Speaker Cable Faceoff 3 - The DIY Shootout

This effort is an offshoot of my search for a decent performing large OD cable, which will be used for my DIY speaker cables. When I bought my first really good pair of speakers, the salesman sort of talked me into a set of Monster MCX-1S cables. I had been/ am a zip cord type of guy and did not know any better. Well, after purchasing those particular cables, and speakers, I had a bit of buyers remorse. Not over the $1400 pair of speakers, but the $75 pair of cables. At the time, my wife and I were dismantling the recording studio we had in the basement and selling it off in pieces, and saving some for a home theater. And after a lot in internet searches, I found Audioholics among others, and my education really started.

I have always had a bigger is better philosophy, as well as a devote DIYer. So after reading all I could about speaker cables, I started on my path to building a bigger (and better) mouse trap. I wanted diameter as well as performance. I also had the tools to determine which was better. I have my own LCR meter, a BK Precision Model 885. Granted this is no Wayne Kerr model 6420 with unobtanium leads and a $15000 price tag like Audioholics uses in their Test Equipment Arsenal, but it is suitable for most home grown/military applications and cost less than $1000. Not much less, but less (even with the Kelvin clips). Nor does it generate gigahertz frequencies, it maxes out at 10000 Hz. Which is fine with me, after all I cannot hear anything over 16000 Hz so why test speaker cables at 1 GHz? Video cables are another matter, but not in this paper.

So, let's get to the meat of the order.

Cable Descriptions and Comments

The cables tested include some standard speaker cables, and some readily available power or control cable from various sources. I acquired all cable at my own cost. Costs range from $0.21/foot to $16.00/foot (of course to get this particular cable at this price you have to buy 1000 feet). Anyway, some of the cables were tested in a couple of different ways, and some were tested straight. The table below is a list of the tested cables and their construction.

|

Manufacturer |

Model |

AWG |

Strand Count |

Conductors Per Cable |

Conductors Used |

Construction |

|

Alpha |

85104CY |

10 |

658 x 38 |

4 |

2 |

Twisted Lay |

|

Carol |

10/3 |

10 |

104 x 30 |

3 |

2 |

Twisted Lay |

|

Carol |

12/4 |

12 |

65 x 30 |

4 |

2 |

Twisted Lay |

|

CAT 5 |

V1 |

12 |

16 x 24 |

4 |

4 |

Twisted Lay |

|

CAT 5 |

V2 |

12 |

16 x 24 |

4 |

4 |

Flat Braid |

|

CAT 5 |

V3 |

10 |

24 x 24 |

6 |

6 |

Twisted Lay |

|

CAT 5 |

V4 |

10 |

24 x 24 |

6 |

6 |

Flat Braid |

|

CAT 5 |

V5 |

10 |

24 x 24 |

6 |

6 |

Twisted Braid |

|

Generic |

10/4 |

10 |

104 x 30 |

4 |

2 |

Twisted Lay |

|

Generic |

12/4 |

12 |

65 x 30 |

4 |

2 |

Twisted Lay |

|

Monster |

MCX-1S |

NA |

NA |

2 |

2 |

Twisted Lay |

|

Parts Express |

Part Number 100-768 |

14 |

41 x 30 |

4 |

2 |

Twisted Lay |

|

Sound King |

V1 |

10 |

413 x 36 |

2 |

2 |

Flat Lay |

|

Sound King |

V2 |

10 |

413 x 36 |

2 |

2 |

Twisted Lay |

|

Sound King |

V3 |

10 |

413 x 36 |

2 |

2 |

3 Wire Braid |

|

Sound King |

V4 |

10 |

413 x 36 |

2 |

2 |

4 Wire Braid |

|

Woods |

HD Contractors Cord |

12 |

NA |

3 |

2 |

Twisted Lay |

TESTED CABLES and CONSTRUCTION

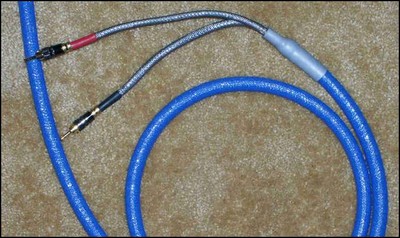

Unless otherwise stated, all cables were finished with WBT Clone, crimp style, locking banana plugs (see Figure 1).

