Turntables—A Short History and Explanation

Turntables are getting very popular again. People are rediscovering the romance and appeal of vinyl, plus there is the now-solidly-entrenched faction that simply believes that analog-produced music sounds better than digitally-produced music. So, this is probably a good time to take a step back and look at the history and development of the modern turntable and what the major design considerations were. There are two main types of turntables in use today—belt-drive and direct-drive—so we’ll explore how they work, what the thought is behind each one, and what the pluses and minuses are of the two types.

Drive Systems

First, a little turntable history. When stereo was first introduced in 1958—when single-channel music systems (“mono”) became 2-channel stereo systems—the most popular turntables were automatic “record changers.” These were turntables that could play several records in a row. Users would stack multiple records onto the tall central spindle and the turntable would automatically drop the next record down to the platter when the previous record was finished playing. Since a typical record contained about 20-25 minutes of music on a side, stacking four or five records was a convenient way to enjoy well over an hour of uninterrupted music.

Garrard RC-88 changer about to “drop” a record

Idler Wheel (“Rim Drive”)

Record changers needed a drive system with lot of torque in order to spin at the correct speed even when the platter was loaded down with several records. They used a high-torque drive system called an “idler wheel,” sometimes called “rim drive.”

The idler wheel was a small wheel about 1.5” in diameter inside the rim on the underside of the platter. It was driven off the main turntable motor and “geared down” to the proper record speed of 16 2/3, 33 1/3, 45 or 78 RPM.

Idler wheel was a dependable, simple, gutsy drive system. All the popular turntables used them, like the Dual 1009 and 1218, the Miracord 50H Mk II and 40A, and most of the Garrards, like the extremely popular RC-88 of 1960.

Dual 1218 idler wheel changer

They had two main downsides:

- Over time with heavy use, the idler wheel could

develop a “flat spot,” imparting a thump-thump-thump sound to the

record.

Replacing the wheel was inexpensive and fast, however. - Ported speakers were especially prone to the interference and distortion caused by these “subsonic” frequencies, which is why amplifiers and receivers in the turntable era had front panel “rumble” filters that cut the low frequencies, usually below around 60Hz. It cost you some bass, but it cleaned up the sound. Sealed speakers (“acoustic suspension”) were pretty much immune to “rumble” because their woofers were better damped, which is just one of many reasons that sealed speakers like AR, KLH and Advent were the market leaders in the 1950’s through the 1970’s.

Belt Drive

Serious audio/equipment aficionados (“audiophiles”) distained the notion of stacking and dropping records on top of each other and grinding their fragile grooves against one another. No, instead, serious audio enthusiasts were “one record at a time” users. That being the case, there was no need for the high-torque idler wheel drive system, since single-play turntables didn’t need the torque to power through the weight of all those records sitting on the platter. A single-play turntable only needed enough torque to spin one record. There must be a quieter way to do this than with a noisy idler wheel, with its mechanically-coupled rumble.

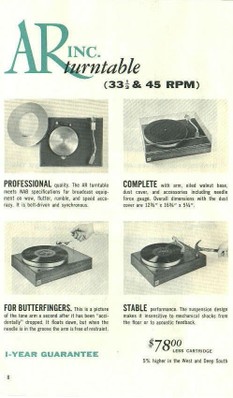

There was a better, quieter way. It was called the belt-drive turntable. In the early 1960’s AR (Acoustic Research, the people who invented the small high-performance “sealed” speakers that revolutionized the entire stereo industry) came out with a simple, inexpensive, belt-drive single-play turntable. It was simply called “The AR Turntable” and it sold in the millions. Millions. Its basic audio performance in terms of speed accuracy and absence of rumble was far superior to the standard record changers of the day.

The AR belt-drive single play turntable

The AR Turntable (and other belt-drive turntables) used a rubber belt that stretched from the turntable’s motor around a lip on the underside of the platter to spin the platter. The inherent vibration-damping trait of the rubber belt meant that these turntables had much quieter operation than most idler wheel units because the motor’s natural vibrations would simply be damped out and absorbed by the rubber belt before they reached the record. It was (and remains) a system of beautiful and inherent simplicity and efficiency.

There were two main downsides to belt-drive:

- The belts would stretch over time and slip,

resulting in inconsistent platter speed (known as “wow” and “flutter”) and

would require replacement. Replacing the belt was fast and inexpensive, however.

