Do Loudspeaker Manufacturers Really Make Their Own Drivers?

Among the many things with which audio aficionados use to evaluate the engineering and technical expertise of their favored speaker companies, one thing certainly stands out:

Do they make their own drivers?

Why is this so important to the ardent hobbyist? Why does it seem to be such a bellwether of a company’s engineering bona fides?

The overriding thought is that a truly top-notch speaker company designs such sophisticated and specialized products that only custom-engineered and –manufactured drivers will fulfill the design’s requirements. Perhaps the bass response goals for the speaker are such that no “off-the-shelf” woofer is available that has the requisite low-frequency extension, the power-handling capability and the sensitivity to get the job done.

Likewise, it could be that the design engineer envisions a midrange or treble driver with a very specific set of electro/mechanical characteristics and no driver in readily-available land will do the trick.

But it’s one thing to specify the requirements to an outside 3rd-party fabricator and quite another thing to actually manufacture it yourself. These days it’s quite rare for speaker companies—even the big-name high-end companies—to actually make the drivers themselves in a US or Canadian or UK or Germany-based factory. It probably wouldn’t be an exaggeration to say it just doesn’t happen anymore.

However, the opposite used to be true. Most of the well-known brands actually made their own drivers right in their own factories, and then they assembled those drivers into finished goods, right on site. Some companies even had in-house cabinet-building facilities, so they built the cabinets, designed and built the drivers, assembled the finished speakers, tested them, boxed them up and shipped them out all from the same location.

The cabinet-building capability varied from company to company, but AR, KLH, Advent. Klipsch, JBL, EPI, Allison, Boston Acoustics, KEF, B&W and others were doing their own driver design and assembly right there in their home-based factories. I’ve been on several factory tours and seen the process myself.

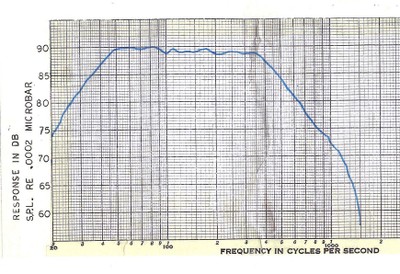

AR was justifiably proud of the performance and tight unit-to-unit tolerances of their MA-built drivers. Indeed, for pure FR performance, freedom from distortion, and other important characteristics, AR’s drivers from the late-50’s through the mid-70’s were arguably superior to anything being built back in the day. AR invented the dome driver, and AR’s acoustic suspension woofers (they also invented the “sealed” enclosure as we know it today) had ground-breaking LF extension and low distortion. The AR-3 of 1958 with its industry-first dome midrange and dome tweeter exhibited a remarkably refined, accurate performance, far ahead of the competition of the day. (See figure 1.)

Figure 1: Textbook-perfect AR woofer frequency response, 1954-1974

Image courtesy of Tom Tyson

The difficulty in all this wasn’t AR’s engineering of that period—which was way ahead of its time—it was that the manufacturing processes and materials of the middle of the 20th century were hard-pressed to keep up. Automated, robotic manufacturing was a long way off. Instead, much of AR’s manufacturing was done manually. (See figure 2.) The small dimensions of many of the parts and their incredibly tight QC tolerances led AR to reject a huge number of drivers before they ever found their way into finished goods.

Figure 2: AR-12-inch woofer, mid-1950’s, hand-treated surround

Image courtesy of Tom Tyson

AR used to literally brag about how many drivers they threw away and they pictured that in their advertising (see figure 3.) as a way to demonstrate how high their quality standards were.

Figure 3: AR-12-inch woofer rejects, in trash bins

Image courtesy of Tom Tyson

On a 1976 Boston Audio Society factory tour of the original Advent plant in Cambridge MA conducted by Advent president Andy Kotsatos (known then as Andy Petite), we saw the factory in action. By far the most fascinating part of the tour was the tweeter fabrication process. For those that remember, the Advent and Smaller Advent speakers were two-way designs that used a rather unique tweeter crossing over at a very low (for a two-way system) 1000 Hz. In order to be able to cross over that low, the driver had to have sufficient radiating area such that its sensitivity and air-moving capability would be satisfactory down to that low a frequency.