FIGURE 1

WBT Clone (GLS) Locking Banana Plugs use for all cable ends

Alpha 85104CY (10/4 shielded)

I acquired 48 feet at a garage sale for $25. I thought this might be great performing cable because of it's high strand count, shielding, and gauge. Internet research indicates a retail price of $16/foot through Allied Electronics with a 1000 foot minimum. It is a marine grade control cable, very flexible, with a very supple feel to it. If I wanted one cable to really perform in my test it would be this one, mainly because of it's ¾ inch diameter, and 3X bend radius. Only two opposing conductors were measured, leaving the adjacent conductors unused.

Carol Cable

I bought 50 feet each through Parts Express of 10/3 (Part Number 100-58 for $33.15), and 12/4 (Part Number 100-590 for $33.10). Price does not include shipping charges. I made three tests with the Carol 12/4 cable: The first test was made the way all other four conductor cables would be tested, in this method, only two opposing conductors would be measured. For the second and third tests, I made a rig so that I could use the two unused conductors to power a 500 watt photo lamp (second test) and drive a speaker playing pink noise (third test). The reason for the second and third test was based on my post in the A/V Connections Forum and my question to John Escallier (aka jnuetron) about how a signal may be affected by signals in near by wires.

- T1 - Two conductors out of four used.

- T2 - Two conductors used for evaluation purposes, and two conductors used to power a 500 watt photo lamp.

- T3 - Two conductors used for evaluation purposes, and two conductors used to power a speaker playing pink noise at 75 dB C weighted.

Cat 5

I have read about using cat 5 wire as a speaker cable, but I was not that interested in braiding all those tiny wires hundreds of times. Then I though that since the wire pairs run rather loosely inside the outer covering, how would they test out if I made speaker cables using the entire package? Since cat 5 is just a twisted bunch of 24 gauge wires, I figured that 16 wires was roughly equal to 12 gauge litz wire and 24 wires was roughly equal to 10 gauge litz wire, viola, 4 and 6 individual lengths of cat 5 would be all I need. I took about 100 feet of cat 5 wire where I work and cut it into 10 foot lengths, attaching all wires (left inside the sheath) to banana plugs (see Figure 7). The prices shown in table 5 are based on prices from Parts Express and the number of 10 foot lengths used and does not include the connectors. I used these cables in five different variations using 4 or 6 cables. See Figures 2 through 6 for descriptions.

As I started with many 10 foot lengths, the overall length of the speaker cable was somewhat shorter after twisting and braiding. This shorter length of each version is used below when determining Rs, Cp, and Ls on a per foot basis.

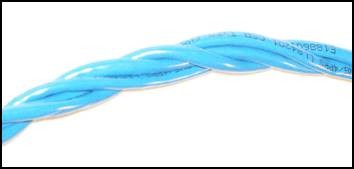

FIGURE 2

CAT 5 - V1 Four Twisted Cables

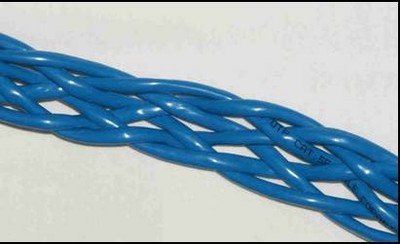

FIGURE 3

CAT 5 - V2, Four Cables Braided

FIGURE 4

CAT 5 - V3, Six Twisted Cables

FIGURE 5

CAT 5 - V4, Six Cables Braided

FIGURE 6

CAT 5 - V5, Six Cables in Three Twisted Pairs Braided

Typical Cable Ends Finished for Testing

Generic

I do not know the brand name of these cables, but they are available at Lowes. The 10/4 cost $1.74/ft and the 12/4 costs $1.46 per foot. I purchased these after being very impressed by the supple feel, flexibility, and large diameter. Both cables have some sort of polyester fill between cables, and the 12 gauge cable has a white polyurethane sheathing inside the rubber external sheath. Both cables have the same OD. 20 feet of each was purchased and the entire length was used in testing.

DIY Cable Faceoff - Testing and Methodology

Cables from Lowes. 12/4 is on left & 10/4 is on right. Both have a 0.75" OD

Monster MCX-1S

I bought this cable from Tweeter when I bought my Mirage Speakers. The 10 foot pair of cables is $50, but, unless you want to use the pins, you need to purchase the Monster banana plugs or spades which cost another $12.50 for four (and you need a total of 8 for the pair of cables).

Parts Express

As the name implies, do not know the manufacturer, but thought is may be a nice to include. This is a 14 gauge, 4 conductor cable.