- The overall torque of a belt-drive system was much lower than idler wheel, which is why stacked record changers were always idler wheels—you needed that gutsy torque to spin a heavy platter laden with the weight of 4 or 5 LPs. A belt-drive system just couldn’t do it. But as we said, that didn’t matter to the serious audio enthusiast. They didn’t want to stack records.

Direct Drive

Then around 1972, Panasonic introduced a new drive system, under its Technics brand name: Direct Drive and the now-classic Technics 1200 turntable.

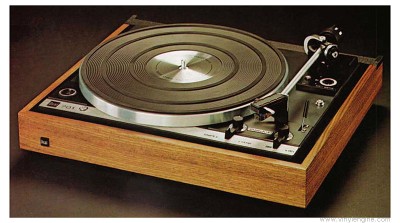

Technics 1200 direct-drive turntable

In a direct-drive turntable, the platter sits directly on the drive motor (often speed-controlled by a quartz-control system, like a fine Swiss watch), which spins at exactly 33 1/3 or 45 RPM—far slower (and therefore more quietly, with less vibration) than the motor in either a belt-drive or idler wheel system. And they were torquey too—although by the 70’s, stacking records on top of each other 1960’s-style had fallen out of favor, so there weren’t really any “direct drive” record changers.

Direct-drive didn’t require that the user replace an idler wheel or a drive belt. They were essentially maintenance free. (Maybe a drop of lubricating oil once every 6 months or year. That was it.) Their speed accuracy was great. They were quiet—although truth be told, they did still impart a little noise to the rest of the system. A minor downside was that since the platter sat directly on the motor (that’s why they call it “direct drive”) whatever small amount of noise and vibration the motor did produce went right to the platter.

Audio enthusiasts still debate the relative merits—plus and minus— of direct drive vs. belt drive. Belt-drive aficionados insist that the insulating properties of the rubber belt imbue it with superior acoustic characteristics compared to a direct drive turntable. Belt-drive supporters also say that the character of the noise that a direct-drive motor transmits to the platter is more objectionable than the noise transmitted by a belt system (having to do with the spectral content and harmonic structure of the noise signal, etc.). Direct-drive proponents argue all day long that any differences in noise are minimal and theoretical and are totally swamped by direct-drive’s real-life advantages in speed accuracy and reliability.

Tonearms

In reality, the overall superiority of one turntable over another has as much—if not more—to do with its tonearm characteristics as it does with its drive system. Straight vs. S-shaped tonearms, tracking angle distortion, tonearm mass (and compatibility with cartridges of differing compliances), pivot friction, dynamic vs. static balance systems—there are lots of things to consider.

Let’s look at these issues and give them a brief overview:

Straight vs. S-shaped

With a tonearm, one of the most important characteristics is the weight or mass of the tonearm. It stands to reason that the lower the tonearm’s mass, the better it will glide over the record’s grooves and track the slight ups and downs of the record surface (after all, no record is perfectly flat). Another design consideration is lateral balance, the notion of having equal mass distributed on either side of the tonearm’s pivot. As with most things in audio engineering, there always seems to be a tradeoff.

A straight tonearm can have the lowest mass since there is literally less material from the pivot point to the headshell. But with the offset-angle of the headshell, there is very slightly more mass to one side of the pivot point than on the other side. Theoretically, this imbalance can lead to a small amount of audible tracking distortion.

“S”-shaped tonearms, by virtue of their curved shape and their headshell being right in line with the tonearm, have equal mass to either side of the pivot point. That’s good. However, if you “straightened out” an S-shaped tonearm, it would be longer than a straight tonearm, and thus have greater mass. The classic tradeoff. Good for bad. Bad for good.

Pivot Friction

The pivot point of the tonearm should have as little friction as possible, obviously, since that friction is a major determinant of how easy and unrestricted the tonearm’s action will be as it moves across the record. Manufacturers used all manner of bearings, knife edges, pointed terminations and the like to ensure the lowest friction possible. The combination of tonearm mass and pivot friction make up a very significant portion of tonearm performance.

Balance and Tracking Force

Another important consideration for tonearm performance is the manner in which the tonearm is balanced and how the tracking force is applied. Most tonearms are balanced (to a horizontal “level,” floating in air) by turning the counterweight behind the pivot closer or farther away until the arm is free-floating perfectly level with the weight of the cartridge installed in the headshell at the other end. Once the arm is balanced, the tracking force is applied, in accordance with that particular cartridge’s tracking capability.

