Coronavirus COVID-19: Will it Tank the Audio Industry?

The emergence of a highly contagious and unusually deadly coronavirus strain known as COVID-19 has dominated the news as of lately. You can’t open a newspaper, read a news app, or turn on the television without some reference to this disease. More than 100,000 people are infected with this virus worldwide. 1000’s have died. The death rate seems many times higher than typical for the flu. The Chinese economy wasn’t just slowed but completely paused for weeks to contain the virus and stem the destruction. While all this unfolded, we in America stood by and watched, waiting for it to come to our shores, wondering what it would do to us. Is our public healthcare system ready? Do we have enough supplies to manage the virus? Would we see a horrific repeat of the Spanish Flu pandemic?

Editorial Note: Coronavirus hits Audioholics

Gene DellaSala, President of Audioholics, recently found out he was exposed to the coronavirus COVID-19 from an industry person who failed to disclose he was in China prior to his visit on February 29th. It wasn't until a week after his illness and not getting better did Gene get a call regarding the infectious individual and his wife were hospitalized after testing positive for COVID-19. Gene tested positive and now he and his family are quarantined for the next 2 weeks until the health department clears his health. This is no joke and according to Gene, the symptoms range from mild to severe depending on time of day and whether he keeps up with Tylenol to control the fever and his breathing treatments to reduce the tightness in his chest.

While all these questions and concerns are of great importance, I couldn’t help but look at this and think, but what of my beloved electronics? What will happen to our industry? I was shocked to see the devastating impact that this virus, in China, was having on American electronics companies. Yet, when I stood back and examined the facts, I realized that in a modern global society, this all made perfect sense. The impact that COVID-19 is having on the consumer electronics industry is just beginning, and likely many don’t fully grasp just how big this is. This virus will likely continue to have serious ramifications for the future availability of consumer electronics. Aspects of our industry are not doing well, sales are down from prior highs, people don’t build home theaters or buy large speakers like they used to. Events like this can be the death knell to these industries, often hitting some of our favorite brands the hardest. As one source noted, we are living out a real-life enactment of a horror film right now. I’ve seen this film; it doesn’t end well.

COVID-19

Before getting into t he impact that the COVID-19 Coronavirus is having on the electronics industry, let’s talk a little about what it is.

he impact that the COVID-19 Coronavirus is having on the electronics industry, let’s talk a little about what it is.

Sadly, there is a lot of misinformation in the news, some of it planted by foreign countries to sew discord and undermine American confidence in our response. This is an important consideration. American confidence is going to tie into future problems our industry may face.

COVID-19 is the correct name for a novel form of the coronavirus that originated in Wuhan China.

It is believed that the COVID-19 virus jumped from animal to human and may be related to the trade of wild animals as food sources in Wuhan markets. Many have noted that coronaviruses are not new. This is true, in fact, two of the more serious epidemics in the past (SARS and MERS) are themselves forms of coronavirus. Both were fairly contagious, unusually deadly for certain at-risk populations, and difficult to treat. In fact, it is worth noting, we generally cannot cure or readily treat viral infections. If you get the flu or a cold, we don’t really have medicine to make you better. It isn’t like bacterial infections, where we can give antibiotics that aid the body in fighting the infection and healing.

The old adage in my family was two Tylenol, some chicken soup, and rest were the best medicine. That still holds true, even for these Coronavirus infections.

There isn’t a lot we can do aside from rest, fluids, and time.

Another interesting aspect of this virus is that it is highly contagious; many times more contagious than the flu or a common cold. Common strains of influenza have an R0 value of around 1.2 or so.

COVID-19’s exact R0 value (A value indicating how many people will be infected for every individual that already has the disease) is estimated at between 3 and 5. That number is subject to change as more widespread testing becomes available. That’s another problem. We are not testing enough people to know how contagious this really is. But that is actually good news in a way. What we are learning is that COVID-19 is, in most cases, fairly harmless. For most people, especially younger people (even babies!), the infections tend to be either limited or asymptomatic. That means that most people who get this won’t even know they are sick. Instead, what we are seeing is unusually high rates of pneumonia among individuals with compromised immune symptoms and those older than 60. It has been suggested that the death rate might actually be on par with or below that of the Flu, the main problem is how readily it spreads.