Sound King

I bought a 100 foot spool of 10 AWG speaker wire from Parts Express. I liked the large strand count. Anyway, I cut several 10 foot lengths of this zip wire and tested four variations of this cable. See Figures 9 through 12 for descriptions.

The same comment here as with the CAT 5 cables. As I started with many 10 foot lengths, the overall length of the speaker cable was somewhat shorter after twisting and braiding. This shorter length of each version is used below when determining Rs, Cp, and Ls on a per foot basis.

FIGURE 9

Sound King 10 AWG Zip Wire (V1 in following Tables)

FIGURE 10

Sound King 10 AWG Twisted (V2 in following Tables)

FIGURE 11

Sound King 10 AWG Three Wire Braid (V3 in following Tables)

FIGURE 12

Sound King 10 AWG Four Wire Braid (V4 in following Tables)

Woods

This is a generic 25 foot heavy duty 12/3 extension cord purchased from Home Depot for $16.

Testing

All measurements were made on a BK Precision Model 885 LCR meter using the optional Kelvin Clips. This meter has several functions which are very suitable for my purposes. This meter can measure capacitance, inductance, and AC resistance at 100, 120, 1000, and 10000 Hz. However, since I’m using excel to plot everything in a log format I did not bother with the 120 Hz measurements. Prior to making each measurement, the meter was run through a self calibration test.

Figure 13 - Test Gear

Methodology

As stated above, the LCR measurements were made at 100 Hz, 1kHz, and 10kHz. The measured parameters were then averaged. The averages were used to evaluate the cables against each other and to cables from the two cable face-offs performed by Audioholics.

The evaluation process involved generating a dimensionless number based on linear interpolation.

By setting the worst case average, in each case this is the highest average, to 1, and the best average (the lowest) to 10, and interpolating for those averages between the best and worst to develop the dimensionless factors for all cables.

After all factors were calculated, weight factors were applied. These weight factors were arrived at after numerous email discussions between Gene DellaSala, John Escallier, and myself. For the most part, I just sat back and said uh-uh. Anyway, we arrive at the following weight factors.

| Resistance | 0.41 |

| Inductance | 0.32 |

| Capacitance | 0.27 |

| Technical Factor | 0.6 |

| Cost | 0.4 |

The way this system works is to apply the weight factor to the dimensionless factors for resistance, inductance, and capacitance and arrive at a Technical Weighted Ranking Number (TWRN). The TWRN then has the technical weight factor applied and is summed with the cost dimensionless factor and the cost weight factor to finally arrive at a Final Weighted Ranking Factor (FWRF). The highest FWRF wins.

This method was also used to compare the results of both cable face-offs, and the total combined results of my analysis and both cable face-offs. Check the tables, the results are surprising.

References: Speaker Cable Face Off 1 and Speaker Cable Face Off 2

DIY Cable Faceoff - Measurements and Value

Resistance (Rs)

The results of the resistance measurements are shown in Table 3, as previously stated, the higher the rank, the better. I’ve only shown Rs for each frequency. Rs is the AC resistance at the measured frequency plus the DC resistance.

