market for high-end desktop audio at a time when computer monitors

were a few feet thick. That was a long, long time ago. His brand, Evett &

Shaw, was about the most extreme that I’ve ever encountered in that each and

every part had to be the single finest known to man. The rectangular, Elan,

desktop speakers were handmade in Salt Lake City, Utah with sides that included

exotic woods, colorful “polymers” (like Spinal Tap’s record label) or even

organic stone. The “plinths” that the small speakers sat on were often

hand-cut, thin chunks of polished real stone like samples that you might find

at a kitchen design boutique. The feet on the speakers put Goldmund cones to

shame. But get this… the speakers actually came packed in a Zero Halliburton

metal suitcase that you could actually use later for your next Miami Vice-style

future drug deals. That was a lot of insight, creativity, performance and value

for a $2,200 per pair desktop speaker – especially back in that era.

One of the most colorful people that I’ve ever met in the

audiophile hobby/business is named Craig Pease. He was the audiophile pioneer

who saw the market for high-end desktop audio at a time when computer monitors

were a few feet thick. That was a long, long time ago. His brand, Evett &

Shaw, was about the most extreme that I’ve ever encountered in that each and

every part had to be the single finest known to man. The rectangular, Elan,

desktop speakers were handmade in Salt Lake City, Utah with sides that included

exotic woods, colorful “polymers” (like Spinal Tap’s record label) or even

organic stone. The “plinths” that the small speakers sat on were often

hand-cut, thin chunks of polished real stone like samples that you might find

at a kitchen design boutique. The feet on the speakers put Goldmund cones to

shame. But get this… the speakers actually came packed in a Zero Halliburton

metal suitcase that you could actually use later for your next Miami Vice-style

future drug deals. That was a lot of insight, creativity, performance and value

for a $2,200 per pair desktop speaker – especially back in that era.

There was, however, an issue with Evett & Shaw and specifically their increasingly popular, Elan speakers. They were kinda hard to build. It wasn’t that the team in Utah couldn’t build them as they could and often did to bespoke specifications. The issue was having all of the over 120 parts in hand to actually be able to finish the speakers. Simply put, 20 plus years before today’s COVID-19 inspired supply chain issues – these speakers often were one out-of-stock nut or one resistor (or something) short of being able to ship. Think about the image from this past fall with all of those GM cars sitting in a parking lot in Michigan waiting for microchips. That was Evett & Shaw in the early 2000s but with speakers colored like a “Blueberry iMac” instead of electric cars but the problem remains the same.

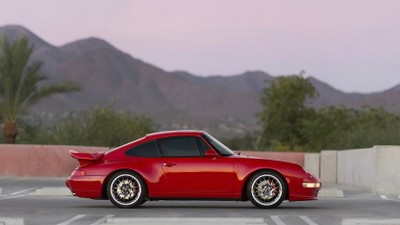

In the 1990s, every business school was enthusiastically promoting the concept

of JIT (aka: just in time) manufacturing. An excellent example of this in

practice was how Porsche turned their entire company around in the mid-1990s

from delivering one of the most flawed cars coming off the production line to

ultimately one of the most reliable car brands in the world today. Porsche

accomplished this with the help of two “retired” Japanese auto-maker CEOs

showing them how to use more modern manufacturing techniques and JIT

manufacturing to build a better car. What nobody saw coming was when demand increases,

as it has in the COVID era, that there might be severe shortages of parts

needed to make a final product. Just like it can be hard to find toilet paper,

Clorox wipes or baby formula at times. The internal parts needed to make AV

components also can be in short supply.