It should go without saying, but bears repeating anyway, WASH YOUR HANDS! One thing I can say, as someone who has worked in the public health sector, is that we don’t wash our hands enough, and those of us who do, don’t do it properly, and we are all making this problem worse (Curtis, 2014).

This begs the question, if the virus isn’t all that deadly, essentially a kind of cold virus, then how can it be so bad for electronics? In fact, what could a cold virus possibly have to do with the supply of consumer electronics at all? It seems like this must be more panic than reality, right? Panic itself is a huge problem, but the immediate problem goes far beyond consumer sentiment. To understand why everyone is panicking, even health officials, let’s remember the last time the United States faced a major viral epidemic.

History of Pandemics: Spanish Flu

Following World War 1 there was an emergence of a no vel strain of influenza that appeared to have an unusually deadly effect. The virus originally spread in the trenches, brought about as a result of the conditions and close quarters found there. It spread at a high rate and was unusual in that it was highly deadly to young healthy individuals. Not just young babies or older adults, but virile soldiers were being impacted too.

vel strain of influenza that appeared to have an unusually deadly effect. The virus originally spread in the trenches, brought about as a result of the conditions and close quarters found there. It spread at a high rate and was unusual in that it was highly deadly to young healthy individuals. Not just young babies or older adults, but virile soldiers were being impacted too.

How bad was the Spanish Flu of 1918?

More than 500 million people worldwide were infected, and it killed somewhere between 20 million to 50 million people.

You may be asking, "Why we are comparing COVID-19 to the Spanish Flu of 1918 rather than something like the Swine Flu, Avian Flu, SARS, or MERS?". The answer is simple, The Spanish Flu was the last true pandemic that seriously impacted the United States. These other Flu epidemics did not have the global reach that we are starting to see with COVID-19. The R0 value for the Spanish Flu is estimated to be around 2, a value that is slightly lower than the current estimated infection rate of COVID-19. The R0 values for these other viruses have typically been closer to 1.3 to 1.8. The concern is that COVID-19, while not nearly as deadly as the Spanish Flu, appears to be more contagious than much of what we have seen in over 100 years. A virus this contagious and this impactful on our daily lives will inevitably have a serious impact on our economy.

Current impact on Economy in China

I don’t want readers to think that I care more  about the all mighty dollar than I do about people’s health and well-being. I’m not writing this article to make light of the seriousness of this illness. Further, I disagree with policies that would put health at risk to save the economy.

about the all mighty dollar than I do about people’s health and well-being. I’m not writing this article to make light of the seriousness of this illness. Further, I disagree with policies that would put health at risk to save the economy.

We should put people first and accept the impact on the economy. This article is about understanding how something as tangential as a health crisis can have such an outsized role in a global economy. I will leave actual discussions of health and medicine to the experts.

Those wh o work in the financial world or economics will certainly be familiar with leading and lagging indicators. Put simply, lagging indicators are those numbers that show what has already happened. They indicate the health of our economy as it was in the past. They tend to be more accurate, but unfortunately, once we see bad news, it’s far too late. Leading indicators are measures that happen before major economic events happen; they are predictive. Inevitably we are not good at predicting the future, so leading indicators don’t always accurately predict what will happen, but they are more valuable in trying to see what is happening and develop policies and practices to stem the problems.

o work in the financial world or economics will certainly be familiar with leading and lagging indicators. Put simply, lagging indicators are those numbers that show what has already happened. They indicate the health of our economy as it was in the past. They tend to be more accurate, but unfortunately, once we see bad news, it’s far too late. Leading indicators are measures that happen before major economic events happen; they are predictive. Inevitably we are not good at predicting the future, so leading indicators don’t always accurately predict what will happen, but they are more valuable in trying to see what is happening and develop policies and practices to stem the problems.