Ahhhh….but the way in which that tracking force is applied can actually make a surprising difference in the performance of the arm/cartridge combination. Dual had a great system: they used a coiled spring located right at the tonearm pivot point to “squeeze” the arm down with the exact amount of tracking force you wanted:

¾ gram, 1 gram, 1 ¼ gram, etc. The beauty of this method was that it was accurate in any plane, meaning even if the turntable was not sitting on a perfectly level surface, the tracking force was still accurate.

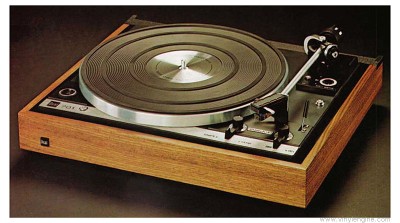

Dual 701 Belt-Drive Turntable with Coil-Spring Tracking Force System

In contrast, a gravity-type tracking force adjustment (such as using the counterweight to apply the tracking force) required that the turntable be perfectly level, since the weight was, in effect, being “pulled down by gravity” in order to be accurate. If the turntable wasn’t on a level surface the actual tracking force would vary slightly from the indicated force. Enough to be audible? Maybe, maybe not. But definitely enough to annoy an OCD audiophile.

The worst method of all for applying tracking force was the so-called “sliding weight” method. Here, after the arm was balanced, an actual small sliding weight would be moved along the tonearm towards the headshell to apply the tracking force. The farther from the pivot (closer to the headshell), the greater the tracking force. Here was the problem: As the weight was slid along the tonearm, the effective mass of the tonearm increased as the tracking force was increased. It’s akin to holding a 5-lb brick in one hand close to your body—easy. But extend your arm all the way out while holding that same brick, and it becomes impossible. That’s a perfect example of the “effective mass” being increased. The actual mass is the same—it’s the same 5-lb brick and the same person holding it. But the relative positioning makes all the difference.

Philips had a really nice manual belt-drive turntable in the early ‘70’s—the model 202—that used the sliding weight tracking force method. A serious drawback to an otherwise nice turntable.

Philips 202 Turntable: Sliding weight clearly visible mid-arm

Tracking Distortion

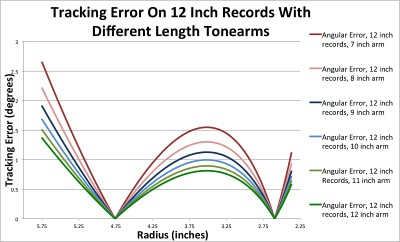

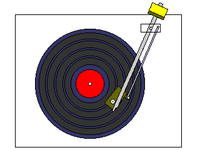

The record master (the metal “parent” that presses all the “offspring” vinyl copies) is cut with the cutter positioned at 90˚ to the centerline radius of the disc. 90˚. But you can see that with a pivoting tonearm, the playback stylus of the cartridge is never positioned at 90˚ to the grooves all across the record. The amount by which this playback tracking angle deviates from the 90˚ cutting angle is called the tracking error, and it is audible to some degree. Traditional pivoting tonearms—both straight and S-shaped—angle the headshell such that the stylus’ position relative to the record’s grooves is a “good compromise” across the entire record surface, fairly consistent from lead-in to lead-out grooves. There are two points on the record where the angle is at the desired 90˚, and over the rest of the record, it’s off. However, the tracking-angle error in a correctly-angled headshell is pretty small between those two ‘good’ spots.

Fortunately (or unfortunately, depending on how you look at it) most listeners aren’t really aware or bothered by the tracking angle distortion, because it’s relatively low in level, and even more importantly, the listener almost never actually hears a record played back without this tracking distortion for comparison. You hear an amplifier playing clean and clipped, and you can compare them. You hear a speaker bottoming out and not bottoming out, and you can compare them. But most listeners only hear records played with tracking angle distortion. They have nothing to compare it to.

In point of fact, tracking angle distortion is not that horrible a problem. As these two charts illustrate, a tracking error of as much as 5˚ only corresponds to a 2nd-harmonic distortion of less than .2%, which is very low. Still, purists will argue, it’s additional distortion, on top of amplifier and speaker distortion, so any distortion that can be eliminated is a good thing.

In consumer electronics, when there is a technical problem, engineers rush in. If the engineers are successful, the sales/marketing people rush in right after. Such was the case with tracking distortion.