|

Manufacturer |

Model |

Rs (Ohms/Ft) |

RANK |

|||

|

100 Hz |

1kHz |

10kHz |

AVG |

|||

|

Alpha |

85104CY |

0.00208 |

0.00213 |

0.00228 |

0.00216 |

9.858 |

|

Carol |

10/3 |

0.00204 |

0.00205 |

0.00206 |

0.00205 |

10.000 |

|

Carol |

12/4 T1 |

0.00329 |

0.00329 |

0.00341 |

0.00333 |

8.322 |

|

CAT 5 |

V1 |

0.00269 |

0.00269 |

0.00269 |

0.00269 |

9.161 |

|

CAT 5 |

V2 |

0.00326 |

0.00326 |

0.00344 |

0.00332 |

8.336 |

|

CAT 5 |

V3 |

0.00213 |

0.00218 |

0.00224 |

0.00218 |

9.824 |

|

CAT 5 |

V4 |

0.00216 |

0.00215 |

0.00231 |

0.00221 |

9.797 |

|

CAT 5 |

V5 |

0.00222 |

0.00227 |

0.00227 |

0.00225 |

9.736 |

|

Generic (Lowes) |

10/4 |

0.00202 |

0.00210 |

0.00232 |

0.00215 |

9.870 |

|

Generic (Lowes) |

12/4 |

0.00325 |

0.00325 |

0.00345 |

0.00332 |

8.345 |

|

Monster |

MCX-1S |

0.00861 |

0.00882 |

0.00937 |

0.00893 |

1.000 |

|

Parts Express |

100-768 |

0.00521 |

0.00536 |

0.00536 |

0.00531 |

5.742 |

|

Sound King |

V1 |

0.00207 |

0.00222 |

0.00222 |

0.00217 |

9.850 |

|

Sound King |

V2 |

0.00210 |

0.00224 |

0.00224 |

0.00220 |

9.808 |

|

Sound King |

V3 |

0.00210 |

0.00224 |

0.00224 |

0.00220 |

9.808 |

|

Sound King |

V4 |

0.00210 |

0.00215 |

0.00217 |

0.00214 |

9.884 |

|

Woods |

HD |

0.00333 |

0.00343 |

0.00345 |

0.00340 |

8.232 |

|

Carol |

12/4 T2 |

0.00329 |

0.00329 |

0.00341 |

0.00333 |

NA |

|

Carol |

12/4 T3 |

0.00329 |

0.00329 |

0.00341 |

0.00333 |

NA |

TABLE 2

CABLE RESISTANCE (Ohms/Ft)

Editorial Note

The 1-10 scale ranks the cable resistance for each cable. The higher the #, the lower the resistance or the better performance the cable will yield in this respect.

Note, that as expected, the photo lamp test (T2) and the pink noise test (T3), did not affect the resistance of the conductors in a 4 conductor cable. Notice also, the high resistance of the Monster cable, this is characteristic of a 16 AWG or smaller wire.

Capacitance (Cp)

|

Manufacturer |

Model |

Cp (picofarads/Ft) |

RANK |

|||

|

100 Hz |

1kHz |

10kHz |

AVG |

|||

|

Alpha |

85104CY |

45.241 |

41.959 |

38.097 |

41.7657 |

1.364 |

|

Carol |

10/3 |

37.625 |

35.063 |

32.250 |

34.9792 |

3.439 |

|

Carol |

12/4 T1 |

27.808 |

25.769 |

24.654 |

26.0769 |

6.161 |

|

CAT 5 |

V1 |

26.915 |

26.863 |

26.056 |

26.6115 |

5.997 |

|

CAT 5 |

V2 |

24.825 |

23.776 |

23.310 |

23.9705 |

6.805 |

|

CAT 5 |

V3 |

38.105 |

42.663 |

41.105 |

40.6246 |

1.713 |

|

CAT 5 |

V4 |

32.000 |

32.222 |

31.333 |

31.8519 |

4.395 |

|

CAT 5 |

V5 |

40.432 |

44.865 |

43.568 |

42.9550 |

1.000 |

|

Generic (Lowes) |

10/4 |

16.000 |

18.600 |

17.500 |

17.3667 |

8.824 |

|

Generic (Lowes) |

12/4 |

15.600 |

18.450 |

17.350 |

17.1333 |

8.896 |

|

Monster |

MCX-1S |

29.720 |

35.710 |

34.890 |

33.4400 |

3.909 |

|

Parts Express |

100-768 |

22.400 |

21.020 |

20.000 |

21.1400 |

7.670 |

|

Sound King |

V1 |

22.900 |

20.800 |

18.730 |

20.8100 |

7.771 |

|

Sound King |

V2 |

21.128 |

19.897 |

18.154 |

19.7265 |

8.103 |

|

Sound King |

V3 |

12.410 |

14.626 |

13.528 |

13.5214 |

10.000 |

|

Sound King |

V4 |

20.886 |

19.697 |

18.314 |

19.6324 |

8.131 |

|

Woods |

HD |

33.320 |

35.000 |

32.160 |

33.4933 |

3.893 |

|

Carol |

12/4 T2 |

26.000 |

26.192 |

24.962 |

25.718 |

NA |

|

Carol |

12/4 T3 |

28.231 |

25.962 |

24.769 |

26.321 |

NA |

TABLE 3

CABLE CAPACITANCE (pF/foot)

Editorial Note

The 1-10 scale ranks the cable capacitance for each cable. The higher the #, the lower the capacitance or the better performance the cable will yield in this respect.

Several thing to notice from these results are the very good performance of the standard off the shelf power cables. While the Woods extension cord does not appear to be exemplary in this respect, it is comparable to the more popularly known Monster cable. The two cables I purchased at Lowes really impress though, as does the Sound King. Bare in mind the Sound King V3 is a three wire braid and the V4 is a 4 wire chain braid. It seems that inexpensive wire rules here. A final note, the photo lamp test (T2) and pink noise test (T3) do not appear to have a minor impact on capacitance, but this is also within the realm of standard meter error.