When it comes to the impact of COVID-19, the best leading indicators we have for the American economy is to look at the devastation that already took place in China. Don’t get me wrong, we know that what is going on in China likely will not happen in the United States. If nothing else, we don’t have anywhere near the manufacturing capacity and a lot of service sector jobs, the heart of the American Economy, can be done from home (It is worth noting that some I talked with disagreed with this view and suggested that service sector jobs, as a whole, are mostly done in person and as such the American economy might be at greater risk than China’s).

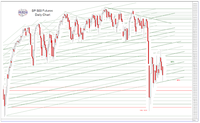

The S&P 500 has already fallen more than 11% as a direct result of COVID-19. It’s largely investor fears of what is to come. As a point of comparison, SARS only impacted 8000 people in total, killed far less than COVID-19, yet cost the economy a massive 50 billion dollars.

MERS impacted just a few hundred people yet cost the economy an estimated 8.5 billion dollars. We are dealing with well over 100,000 individuals sick, more than 3500 dead so far, a number that is rapidly increasing, so it’s easy to see why the stock market is spooked. Chinese manufacturing was forced to completely shut down for weeks to help contain the virus. It’s believed the effort probably worked, at least to some extent, but it means no goods were being produced by the world’s largest manufacturing economy. During the month of February, the Manufacturing Purchasing managers index went from a bit over 50% down to a staggering 35.7%.

This value typically does not change month to month very much, so this drop is highly unusual.

At this point, we are hearing reports that Chinese manufacturing is getting back to normal with as much as 75.8% of the workforce back to normal operations. We don’t have the current numbers for March as the month has only just started, but we asked many manufacturers of consumer electronics to tell us what they are hearing from their factories. The numbers we heard were not nearly as good as what we see from some news reports, closer to 50%. Further, what we learned suggests that manufacturing numbers alone do not tell the story of how this is impacting consumer electronics.

The Consumer Electronics Industry

To write this article I reached out to nearly all my contacts in the consumer electronics industry. Many will likely read this article and recognize the statements I am about to make.

I reached out to nearly all my contacts in the consumer electronics industry. Many will likely read this article and recognize the statements I am about to make.

As our readers can imagine, nobody likes to air their dirty laundry and nearly everyone I reached out to asked not to go on the record. The one thing I heard consistently is that the manufacturing shutdown caused by COVID-19 has been devastating. However, the impact really surprised me. It should be obvious to anyone that a shutting down of manufacturing in China would cause a serious global supply chain shortage. As one manufacturer told me, it only takes one missing part to hold up an entire product, and right now they have a lot of missing parts. The good news is we heard many of the larger manufacturers speak optimistically about the future. They are doing their best to restock supplies in Europe and the United States, gaining priority manufacturing space for their products, and expect to be mostly back to normal in the coming months. However, with big unknowns about consumer confidence, the high expense this has caused already, and the pressure this is putting on small manufacturers (many of them American), there might be bigger problems in the future.

Let’s start with supply chain constraints. The most immediate impact that COVID-19 had on the supply chain was on finished goods. Many manufacturers buy parts needed to manufacture goods on an as-needed basis known as Just in Time. It reduces waste, so you only buy enough parts for the products you need to build in that given period. For large companies like Sound United, their factories likely have enough parts to build a months’ worth of electronics. The immediate effect then is not necessarily a parts shortage, but a finished product shortage. As supplies are depleted in the United States, these companies become unable to restock quickly.

with supply chain constraints. The most immediate impact that COVID-19 had on the supply chain was on finished goods. Many manufacturers buy parts needed to manufacture goods on an as-needed basis known as Just in Time. It reduces waste, so you only buy enough parts for the products you need to build in that given period. For large companies like Sound United, their factories likely have enough parts to build a months’ worth of electronics. The immediate effect then is not necessarily a parts shortage, but a finished product shortage. As supplies are depleted in the United States, these companies become unable to restock quickly.

I was told by Paul Wilkie of Sound United that manufacturing is back up for most of their suppliers, but the workforce is still limited to about 50%. I heard similar numbers from other companies I contacted. They are flying products in, instead of using boats, to help bring supply stock back quickly.