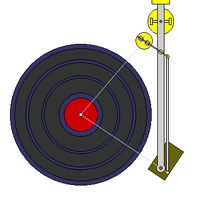

Tangential-Arm Turntables

What’s needed to eliminate tracking distortion is a turntable with a tonearm that positions the cartridge such that it plays back the record at the same 90˚ angle at which they were cut. Sounds simple and logical, but the execution is quite difficult. With a conventional pivoting tonearm, the arm moves freely, literally being “pulled” across the record by the stylus as it plays the continually diminishing spiral diameter of the record. (Now you can really see how important tonearm mass and pivot friction is, since the entire motion of the tonearm depends on how easily that tiny, fragile stylus can “pull” that comparatively huge, massive tonearm along with it).

Tangential-arm turntables have their tonearm (and thus the cartridge’s playback stylus) positioned at 90˚ to the record grooves, just like the cutting stylus was, so their tracking error is zero. Great.

But in order for the tonearm to move across the record, it’s necessary for the arm to be controlled by very precise electric motors that push the arm across the record, rather than a conventional pivoting arm which is pulled across the record by the stylus. The electric motor arrangement of the tangential-arm turntable is a very particular, complicated arrangement, fraught with oft-realized opportunities for failure. In practical terms, the degree of objectionable audibility of tracking distortion that was “solved” by a radial-arm turntable ended up being the living embodiment of that old phrase, “Too complicated by half.” In practical market terms, it just ended up not mattering one whit to the majority of users.

Nonetheless, there were some clever tangential-arm turntables that hit the market. In spite of their mechanical complexity, high cost and often-questionable reliability, when they worked, they accomplished exactly what they claimed to do: eliminate tracking error distortion. Were they a huge audible improvement over the conventional pivoting arm turntable? No. Were they expensive and finicky? Yes. But their existence deserves to be noted.

The Rabco units were pretty much the original linear-trackers on the market. Technics also had a series of models that worked quite nicely, using what was called a “P-mount” cartridge. P-mount was the industry’s attempt in the late-1970’s at simplifying cartridge mounting with a simple plug-in system that used a standardized configuration across all brands. It only enjoyed modest acceptance since audiophiles disdained the limited cartridge choices and restricted adjustments of the one-size-fits-all approach.

Rabco ST-7 Linear Tracking Turntable

The Garrard Zero-100

This turntable deserves its own in-depth write-up, considering what a singularly unique and innovative product it was. What if tracking error distortion could be eliminated inexpensively and simply with a conventional pivoting tonearm? Wouldn’t that be great? All the mechanical simplicity of a normal pivoting tonearm, no complicated electric motors, plus the audible superiority of zero tracking distortion. Now, that’s something customers would eat up.

That was the thought behind Garrard’s Zero-100 automatic turntable. Using an ingenious—but mechanically-simple—“auxiliary” arm alongside the main arm that caused the moveable headshell to continuously pivot to the correct position such that the stylus was always at the 90˚ playback angle, the Zero-100 was one of the most clever and cost-effective solutions to an existing audio problem ever devised. It worked perfectly. Aficionados swear that records played on the Zero-100 have a clarity and openness to their sound simply unavailable from ordinary pivot-arm turntables, regardless of their tonearm sophistication. The design was so well done and precisely-executed that the “auxiliary pivot arm” added virtually no effective mass or pivot friction compared to an excellent traditional tonearm.

Garrard was a first-line turntable company and, expectedly, the rest of the Zero-100’s performance was quite good. Interestingly enough, the Zero-100 was an idler-wheel-driven stacking record changer, not a higher-end belt-drive single-play design. One might think that an audiophile-oriented feature like zero tracking-angle distortion would not be of that much interest to the record-stacking crowd, but this is yet another good example of how product planning/marketing people are just regular ol’ folks like you and me. Little inexplicable errors in judgment happen in all walks of life. Apparently, turntables from 1971 are no exception.

Garrard Zero-100 Turntable

Idler-wheel-changer or not, the Zero-100 was an excellent turntable. Its basic performance—rumble, wow and flutter, speed accuracy, tonearm friction, etc.—was quite excellent and it never suffered any excessive reliability problems despite the complexity of the articulating arm. It sold well as a singular model during its roughly 4-year run, but Garrard never introduced any additional follow-up pivoting-arm models in the ensuing years, nor did any other manufacturers emulate the design in their own products. In the end, the Garrard Zero-100 turntable was the quintessential example of the dictum, “A solution in desperate search of a problem.” But it was a fascinating product, a great example of clever, cost-effective engineering that redounded convincingly to the customer’s benefit, even if that benefit was mostly theoretical.