However, the driver had to maintain adequate dispersion and transient response well into the upper treble ranges.

These seemingly conflicting requirements were satisfied by a custom-designed 2-inch cone driver that became known as the Advent “doughnut” tweeter, because the outer part of the driver resembled the shape of a doughnut sitting on the kitchen counter. The inner part of the doughnut—the dustcap area—was dome-shaped, about 1” across in diameter. But the entire tweeter was one piece, not a separate cone with a separate inner dustcap. To Advent’s credit, they never explicitly said that the “inner dome” section of their tweeter diaphragm functioned like a 1-inch dome tweeter; like much of Advent’s cleverly-written ads and literature during that time period, they let the implication speak for itself. (See figure 4.)

Figure 4: Advent 2-inch “doughnut” tweeter

It was made from a light, stiff cellulose-based material. This was the most interesting part of the plant tour: There was a large vat of liquid “goop,” about the consistency of watery oatmeal. The operator would take what was, essentially, a large ladle and grab a serving of tweeter goop. He would then pour the goop into a press that would form the tweeter into its unique shape. Then, the pressed tweeter diaphragm was taken out of the press and put aside to dry. There were trays and trays of tweeter cones in the factory, ready to be assembled into finished tweeters.

That is making your own drivers.

Loudspeaker Manufacturers Make their Own Drivers? p2

Late 20th Century Drivers

During

the 50’s and 60’s, perhaps through the very early 70’s, most of the other

aforementioned companies made their own drivers in a similar fashion,

depending, of course, on the materials involved. Paper/cellulose woofer cones

were pressed and cut to shape, cloth surrounds were cut to shape and treated

for porosity-limitation, voice coils and crossover chokes were wound, often by

hand. It’s said that AR had a group of women who were so experienced and

skilled at assembling AR’s drivers—having done so for many, many years, since

the essential characteristics of many of AR’s drivers remained unchanged for

almost 20 years—that they could reportedly do this faster and more accurately

than any automated process.

During

the 50’s and 60’s, perhaps through the very early 70’s, most of the other

aforementioned companies made their own drivers in a similar fashion,

depending, of course, on the materials involved. Paper/cellulose woofer cones

were pressed and cut to shape, cloth surrounds were cut to shape and treated

for porosity-limitation, voice coils and crossover chokes were wound, often by

hand. It’s said that AR had a group of women who were so experienced and

skilled at assembling AR’s drivers—having done so for many, many years, since

the essential characteristics of many of AR’s drivers remained unchanged for

almost 20 years—that they could reportedly do this faster and more accurately

than any automated process.

That was fine for then, but as new production technology became available, companies found it possible to make larger quantities of drivers with fewer rejects and at lower unit cost.

By the late 1970’s, several companies still made their own drivers, but it had become more of a process of a company assembling their own drivers rather than actually making them.

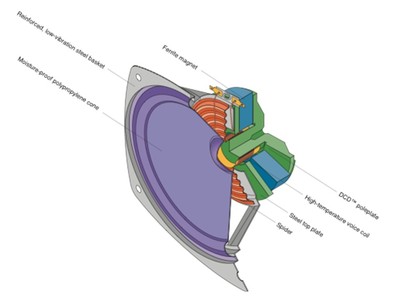

A very good example of this was Boston Acoustics. BA made virtually all their own drivers (with the exception of a tweeter here and there) from the time of the company’s inception in 1979 right up until the late 90’s or so. First, they had a battery of highly-skilled design engineers, armed with the very latest SOTA computers and programs, like FEA and the like. Once a driver design was done in the virtual world, it was given over to the Transducer Group who would then either assemble prototype drivers from an incredibly comprehensive inventory of parts (cones, domes, magnets, spiders, backplates, voice coils, etc. of every imaginable size and characteristic), or if needed, they’d order in custom parts (the magnet, the cone/surround, etc.) from their roster of specialized vendors and then complete the prototype driver. BA could make just about anything their engineers could design.