This reduces the obvious impact on the consumer but increases costs. Make no mistakes, this alone is costing companies a lot of money. Not everyone can afford to do what Sound United is doing. Despite Sound United is overcoming this supply problem, they still had to go dark on advertising for the entire month of March which affects not only our bottom line, but any of the competing AV magazines that are also partnered and rely on advertising income to survive.

There is another looming s upply chain problem. The actual parts. These, too, are not being manufactured at the rate they were and as a result, there is a significant shortage. Companies like Apple, Amazon, Samsung, LG, Sony, and to some extent Sound United will have priority manufacturing of these supplies. Paul Wilkie of Sound United indicated that due to their decades long relationship with the supply base, they expect to get first priority on new production capacity. To reduce the impact on their bottom line they will do what they need to do to replenish parts stock and ensure the manufacturing of products are not impacted. They will be anyway, there is simply nothing we can do, but for them, the impact will be relatively small. What about smaller companies who simply can’t compete with the big companies? Well, they won’t be able to buy parts and as a result, won’t be able to build products. As their inventory is depleted, it will be far more difficult to replenish stock, and of course, the worst-case scenario is that they have no products to sell, no money coming in, and simply go out of business. How likely is this? We don’t know, only time will tell.

upply chain problem. The actual parts. These, too, are not being manufactured at the rate they were and as a result, there is a significant shortage. Companies like Apple, Amazon, Samsung, LG, Sony, and to some extent Sound United will have priority manufacturing of these supplies. Paul Wilkie of Sound United indicated that due to their decades long relationship with the supply base, they expect to get first priority on new production capacity. To reduce the impact on their bottom line they will do what they need to do to replenish parts stock and ensure the manufacturing of products are not impacted. They will be anyway, there is simply nothing we can do, but for them, the impact will be relatively small. What about smaller companies who simply can’t compete with the big companies? Well, they won’t be able to buy parts and as a result, won’t be able to build products. As their inventory is depleted, it will be far more difficult to replenish stock, and of course, the worst-case scenario is that they have no products to sell, no money coming in, and simply go out of business. How likely is this? We don’t know, only time will tell.

Earlier I referenced manufacturing time, and this is another aspect of the problem I had not considered when researching this article. It turns out that there are a limited number of factories that can build certain consumer electronics. Companies big and small tend to use the same factories, buying up a percentage of their available manufacturing capacity. Whereas Apple might buy up 90%, a small company might buy up just 1%.

What happens then when suddenly that factory is only at 50% capacity? The answer is simple, 100% of it will go to a company like Apple, none of it will go to the small companies. Not only can these smaller companies not get parts, but they also can’t get their products built.

I asked several manufacturers about moving manufacturing.

Inevitably some will say, "Can’t we move this to Vietnam, India, Mexico, or even back to America?". The simple answer is that every company I talked to said it doesn’t work that way. What we have heard time and time again is that China has perfected the manufacturing of high-quality consumer electronics. They have mastered efficiency, supply chain integration, logistics, you name it. Moving manufacturing is impossible. It takes years to move and often introduces cost increases that are untenable. Some have noted that the tariffs already lead to the moving of manufacturing to lower tariff countries where it made financial sense or was possible. All the manufacturing that stayed in China did so because it had to. At least in the short term, the direct effect of COVID-19 will not be bringing consumer electronic manufacturing back home. Many are probably also asking about how this is impacting American Made consumer electronics. The answer is simple, they are not immune, not by a long shot. Most electronic parts still come from China and many American made electronics utilize modules or boards manufactured in China. These will all be in short supply. Further, the majority of American made consumer electronics companies are the smallest in the industry, meaning they won’t be prioritized. I worry for these companies because many of them are my favorites, making some of the best products money can buy.