Inductance (Ls)

|

Manufacturer |

Model |

Ls (microHenries/Ft) |

RANK |

|||

|

100 Hz |

1kHz |

10kHz |

AVG |

|||

|

Alpha |

85104CY |

0.217 |

0.210 |

0.215 |

0.214 |

4.332 |

|

Carol |

10/3 |

0.262 |

0.260 |

0.253 |

0.258 |

2.393 |

|

Carol |

12/4 T1 |

0.256 |

0.254 |

0.251 |

0.254 |

2.592 |

|

CAT 5 |

V1 |

0.112 |

0.095 |

0.104 |

0.104 |

9.162 |

|

CAT 5 |

V2 |

0.115 |

0.132 |

0.126 |

0.124 |

8.264 |

|

CAT 5 |

V3 |

0.097 |

0.096 |

0.089 |

0.094 |

9.587 |

|

CAT 5 |

V4 |

0.123 |

0.122 |

0.116 |

0.120 |

8.432 |

|

CAT 5 |

V5 |

0.088 |

0.086 |

0.080 |

0.085 |

10.000 |

|

Generic (Lowes) |

10/4 |

0.256 |

0.255 |

0.251 |

0.254 |

2.582 |

|

Generic (Lowes) |

12/4 |

0.290 |

0.282 |

0.284 |

0.285 |

1.208 |

|

Monster |

MCX-1S |

0.195 |

0.192 |

0.186 |

0.191 |

5.340 |

|

Parts Express |

100-768 |

0.218 |

0.203 |

0.210 |

0.210 |

4.489 |

|

Sound King |

V1 |

0.210 |

0.196 |

0.203 |

0.203 |

4.810 |

|

Sound King |

V2 |

0.217 |

0.215 |

0.209 |

0.214 |

4.327 |

|

Sound King |

V3 |

0.258 |

0.246 |

0.253 |

0.252 |

2.641 |

|

Sound King |

V4 |

0.299 |

0.281 |

0.289 |

0.290 |

1.000 |

|

Woods |

HD |

0.190 |

0.190 |

0.183 |

0.187 |

5.493 |

|

Carol |

12/4 T2 |

0.254 |

0.253 |

0.249 |

0.252 |

NA |

|

Carol |

12/4 T3 |

0.256 |

0.247 |

0.249 |

0.251 |

NA |

TABLE 4

CABLE INDUCTANCE (μH/Ft)

Editorial Note

The 1-10 scale ranks the cable inductance for each cable. The higher the #, the lower the inductance or the better performance the cable will yield in this respect.

Cable

Metric Definitions

|

CAT 5 rules, as expected. Extension cords almost rule as not expected. I wonder why the braided Cat 5 wire performed so much better than the braided Sound King. Let’s not start the argument that Cat 5 is designed for low inductance, especially since the way I made the cables - each of the eight wires inside the sheath acted as one thick wire, the same way as the Sound King cable. It would be nice to hear some knowledgeable opinions or even swags. Finally though, the Monster cable is at least looking mediocre.

Editorial Note

By

braiding multiple conductors in close proximity you have taken

advantage of mutual inductance by cancellation of self inductance to

minimize the overall inductance of the cable. For more detailed

information on cable inductance check out our article: Calculating Cable Inductance

Value and Price

|

Manufacturer |

Model |

Price/Ft |

Rank |

|

Alpha |

85104CY |

$16.00 |

1.000 |

|

Carol |

10/3 |

$0.66 |

9.756 |

|

Carol |

12/4 T1 |

$0.66 |

9.756 |

|

CAT 5 |

V1 |

$0.26 |

9.985 |

|

CAT 5 |

V2 |

$0.23 |

10.000 |

|

CAT 5 |

V3 |

$0.37 |

9.923 |

|

CAT 5 |

V4 |

$0.33 |

9.943 |

|

CAT 5 |

V5 |

$0.32 |

9.948 |

|

Generic (Lowes) |

10/4 |

$1.74 |

9.140 |

|

Generic (Lowes) |

12/4 |

$1.46 |

9.300 |

|

Monster |

MCX-1S |

$3.75 |

7.992 |

|

Parts Express |

100-768 |

$0.34 |

9.939 |

|

Sound King |

V1 |

$0.72 |

9.722 |

|

Sound King |

V2 |

$0.74 |

9.712 |

|

Sound King |

V3 |

$1.11 |

9.501 |

|

Sound King |

V4 |

$1.56 |

9.244 |

|

Woods |

HD |

$0.64 |

9.768 |

TABLE 5

CABLE COST ($/Ft)

Editorial Note

The 1-10 scale ranks the cable cost for each cable. The higher the #, the lower the cost or the better value to the consumer.