Once the project engineer was satisfied with the driver’s performance (and assuming it fit into the overall cost structure of the project’s budget), the driver would then be released into mass production in BA’s factory.

BA had a very sophisticated woofer line, where they’d make every cone driver they used, from the 2 ½” wide-range driver in their computer “cube” speakers right up to the 10” woofers they used in their TOTL home speakers.

But as I said, this was more “assembling” rather than “making.” BA would get baskets from one vendor, cones from another, spiders from a third, voice coils, dustcaps, surrounds, top plates, back plates, magnets (actually, just round hunks of metal with holes punched in them—they’d magnetize them right there on the line) and so on. They had a very impressive custom-designed assembly line, highly automated, that would combine all the various components into a finished driver in very little time. From start to finish, an 8” woofer might take about 5 minutes to go through the entire process, including going through a bake oven to cure and set the adhesives and passing through a QC chamber at the end, where it was swept and its FR etc. compared with the Engineering reference. Workers would then load the completed drivers onto pallets for storage in the raw parts area, until the next Work Order was generated that required that part. The drivers themselves were subject to +/- 1 dB tolerance (a 2 dB window across its operating band) and BA had surprisingly few rejects and therefore enjoyed a commendably low per-unit cost. They used good, consistent parts and the assembly process was very precise and buttoned-down. Quite, quite impressive. (See figure 5.)

Figure 5: Cutaway of BA woofer, 1996

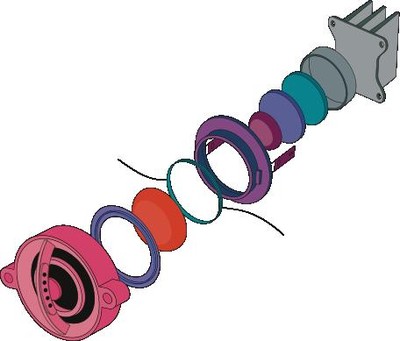

Their custom tweeter line was even more impressive. This line was sort of like BA’s “Manhattan Project,” very secretive, very advanced. BA didn’t allow factory visitors to take pictures of the tweeter line and they never showed a detailed image of it in any of their literature. It combined either aluminum dome/surround assemblies or textile (they called it “Kortec”) one-piece dome/surrounds with voice coils, Neodymium magnets, the backplate, under-dome felt “button,” and the faceplate with diffuser into tweeters of amazing quality and consistency. BA’s tweeter line was not only highly automated, it was self-diagnostic as well. When the tweeters went through the QC chamber at the end of the line, the readout would not only tell the operator whether the unit was “pass/fail,” but it would also tell them why the unit failed: too much adhesive (resulting in too much mass, for a reduced upper-octave response, or sensitivity too low (possibly from the magnet not being “seated” properly in the yoke) or not enough adhesive (leading to non-linear excursion, so the distortion was too high), etc.

After that particular build, all the failures were analyzed and the line would automatically self-adjust to further optimize the amount of adhesive dispensed, the parts placement motions, etc. so the tweeters got better and better as time passed. Eventually, they were almost flaw-free, +/- 1 dB from 2000-20 kHz. Ruler flat. The tweeters were so good and so consistent that even after BA shifted most of its finished-goods production to China, they’d still make tweeters in MA and ship them over! It was less expensive to do it that way than to QC an incoming all-China shipment and find that 5% of the tweeters didn’t pass. (See figure 6.)

Figure 6: Exploded view of BA tweeter, 1994-2003

I don’t know if BA still does that, but they did as late as 10 years ago.

Loudspeaker Manufacturers Make their Own Drivers? p3

Nowadays,

companies in the US, Canada, the UK or Germany rarely—if ever— manufacture

their own drivers. They don’t even assemble them in-house. They “custom-design”

them and then have them “made exclusively for them.” Look at the lit from your

favorite super-duper speaker company. They’ll almost all say something along

those lines.