Zero-100 perpendicular at lead-in grooves, halfway through record

Paradoxically, this entire tonearm/cartridge discussion is not as relevant as it once was, because most turntables today come with a pre-matched and -mounted cartridge, whose compliance, tip mass and tracking capabilities have been chosen to compliment the host turntable’s tonearm’s characteristics for optimum compatibility and performance. (At least, we hope so!) You can read more about the tonearm-cartridge interface in our Turntable Buying Guideline Article.

Direct Drive and the Rise of the DJ

One advantage of direct-drive is indisputable, however: The rugged, high-torque, low-maintenance qualities of direct-drive turntables made them perfect for DJ’ing and scratching effects. Without direct-drive turntables, DJ’ing would never have happened. You can’t DJ with a belt-drive Thorens TD 125 or an idler wheel Dual 1229.

Today’s direct-drive DJ turntables—like the Denon DJ Prime VL12—put a premium on user/DJ interaction in the live performance realm, rather than on ultra-refined music reproduction in a quiet living room like the audiophile turntables from 40 years ago. Where yesterday’s music listener didn’t want the turntable to exhibit any speed variance whatsoever, today’s professional DJ uses their turntable as a live performance instrument. Intentional speed variations, adjustable torque for fast musical start-up and precise “scratching” effects, a rugged cartridge/tonearm system that can stand up to the rigors of heavy-duty use under party conditions, these are all requirements of the professional DJ turntable.

Denon DJ Prime VL12 professional DJ turntable

Therefore, these days, turntables fall into three broad usage categories: The casual music listener, the “serious” audiophile music listener and the DJ. Turntables intended for each of these user groups are markedly different, with specific emphasis on the performance, convenience, adjustability and durability characteristics that are most important to their intended market. Club DJ turntables are all direct-drive with extensive speed-adjustment capabilities that enable the DJ to create a wide range of special effects, whereas music-listening/audiophile turntables are either direct- or belt-drive. The idler wheel is long gone, but at least now you have a full understanding of how and why we got to where we are today.

Turntables - Notable Historical Products

The following section is a listing—by no means complete or comprehensive—of some of the best-selling and most important turntable products since 1960.

Garrard RC-88 Changer

The Garrard RC-88, dating from around 1960, was representative of the early turntables that provided a transition from the mono era of the late 1950’s to stereo in the 1960’s. A ruggedly-built idler-wheel changer, the RC-88 and its ilk populated the majority of component stereo systems in the earliest days of stereo.

Garrard RC-88 Idler Wheel Changer

AR Turntable Belt-Drive Manual

Arguably the first “audiophile” turntable (introduced around 1962), the AR Turntable’s operational/mechanical simplicity was combined with superb basic turntable performance and an amazingly low price. Its suspended sub-chassis design—in which the platter and tonearm were independently suspended from the main base of the unit—gave the AR Turntable an astonishing freedom from vibration-induced “skipping.” Early magazine ads showed the AR Turntable’s base being struck with a hammer, while the record continued to play uninterrupted.

Early AR Turntable ad showing hammer

It added up to a legendary bestseller, deservedly so. Later incarnations added niceties like cueing control and better tonearms, but the basic virtues of great performance and outstanding value were a constant throughout its decades-long market life. A Hall-of-Fame product, to be sure.

Dual Changers 1009, 1010, 1215, 18, 19

The German-made Duals were probably the best of the mass-market idler-wheel changers in the mid-60’s through early 70’s. Along with good basic turntable performance (low rumble and wow & flutter, solid speed accuracy) and good reliability, the Duals—especially the 12xx series—had by far the best tonearms of the mass-market turntables. Straight, low-mass designs with double-gimbaled suspensions and gravity-independent coil-spring tracking force application, the Duals could accommodate the very best, most compliant, highest-performing cartridges available. A good Dual with a top cartridge made for a superb record-playing system at a very reasonable price.