The cost per foot shown in Table 5 is based on one cable for one channel. So you will need to double the cost for a pair of speaker cables. The thing to observe here is that the least expensive cables require the most work. Do you have any idea how tiring it is to neatly braid Cat 5? Also notice that all cables except the Monster and Alpha have rankings above 9. That is because the cost of the Alpha wire is so much more than all others. In my field (mechanical engineering) we would almost call this a wash. Yes the cable from Lowes is almost 8 times as expensive as the cheapest Cat 5 variant, but you just have to put connectors of you choice on the Lowes cable - no assembly required. When these cables are compared to other esoteric cables (see Table 7) that $16/foot may not seem so expensive anymore.

DIY Cable Faceoff - Results and Conclusion

Speaker Cable Face Off II previously conducted by Audioholics provided a lot of meaningful information, but no clear idea of which was best. While we are waiting on Gene to finish his cable analysis in Face Off II, I thought I would assign ranking based on his measurements using my linear interpolation method. So, here before you, I give you my opinion on which of these cable is the best. Granted, my opinion is worth is weight in copper (I would have said gold, but the resistance is too high, definitely not silver as it tarnished too easily). All of those ranking numbers contained in tables 2-5 are put to use right now. But first let us discuss weight factors. I have measured three electrical parameters of each of these cables (Resistance, Inductance, Capacitance), and know from first hand experience how much each cable cost me to make. So now we (in the royal sense) decided which factors are the most important based on an educated estimation their impacts may have on system stability and frequency response variation. Under different circumstances, each parameter measured may rise in importance. For very long cable runs all three may be of equal importance, but I think we should just consider normal runs of less then thirty feet (since the longest cable I measured was 26 feet). Based on this, we assigned rankings for each metric with a certain weight function based on perceived importance. Therefore, Resistance is weighted at 41%, Inductance is weighted at 32%, Capacitance is weighted at 27%. These technical factors are weighted at 60% and Cost is weighted at 40%.