Nowadays,

companies in the US, Canada, the UK or Germany rarely—if ever— manufacture

their own drivers. They don’t even assemble them in-house. They “custom-design”

them and then have them “made exclusively for them.” Look at the lit from your

favorite super-duper speaker company. They’ll almost all say something along

those lines.

But, man, that’s a gap you can drive a Mack truck through!

This is not meant to denigrate the design process or the good intentions of most speaker companies. The better companies have extensive in-house design and virtual modeling capabilities, and most good companies have extensive measurement and evaluation capabilities as well. It’s just that with the realities of today’s economics and labor costs, it’s simply less expensive to do the actual manufacturing overseas—usually in China.

Therefore, the process usually goes something like this: The project’s design engineers—working from Marketing’s Product Definition of what they need, and why, in order to be successful in the marketplace—determine whether or not they need new drivers for the project, or whether existing drivers from past products will suffice.

Let’s say Marketing has requested a bookshelf speaker that is no bigger than .6 cubic foot interior volume (about 1000 cu.in.) with a maximum depth dimension of 12 inches, so it will actually fit on a bookshelf. But Marketing had determined through its research that of its main competitors at +/- $100 of the project’s target retail price, none goes lower than -3 dB at 55 Hz. So Marketing waves its hand towards Engineering and says, “Give me a bookshelf speaker that hits -3 dB at 45 Hz, so we can brag about a legitimate, audible difference. And don’t make it need a ton of power in a small box—we need a sensitivity of at least 86 dB 2.83 V at 1M. And don’t bust the budget by requiring a huge expensive magnet to give you the Bl. Oh, and we need it in 6 months, in time for the holidays. When can I hear the first prototype?”

After several single-malts, the engineers realize that they need a brand new woofer. So they painstakingly design one that optimizes all the variables, closes the VC gap to a small enough dimension that the magnetic field in the gap will be strong enough even with a normal-sized magnet to hit the sensitivity target (a small VC gap dimension is tougher to manufacture, but they’ll hold the vendor’s feet to the fire), uses a very compliant surround and spider so the FAR can be kept low even though the cone’s mass has to be light to maintain sensitivity (all these conflicting requirements—welcome to the engineer’s nightmare world!), and so on.

The design is finally complete and they send the specs and requirements off to the driver vendor overseas. Now they wait to see what they get back. It’s always a surprise, and not usually a good one.

Three prototype woofer samples come in after waiting for 6 weeks. They’re way off. The FAR is too high. The VC gap is too large. The magnet is too bulky. The FR has a bad 6 dB spike at 1500 Hz because of an edge reflection. It seems as if the driver vendor just disregarded all the subtle design aspects the U.S. speaker company sent them and simply sent back some off-the-shelf woofers.

That’s exactly what they did, of course.

Many overseas driver vendors—even the well-known “brand-name” driver companies that hobbyists are oh-so-impressed with—will try to take the easy route first. They try this because many times it works. If the driver is “close enough,” the US company can work with it and make it all come out OK by manipulating the crossover or some other design detail.

But if the U.S. company really pushes back hard, then the driver vendor will get to work and deliver what was specified in the first place. (To the best of their ability, anyway. The language barrier is ruinous in many instances when trying to communicate subtleties and many driver vendors suddenly can’t understand English when they’re asked to do something time-consuming, detailed, or difficult. They all understand English perfectly well, however, when it comes time to read their invoice and pay them.)

The corrected woofer prototypes finally come in. They look great. They measure nicely. The U.S. company is excited because they see a successful path to the project’s completion. The two companies execute a formal agreement that this driver is the exclusive intellectual property of the two of them alone, and the vendor will not make or sell this driver to anyone else.

But the driver vendor announces that these woofers are difficult to make, so they’ll cost 30% more than the original target. The first ones they sent in (the ones that were way off, totally unusable) are priced exactly at the target cost.