Dual 1219 Idler Wheel Changer

Miracord 50H MkII Changer

Dual’s biggest German changer competitor during the 60’s-70’s timeframe, the Miracords couldn’t match the Dual’s tonearm performance but the Miracords set the standard for simple, smooth, operation in the classic exact Germanic manner. With the tactilely-satisfying click of one-button actuation choosing both ‘play’ and record-size at the same time, the Miracords exuded class and precision. The top-of-the-line 50H Mk II even had a disc brake (!) on the platter that brought it to a smooth stop at the end of play, accompanied by a reassuring “swishhhhh” sound as the brake engaged. The entire turntable seemed like a precision surgical instrument.

Miracord 50H MkII Idler Wheel Changer

Linn Sondek LP12 Belt-Drive Manual

Linn’s fabulously-successful LP12 is a true audio classic. A simple manual turntable in the mold of the AR Turntable, the Linn had a superior tonearm and more sophisticated looks, at a slightly higher price than the AR. The Linn had a similar suspended sub-chassis design for superb isolation, and it quickly became a cult favorite due to its ability to be easily modified and upgraded with custom parts and tonearms. The LP12 has remained a favorite of vinyl enthusiasts for several decades.

Linn Sondek LP12

Thorens TD 125 Belt-Drive Manual

This was the Swiss-German firm’s step-up from their TD 150, which was a competitor to the LP12. Adding such refinements as electronic speed control, an excellent factory-supplied tonearm and a beefier chassis for improved feedback resistance (although still using an isolated sub-chassis design), the belt-drive TD 125 was one of the most highly-regarded turntables of its day. One of its most popular attributes was the ability to order it with a blank tonearm plate and fit it with the tonearm of your choice. Its superb construction and clean, modern looks give the TD 125 a timeless quality, one that holds up quite well even today.

Thorens TD 125 w SME tonearm

SME 3009 Tonearm

By far the most popular and well-known separately-available tonearm for “component” turntables, the SME 3009 was in production in various guises from 1959 through 2004, a truly remarkable run, unmatched by virtually any other product in audio history.

It was always representative of the best tonearm performance available. Its “hanging weight” anti-skating device was incredibly visually-distinctive, and it imparted a sense of sophistication and mystery to non-audiophiles (“Ooooo…I don’t understand what that is, but it must be good!”) that surpassed virtually any component in the Hi-Fi realm

SME 3009 tonearm

Pioneer PL-12D Belt-Drive Manual

The PL-12D was not a high-end turntable. It heralded in no new era in vinyl reproduction. It was not a performance leader, nor did it introduce any notable technology or innovative features to the record-playing universe. What it did do was sell. In huge numbers. Unlike the AR turntable, which was truly manual, requiring a steady hand as the user placed the tonearm down on the record and lifted it at the end, the PL-12D had a cueing control so that no hand placement of the tonearm was required.

As such, it was the perfect college-kid turntable for the 1970’s. You could find the PL-12D in countless smoke-filled college dorm rooms (don’t ask what kind of smoke!), in systems with Sherwood, Pioneer and Kenwood receivers, driving Large Advents or EPI 100’s or AR-2ax’s as they cranked out The Allman Brothers, Emerson, Lake & Palmer and Santana at high volume on campuses from coast to coast. Reliable, decent-performing and extremely affordable, it was the ideal college ‘table.

Pioneer PL-12D

Technics 1200 Direct-Drive Single-Play Automatic

As previously detailed, the Technics 1200 started the era of the direct-drive turntable and so the 1200 takes its justly-deserved place in the turntable all-star lineup. A spirited rivalry developed in the mid-70’s when Dual came out with its higher-end automatic belt-drive single play units like the 701 and 721. The Duals clearly had slightly superior tonearms, but the Technics units had the panache of the new direct-drive technology. Various manufacturers lined up behind belt or direct and both systems co-existed the whole time, as they continue to do today.

Technics 1200 direct-drive turntable

Cartridges

No discussion of turntables would be complete without a commensurate mention of cartridges, since the buggy without the horse is of no use whatsoever. What follows is a 20,000-ft view of some of the more popular cartridges that accompanied many of the turntables we’ve talked about here. Again, this is nowhere near a comprehensive list, merely a quick look at some of the more prominent players. Perhaps we’ll delve into this a greater length in the future.