Inevitably some will say, "Can’t we move this to Vietnam, India, Mexico, or even back to America?". The simple answer is that every company I talked to said it doesn’t work that way. What we have heard time and time again is that China has perfected the manufacturing of high-quality consumer electronics. They have mastered efficiency, supply chain integration, logistics, you name it. Moving manufacturing is impossible. It takes years to move and often introduces cost increases that are untenable. Some have noted that the tariffs already lead to the moving of manufacturing to lower tariff countries where it made financial sense or was possible. All the manufacturing that stayed in China did so because it had to. At least in the short term, the direct effect of COVID-19 will not be bringing consumer electronic manufacturing back home. Many are probably also asking about how this is impacting American Made consumer electronics. The answer is simple, they are not immune, not by a long shot. Most electronic parts still come from China and many American made electronics utilize modules or boards manufactured in China. These will all be in short supply. Further, the majority of American made consumer electronics companies are the smallest in the industry, meaning they won’t be prioritized. I worry for these companies because many of them are my favorites, making some of the best products money can buy.

All of this only really deals with the immediate impacts.

All these pro blems will resolve in the next three to six months. It’s unlikely that these manufacturing constraints will last very long. The workforce will come back in full eventually, parts will be replenished, and stock will fill back up. I asked many of my contacts about long term effects, and all anyone could do was speculate. Nobody is quite sure, and that makes sense. As I noted earlier, the scale of this epidemic is far greater than any we have faced in modern history, and the closest proxies we have were both a long time ago and very devastating. I speculate that this will impact smaller brands the most, it is inevitable, and it may force many of them to consider alternative suppliers. It’s unclear if such alternatives exist.

blems will resolve in the next three to six months. It’s unlikely that these manufacturing constraints will last very long. The workforce will come back in full eventually, parts will be replenished, and stock will fill back up. I asked many of my contacts about long term effects, and all anyone could do was speculate. Nobody is quite sure, and that makes sense. As I noted earlier, the scale of this epidemic is far greater than any we have faced in modern history, and the closest proxies we have were both a long time ago and very devastating. I speculate that this will impact smaller brands the most, it is inevitable, and it may force many of them to consider alternative suppliers. It’s unclear if such alternatives exist.

Major companies will likely continue as usual, but I suspect the problems this will create are going to be delayed product launches and possibly the early retirement of some current products.

Parts shortages may make it impossible to continue manufacturing existing goods. Certain products are advancing technologically so fast that by the time they restart production, they will be too old. Smaller consumer electronics companies may struggle to launch new products on time. Some have speculated that this could lead to a cancellation of CEDIA Expo, or if CEDIA Expo goes on, those small companies couldn’t get products built in time for the event.

This could be a serious problem for these companies. Without CEDIA Expo , they won’t be able to launch new products or find new buyers. Apple, Google, Samsung, Sony, and LG can afford their own private launch events, for the rest of the industry, events like CEDIA Expo are critical. Sadly, I expect to see ripple effects from this event for years to come. Those businesses barely surviving as is probably won’t make it. Those doing well will survive but may look a bit different coming out of this. We often consider this a good thing, sick businesses hurt the economy. However, many of these brands may be beloved brands we love, brands we grew up around.

There is another major problem facing the industry in the coming months and maybe years. We hear messages from some folks telling us not to cancel public events, not to stay home from work, that this is all a big over-reaction.

I think the reason why is clear: There is a huge economic downside on the horizon. It isn’t just problems with manufacturing, something that likely will have a minimal effect on the American economy. This will bring out reduced earnings and wages for workers, greater perceived economic uncertainty, and a more negative outlook. That all leads to dramatically reduced consumer spending. People will stop going to the movies, they will put off vacations, they will avoid purchasing large or expensive electronics. This will do hundreds of billions of dollars in damages. We are already seeing this concern being priced into the stock market. Major companies like Apple are warning of major hits to their earnings. Negative consumer sentiment does not turn around overnight, this effect will be the most drawn out.

To wrap up the effects on the economy, I believe that we will see three main problems that play out over different periods of time. First, we will see an immediate strain on finished product supply. As China manufacturing ramps back up stocks will be replenished, but in the meantime, some electronics will be hard to obtain.

To minimize this effect larger companies will spend considerably more to bring goods to market, which may impact the ability to discount and certainly will impact the bottom line for manufacturers.