In the 1990s, every business school was enthusiastically promoting the concept

of JIT (aka: just in time) manufacturing. An excellent example of this in

practice was how Porsche turned their entire company around in the mid-1990s

from delivering one of the most flawed cars coming off the production line to

ultimately one of the most reliable car brands in the world today. Porsche

accomplished this with the help of two “retired” Japanese auto-maker CEOs

showing them how to use more modern manufacturing techniques and JIT

manufacturing to build a better car. What nobody saw coming was when demand increases,

as it has in the COVID era, that there might be severe shortages of parts

needed to make a final product. Just like it can be hard to find toilet paper,

Clorox wipes or baby formula at times. The internal parts needed to make AV

components also can be in short supply.

Every company that builds a physical product aims to be as efficient as possible and Just In Time manufacturing speaks to that endless goal but there are times when having finished inventory is just more important than penny pinching on parts costs. There is one recent, COVID-era success story in the performance-value loudspeaker business from a company who acted on their hunch that more people might want their speakers and subwoofers thanks to COVID so they loaded up on inventory. With transducers coming from China, like most everything else that we consume in our economy today, it takes months to make, ship and organize inventory to be able to fill orders under the best of circumstances. This AV company’s leadership decided to buck up and stock up, and what a good idea that was. While other companies are clean-out of product to sell – they are flush with speakers and subs that can ship now for your newly built AV man-cave. And they are raking in the bucks big time now.

The Audio Industry Much Needed Change

Perhaps it is time to reconsider how high end audio products are built, made, packed and sold?

Could it be time to simplify audiophile products? Could it be time to order enough parts to be more flush with manufacturing inventory so that you can always build more product? Could it be time to use more and more domestically sourced products ranging from parts to cabinets to shipping boxes, packing etc..?

It is very hard to be in business when you don’t have something to sell.

From the balcony of my house, you can see at least a dozen

container ships floating in the Pacific Ocean waiting to unload at either The

Port of Los Angeles or Long Beach – where 40 percent of all goods arrive for

consumption in this country. A lot of media hype has been made of the backup at

the ports and rightfully so. There are real-world problems with the way

truckers are paid for their time, thus many have taken their chance to be part

of “The Great Resignation” by leaving countless $100,000 per-year jobs open for

those looking for a new career. The bigger issue is that the economy has

drastically changed at the global level. Economists suggest that we’ve moved

from a 70-30 split between “services” and “products” to more of a 50-50

balance. In the most basic assessment, there are more pressures on the ports

today because there is a much larger volume of products coming into the country

for us to buy. You don’t have to dig too deeply into any of our lives to see

how we all have changed our spending habits. For me, I am trying to play The

Top 100 Golf Courses In America (Golf Magazine list 2013-14). I have 73/100 and

19 of the top 20 as of now but I haven’t played a new Top 100 in over 18

months. Hell, I haven’t been on an airplane in 23 plus months when I used to

fly 12 to 15 plus times per year. I also don’t go to NHL hockey games anymore.

I don’t really eat out unless it is outside and even that is rare. The money

that I used to spend on services and experiences is now invested more in say

kitchen appliances, a new “used” car and so on. Tangible items. I bet the same

goes for you too.

There is always room to make for a better audiophile experience but it is hard

without really fantastic AV gear. Much of the best audiophile gear is made here

in the United States but it is close to impossible to build said products

without parts/chips/etc… made in China. If you don’t have a healthy reserve of

them on hand – then good luck to you for making a living or keeping your

company going and-or growing.

There is always room to make for a better audiophile experience but it is hard

without really fantastic AV gear. Much of the best audiophile gear is made here

in the United States but it is close to impossible to build said products

without parts/chips/etc… made in China. If you don’t have a healthy reserve of

them on hand – then good luck to you for making a living or keeping your

company going and-or growing.

If the goal is to find and cultivate a new crop of audiophiles that are younger than 45-plus-year-old Gen-Xers (like me) then seeing huge increases in the price of gear is a recipe for failure. Econ 101 teaches us that if supply is low then the prices are going to be high. Take a look at used car prices for a modern example of that. Imagine a world where more audiophile components are made domestically but there is ample supply to feed a younger generation’s love for music (and hopefully higher performance audio playback gear). That would be a very happy place.