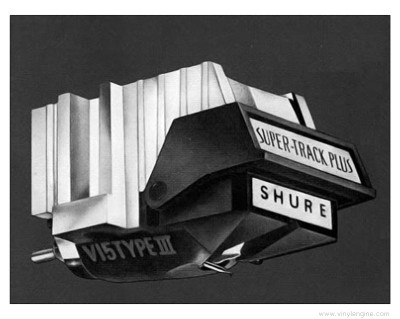

Shure V15 Series (Type II Improved through Type V MR)

The biggest-selling cartridge brand, Shure’s top-of-the-line V15 series was the reference standard for cartridges for many people all throughout the 1970’s. They became known for their ability to track “hotly-recorded” records with very low distortion, to the point that Shure even invented a new specification called “Trackability” to show how high a recorded level their cartridges could successfully negotiate without mistracking.

Shure V15 Type III

Stanton 681 EE/EEE

Shure’s big competitor during the 1970’s timeframe, many customers and critics felt that the Stantons were more musical than the Shures and Stanton also enjoyed great success and very strong sales and were immediately recognizable by their “dust brush” fitting in front of the stylus.

Stanton 681 Series

Pickering XV15 Series

Pickering sort of rounded out the “Big Three” of cartridge brands from the 60’s and 70’s. They were known as detailed-sounding units with a reputation for a slightly peaky, exaggerated high end. (Walter Stanton originally worked for Norman Pickering before leaving and founding Stanton Magnetics in 1946.) Like the Stanton 681, the Pickerings also had the “dust brush” appendage in front of the stylus.

Pickering XV15 Ad from 1960’s

Ortofon Moving Coil Cartridges

As we know, the back end of the stylus cantilever in a conventional magnetic cartridge is free-moving. As the diamond stylus moves back and forth in the record groove, the back end of the stylus is also moving freely. Imagine you’re holding a pencil between your thumb and forefinger. (Go ahead—pick up a pencil and hold it in the middle.) As you move the pointed end of the pencil (the diamond stylus in the record groove), the eraser end moves correspondingly. A magnetic cartridge works like that.

However, a magnetic cartridge doesn’t have an eraser on the back end like a pencil. It has a little magnet. The inside of the cartridge body has small wire coils. As the stylus moves, the magnet moves closer to and farther away from those coils. When a magnet is moved in relational proximity to a coil, an electrical signal is generated. (That’s why it’s called a magnetic or moving magnet cartridge.) This starts the signal playback process—the signal goes through the turntable’s wiring, into the music system’s phono pre-amp (where the RIAA phono equalization is applied), then to the pre-amp (where gain [“volume’], bass and treble, etc. are applied), then to the power amp and out to the speakers.

But…remember that analogy we used before about a 5-lb. brick being held close to your body and what it feels like when you extend your arm and try to hold that same 5-lb. brick?

That’s the thought behind a moving-coil vs. a moving magnet cartridge. A magnet at the end of that cantilever is like holding a brick with your arm extended. It really increases the effective mass of the stylus cantilever, which adversely affects the stylus’ ability to track the record groove accurately. Why not reverse the arrangement of the magnet and the coils? Put the lightweight coil on the end of the cantilever and fix the heavy magnets inside the cartridge body. That’ll really reduce the effective mass of the cantilever and thus greatly increase the ability of the diamond stylus to dance on light, precise toes around the intricate grooves of the record.

That’s the rationale of the design of a moving-coil cartridge. The problem with moving coils is that their output voltage is very low, much lower than a moving magnet cartridge. In fact, a moving coil cartridge requires a pre pre-amp, an additional circuit just to step the voltage up to the level that the regular phono pre-amp will recognize. That’s the big drawback—few pre-amps had the moving-coil pre-pre-amp built in, and so the user would have to get a small outboard pre-pre-amp circuit, at additional expense, and with the possibility of the cascading circuits adding noise and distortion. It was a hassle and just not worth it to most people.

Ortofon offered both moving-magnet and moving-coil cartridges and both types earned considerable praise for their sophisticated performance. But properly set up, supporters of the moving-coil approach swear that no other phono cartridge sounds as lifelike, transparent and three-dimensional.

Ortofon moving coil cartridge

Conclusion

So, there you have it—an overview of the basic turntable types with an historical chronology, some operational details, a look at a few of the more famous models through the years and a brief look at some of the cartridges that went with them.

Tell us what you remember from those good old days and what your favorites were—and still are!

Vinyl vs CD: Which Sounds Better?

Are you in the digital or analog camp for best audio playback? Check out our YouTube video discussion on this still controversial topic that always seems to generate a lively and often heated discussion. Can't we all just get along?!?