The second will be a parts shortage. This shortage will slow down the manufacture of new goods past current periods for which parts have been obtained. This will impact smaller companies more than larger companies as they won’t be able to compete with the larger companies for the limited stock of parts. All home audio companies are small compared to a company like Apple and won’t be able to compete, but companies like Sound United or Yamaha will likely fair a lot better. Whereas the first problem will likely resolve itself within a few months, this will likely last for 6 months to a year. The longest-term effect, which we are only just starting to see evidence of, is consumer sentiment. The first two clearly fall into supply-side stress. This third category is an example of demand-side economic stress.

Demand will go down for consumer electronics as consumers worry about what impact this all will have on the economic future. Many have been waiting for the other shoe to drop, about the economy, assuming we have been in a bull market far too long. True or not matters little, this is human behavior, and people will likely over-react by withholding big purchases. All of this will strain the consumer electronics industry, and sadly, likely impact small audio companies the most.

Many of you may be wond ering how this will be directly experienced by you. It varies quite a bit, and for many, buying new consumer electronics is unimportant right now. Having products out of stock, products delayed, this won’t be something you notice.

ering how this will be directly experienced by you. It varies quite a bit, and for many, buying new consumer electronics is unimportant right now. Having products out of stock, products delayed, this won’t be something you notice.

While writing this article I was in the market for a new Panasonic UHD player and found the model I wanted was out of stock nationwide. COVID-19 was responsible. Panasonic was left with stock on hand or in stores that quickly sold out. I was told that more are coming soon. How soon?

Nobody could give me a firm answer, and a few days later they were back in stock. I wanted to buy some new video lights, they are typically made in China.

Many of the models I wanted were out of stock. More coming soon, but how soon? Nobody could give me an answer to that either. While writing this article I was closely monitoring AXPONA. I had been in touch with the event staff as I have a masterclass and was asked to MC an after-party. Out of an abundance of caution they have now rescheduled the event from April to August due to coronavirus concerns.

AXPONA has recently emerged as one of the largest premier audio events and is a prime event for launching new products. As CES has lost its importance in the audio industry and with CEDIA Expo catering more to custom install, AXPONA is an important event for mid to high fidelity product introductions. This is primarily how we will experience the effects of COVID-19 on our every day lives, at least concerning home media and consumer electronics. Things we may want to buy may not be available for undetermined amounts of time and new products may be delayed. I would also guess that some of the more ambitious projects some manufacturers may take on will be delayed or even abandoned. That happens a lot. The number of new product introductions I see that never materialize is extreme and events like this often kill off many a cool idea.

Conclusion

In this arti cle, I’ve laid out a case for how COVID-19 Coronavirus is, in certain critical ways, unlike any epidemic anyone alive has experienced. The virus is spreading faster than most past coronaviruses, killing far more people, and putting our public health systems to the test. While I don’t see any evidence that this is going to be like the Spanish Flu, lessons from that event tell us that this can be really devastating to society. Necessary side effects of a viral epidemic like this create a massive downturn in the economy and it comes from both the supply and demand side. I worry that this will last far longer than the epidemic itself and likely be the most widely experienced legacy left at the end of COVID-19.

cle, I’ve laid out a case for how COVID-19 Coronavirus is, in certain critical ways, unlike any epidemic anyone alive has experienced. The virus is spreading faster than most past coronaviruses, killing far more people, and putting our public health systems to the test. While I don’t see any evidence that this is going to be like the Spanish Flu, lessons from that event tell us that this can be really devastating to society. Necessary side effects of a viral epidemic like this create a massive downturn in the economy and it comes from both the supply and demand side. I worry that this will last far longer than the epidemic itself and likely be the most widely experienced legacy left at the end of COVID-19.

While the loss of life is horrific and far worst than any inconveniences we feel around electronics, the negative impact on the economy is something that will be felt by nearly everyone on earth.

My biggest worry for our industry is that it will be too much for some of my favorite brands, and my greatest hope is that they can weather through it.

References

Curtis, M. C.‐U. (2014). Systematic review: Hygiene and health: systematic review of handwashing practices worldwide and update of health effects. Tropical Medicine & International Health, 906-916.