|

RESULTS BASED ON RANK FACTORS |

|||||||||

|

|

|||||||||

|

Manufacturer |

Model |

Weight Factors |

Final Weighted Ranking Number |

Technical Rank |

Final Rank |

||||

|

0.41 |

0.32 |

0.27 |

0.6 |

0.4 |

|||||

|

R |

L |

C |

Technical Weighted Ranking Number |

Cost |

|||||

|

CAT 5 |

V1 |

9.161 |

9.162 |

5.997 |

8.30704 |

9.985 |

8.97822 |

1 |

1 |

|

CAT 5 |

V2 |

8.336 |

8.264 |

6.805 |

7.89959 |

10.000 |

8.73975 |

3 |

2 |

|

CAT 5 |

V4 |

9.797 |

8.432 |

4.395 |

7.90166 |

9.943 |

8.71820 |

2 |

3 |

|

CAT 5 |

V3 |

9.824 |

9.587 |

1.713 |

7.55819 |

9.923 |

8.50411 |

7 |

4 |

|

Sound King |

V1 |

9.850 |

4.810 |

7.771 |

7.67587 |

9.722 |

8.49432 |

4 |

5 |

|

CAT 5 |

V5 |

9.736 |

10.000 |

1.000 |

7.46176 |

9.948 |

8.45626 |

8 |

6 |

|

Sound King |

V2 |

9.808 |

4.327 |

8.103 |

7.59373 |

9.712 |

8.44104 |

5 |

7 |

|

Sound King |

V3 |

9.808 |

2.641 |

10.000 |

7.56640 |

9.501 |

8.34024 |

6 |

8 |

|

Generic (Lowes) |

10/4 |

9.870 |

2.582 |

8.824 |

7.25542 |

9.140 |

8.00925 |

9 |

9 |

|

Sound King |

V4 |

9.884 |

1.000 |

8.131 |

6.56781 |

9.244 |

7.63829 |

10 |

10 |

|

Woods |

HD |

8.232 |

5.493 |

3.893 |

6.18399 |

9.768 |

7.61759 |

12 |

11 |

|

Parts Express |

100-768 |

5.742 |

4.489 |

7.670 |

5.86160 |

9.939 |

7.49256 |

14 |

12 |

|

Generic (Lowes) |

12/4 |

8.345 |

1.208 |

8.896 |

6.20993 |

9.300 |

7.44596 |

11 |

13 |

|

Carol |

12/4 T1 |

8.322 |

2.592 |

6.161 |

5.90493 |

9.756 |

7.44536 |

13 |

14 |

|

Carol |

10/3 |

10.000 |

2.393 |

3.439 |

5.79429 |

9.756 |

7.37897 |

16 |

15 |

|

Monster |

MCX-1S |

1.000 |

5.340 |

3.909 |

3.17423 |

7.992 |

5.10134 |

17 |

16 |

|

Alpha |

85104CY |

9.858 |

4.332 |

1.364 |

5.79630 |

1.000 |

3.87778 |

15 |

17 |

TABLE 6

MUDCATS CABLE FACE OFF FINAL RESULTS

Editorial Note

The 1-10 scale ranks the overall score of the cable regarding technical and final rankings. The lower the #, the better the cable scored with respect to the test criteria, where the technical ranking is based solely on performance and the Final ranking also factors in value.

Surprisingly the Monster Cables performance was outclassed by extension cord. For ease of construction, I preferred the 10/4 cable from Lowes with techflex and banana plugs resulting in a nice looking, large diameter garden hose – err speaker cable. of the technical tidbits (Resistance, Inductance, and Capacitance) and does not include any cost factors.

For your continued enjoyment, I've included a table comparing all the cables I tested and all the cables from Audioholics two previous cable face-offs. If you do not like the results, change the weight factors.