Welcome to the real world of product development. This is how it goes. Do you “eat” the cost increase and make no money on the product? Do you raise the retail price and lose your marketplace advantage? Do you split the difference?

After going through all this aggravation and finally getting their design built correctly, many speaker companies feel they’ve earned the “right” to say, “Hey—it’s our driver!” This is where the vast majority of “make our own drivers” claims come from.

Aaaah, but there’s one thing—remember that “formal agreement” we just spoke about, the one that said the driver vendor would not make or sell this driver to anyone else? Well, that was true, but with one huge caveat: “…. as long as the Speaker Company agrees to purchase at least xx,xxx units per year.” If the Speaker Company misses that purchase agreement by even one unit, you’ll see those things showing up in every catalog and on-line supplier there is. Often, it’ll be pretty darn obvious whose driver it originally was—that adds immeasurably to the attraction and salability of the item. The overseas driver vendor is in business to make a profit selling drivers. They invest a lot of their time and expertise developing the production methods, the tooling, everything. They base their projected return on the sale of xx,xxx units in order to amortize their costs. If the original Speaker Company doesn’t buy them, they’ll sell them somewhere else. Anywhere else as you can see in the example below courtesy of Dayton Audio.

Many times, a vendor will modify the "exclusive" driver ever so slightly, to 'keep the door open' for their original customer to get back in their good graces. Future work is at stake and the overseas vendor has an eye on not ticking off their US or Canadian or UK customer to the point where that company will go to a different Chinese vendor next time they need a custom driver. This Dayton tweeter is a good example of that likely being the case: close enough in appearance and general specs to have the lure and appeal of the big-name company that used the driver, but just enough different that both the vendor and the original company can say that it's not the exact same driver. This is the delicate balancing act--the tug-of-war--that happens every day behind the scenes.

Dayton Audio 1” DC-25T Titanium Dome Tweeter

The painstaking design of a truly original driver, the evaluation of six rounds of prototypes, the feedback, the trying again until it’s finally right, that’s a totally legitimate process and the designing Speaker Company in the U.S. or Canada or the UK has every right to call that unique design “their” driver. It is their driver.

But, there are other, lesser levels of “we make our own drivers” these days, and some of them are kind of, well, sleazy.

Driver vendors have huge inventories of parts that can be customized to any company’s needs. Many times, a company will go to their vendor and say, “We need blue metallic cones.” It’s the exact same woofer as the one with the black poly cone, but this one was molded in blue metallic. Looks different, but performs the same and costs the same (or maybe a few cents more.) Same with tweeters—you can get a “metallic look” on a standard cloth dome, by doing a quick vapor-deposit spray with some silver-look paint. Voilá! Instant “metallic” dome.

“Our exclusive tweeter was custom-engineered by our in-house design team to provide the quickness and transient characteristics of the best metal domes, while retaining the critical self-damping traits of a cloth dome. The result is exquisite detail and sparkle, but without the harshness usually associated with conventional metal domes.”

Wow. Sounds impressive. “Our exclusive tweeter.” Yup, we approved the paint color from the six paint samples they sent us. Now it’s “our” tweeter.

Conclusion

As

you can see, the concept of “making our own drivers” has changed quite a bit

over the years. However, there is nothing inherently wrong or bad about using

commercially-available drivers. There are so many driver companies making so

many different drivers at all price/performance levels in every conceivable

configuration that a talented—and resourceful!—speaker designer can undoubtedly

find the drivers he needs to suit almost any requirement.

As

you can see, the concept of “making our own drivers” has changed quite a bit

over the years. However, there is nothing inherently wrong or bad about using

commercially-available drivers. There are so many driver companies making so

many different drivers at all price/performance levels in every conceivable

configuration that a talented—and resourceful!—speaker designer can undoubtedly

find the drivers he needs to suit almost any requirement.

Sometimes you design your own, and you call it “your” driver. Sometimes you look for something already available and use it with perfectly excellent results. In the end, it’s the skill and vision of the product’s designer that determines the quality of the sound, regardless of where or how the drivers were built.