|

Brand |

Model |

Source |

Weight Factor |

Overall Final Weighted Factor |

Technical Rank |

Final Rank |

||||

|

0.41 |

0.32 |

0.27 |

0.6 |

0.4 |

||||||

|

Resistance |

Inductance |

Capacitance |

Technical Weighted Ranking Factor |

Cost |

||||||

|

CAT 5 |

V5 |

Mudcat |

9.191 |

8.220 |

8.893 |

8.800 |

9.995 |

9.278 |

1 |

1 |

|

CAT 5 |

V3 |

Mudcat |

9.246 |

7.963 |

8.958 |

8.758 |

9.993 |

9.252 |

2 |

2 |

|

CAT 5 |

V1 |

Mudcat |

8.845 |

7.696 |

9.347 |

8.613 |

9.998 |

9.167 |

3 |

3 |

|

CAT 5 |

V4 |

Mudcat |

9.228 |

7.237 |

9.202 |

8.584 |

9.995 |

9.148 |

4 |

4 |

|

CAT 5 |

V2 |

Mudcat |

8.347 |

7.126 |

9.421 |

8.246 |

10.000 |

8.948 |

9 |

5 |

|

Cobalt Cable |

10 AWG |

CFO |

9.518 |

5.705 |

9.621 |

8.326 |

9.654 |

8.857 |

7 |

6 |

|

Axiom Audio |

Speaker Cable |

CFO II |

8.174 |

7.856 |

9.018 |

8.300 |

9.677 |

8.851 |

8 |

7 |

|

Sound King |

V1 |

Mudcat |

9.257 |

4.957 |

9.508 |

7.949 |

9.975 |

8.759 |

14 |

8 |

|

Sound King |

V2 |

Mudcat |

9.238 |

4.663 |

9.539 |

7.855 |

9.974 |

8.703 |

16 |

9 |

|

Tributaries |

11 AWG |

CFO II |

8.940 |

7.084 |

8.140 |

8.130 |

9.501 |

8.679 |

11 |

10 |

|

AVCable |

10 AWG |

CFO II |

9.075 |

5.209 |

9.586 |

7.976 |

9.707 |

8.668 |

13 |

11 |

|

River Cable |

Starflex |

CFO II |

8.759 |

7.522 |

9.002 |

8.429 |

9.000 |

8.657 |

6 |

12 |

|

Sound King |

12 AWG |

CFO |

8.467 |

4.974 |

9.694 |

7.681 |

9.988 |

8.604 |

20 |

13 |

|

Monster Cable |

Original |

CFO |

8.533 |

5.047 |

9.550 |

7.692 |

9.948 |

8.594 |

19 |

14 |

|

Monster Cable |

Navajo |

CFO |

8.068 |

5.429 |

9.625 |

7.644 |

9.930 |

8.558 |

21 |

15 |

|

Woods |

HD |

Mudcat |

8.281 |

5.380 |

9.156 |

7.589 |

9.979 |

8.545 |

23 |

16 |

|

Sound King |

V3 |

Mudcat |

9.238 |

3.597 |

9.711 |

7.561 |

9.955 |

8.518 |

24 |

17 |

|

Avic |

SC1100 |

CFO II |

7.687 |

7.839 |

8.949 |

8.076 |

9.130 |

8.498 |

12 |

18 |

|

Generic (Lowes) |

10/4 |

Mudcat |

9.275 |

3.551 |

9.604 |

7.532 |

9.923 |

8.489 |

25 |

19 |

|

Carol |

10/3 |

Mudcat |

9.352 |

3.431 |

9.115 |

7.393 |

9.978 |

8.427 |

26 |

20 |

|

Cardas |

Crosslink 1S |

CFO II |

7.495 |

7.298 |

9.225 |

7.899 |

9.119 |

8.387 |

15 |

21 |

|

Alpha |

85104CY |

Mudcat |

9.262 |

4.654 |

8.926 |

7.697 |

9.195 |

8.296 |

18 |

22 |

|

Sound King |

V4 |

Mudcat |

9.281 |

2.567 |

9.541 |

7.203 |

9.932 |

8.294 |

27 |

23 |

|

Carol |

12/4 T1 |

Mudcat |

8.339 |

3.560 |

9.362 |

7.086 |

9.978 |

8.243 |

30 |

24 |

|

Parts Express |

100-768 |

Mudcat |

6.771 |

4.755 |

9.499 |

6.863 |

9.994 |

8.115 |

33 |

25 |

|

River Cable |

Flexygy |

CFO II |

8.324 |

5.991 |

9.082 |

7.782 |

8.585 |

8.103 |

17 |

26 |

|

Generic (Lowes) |

12/4 |

Mudcat |

8.349 |

2.687 |

9.611 |

6.878 |

9.937 |

8.102 |

32 |

27 |

|

Stealth |

Premier II |

CFO |

10.000 |

5.678 |

9.842 |

8.574 |

7.204 |

8.026 |

5 |

28 |

|

Acoustic Research |

Speaker Cable |

CFO II |

8.986 |

2.447 |

9.898 |

7.140 |

8.991 |

7.880 |

29 |

29 |

|

Audience |

Maestro |

CFO II |

7.536 |

9.042 |

6.020 |

7.609 |

7.896 |

7.724 |

22 |

30 |

|

Goertz |

MI-2 Veracity |

CFO II |

8.524 |

10.000 |

1.000 |

6.965 |

8.710 |

7.663 |

31 |

31 |

|

Monster |

MCX-1S |

Mudcat |

3.903 |

5.288 |

9.158 |

5.765 |

9.820 |

7.387 |

34 |

32 |

|

Cardas |

SE 9 |

CFO II |

8.738 |

9.262 |

2.201 |

7.141 |

6.548 |

6.904 |

28 |

33 |

|

Empirical Audio |

Clarity 7 |

CFO II |

8.284 |

8.925 |

7.379 |

8.245 |

1.000 |

5.347 |

10 |

34 |

|

Stealth |

Fine Ribbon |

CFO |

1.000 |

1.000 |

10.000 |

3.430 |

7.969 |

5.246 |

35 |

35 |

TABLE 7 - Comparison of all Cables from the 3 Speaker Cable Face Offs

Editorial Note

The 1-10 scale ranks the overall score of the cable regarding technical and final rankings. The lower the #, the better the cable scored with respect to the test criteria, where the technical ranking is based solely on performance and the Final ranking also factors in value.

Conclusions

So, now that I went and did all this, who does it benefit? You I hope. For those with the most remote DIY capability, the path to a really thick, large diameter cable to impress the ego and neighbors, and performs as well as super high tech, expensive, snake oil laden (or even snake oil free), speaker cables is contained herein.

Hopefully, this will generate a lot of discussion, and I hope Mr. Escallier backs me up instead of insulting my mechanical engineering background. For my part, I think I'll try a blend of Cat 5 and the Sound King next.

P.S. Anybody want to buy some Monster MCX-1S speaker cables? I've got a couple of pairs to get rid of.

Audioholics would like to thank Thomas Goldsworthy for his Herculean efforts in writing this article, constructing the cables, and testing them. In future cable articles we will be implementing the Linear Interpolation method that Thomas established for ranking cables.