Master TVA30 Guitar Amp Review

- Product Name: TVA30 Guitar Amp

- Manufacturer: US Master

- Performance Rating:

- Value Rating:

- Review Date: March 20, 2012 22:45

- MSRP: $ 699 Combo + $45 shipping / $869 Head and Cabinet + $70 shipping (as reviewed)

- All tube 30 Watt Class A power amp with 4-EL84/6BQ5 and 3-12AX7 preamp tubes

- 2 channels - Clean and Drive (High Gain), footswitchable.

- Controls - Clean Volume, Drive Gain, Drive Volume, Channel Switch, LED Channel Indicator, Boost (affects both channels), Treble, Middle, Bass, Reverb, Effects Level, Standby, Power.

- Rear Panel - Effects Send (Pre-amp Out), Effects Return (Power Amp In), Stereo Footswitch Jack (reverb and channel switch), 2 Speaker Outputs, Speaker Impedance Selector (4 or 8 ohm), Power Cord and Fuse Assembly

- Wiring - Point-to-point, hand wired, shielded wiring for internal signal paths, no connectors internally except to connect to the reverb tank (uses RCA connectors).

- One year limited warranty, 90-days on speaker and tubes.

- 5 day return policy for auditioning the amp.

Pros

- Amazing value considering 30 Watts and features

- Two channels – clean and high; foot switchable

- Hi and Low inputs

- Self-Biasing tube circuitry

Cons

- Speaker driver linearity could be improved

- Spike in low midrange response could not be resolved using tone controls on amp head

- Very low volume bass response

- No indicator light for Standby switch

- Reverb not very dynamic

- Power tube connectors poorly supported, directly mounted to PC boards and only one tiny set screw

Master TVA30 Introduction

When searching for the perfect budget minded Guitar Amp, the factory direct US Master’s TVA30 rivals most of what’s out there in the local retail outlets. Although I’ve been playing guitar for nearly 30 years, I’ve spent the past 6 months obsessing on upgrading my equipment in order to stretch the envelope and to define a unique, out of the ordinary sound. I already had two custom made electric guitars with what I consider, very high end active pickups from both Bartolini and EMG, each guitar also having Piezo Electric pickups with separate output for running through a second acoustic guitar amp. Both guitars have through body necks for maximum sustain, one being made in California, the other right here in Orlando.

I’ve most recently gone through countless effects pedals to further define

that unique sound. From distortion to chorus to synthesizers and

even polyphonic octave generators, I’ve tried tons and settled for

only the ones that I found to be best for that signature sound. Most

recently, I turned to improvement of my guitar amplifier. This time,

I knew I wanted to go all analog and have the best tubes and

electronics available, my only limitation being budget. I also

wanted to limit the weight because I needed my new amp to be portable

without breaking my back. I held very little interest in going

mainstream knowing that these mass produced products would sound

exactly like nearly everyone else playing today. So I started my

website search with terms like, “Customer Guitar Amp,” “Handmade

Guitar Amp,” “American Made Guitar Amp” and so on. I was

actually surprised to see the number of high end guitar amps that are

out there. Regretfully, none of them see the light of day at the

Nationwide Music Stores, and some only sell direct, meaning I didn’t

have an opportunity to listen unless I purchased. What I also

noticed was that the vast majority of these uncommon amplifiers were

in the thousands of dollars, and after contacting many, some had

waiting lists several months long. There was; however, an exception

to this and it caught my immediate attention, warranting further

investigation.

most recently gone through countless effects pedals to further define

that unique sound. From distortion to chorus to synthesizers and

even polyphonic octave generators, I’ve tried tons and settled for

only the ones that I found to be best for that signature sound. Most

recently, I turned to improvement of my guitar amplifier. This time,

I knew I wanted to go all analog and have the best tubes and

electronics available, my only limitation being budget. I also

wanted to limit the weight because I needed my new amp to be portable

without breaking my back. I held very little interest in going

mainstream knowing that these mass produced products would sound

exactly like nearly everyone else playing today. So I started my

website search with terms like, “Customer Guitar Amp,” “Handmade

Guitar Amp,” “American Made Guitar Amp” and so on. I was

actually surprised to see the number of high end guitar amps that are

out there. Regretfully, none of them see the light of day at the

Nationwide Music Stores, and some only sell direct, meaning I didn’t

have an opportunity to listen unless I purchased. What I also

noticed was that the vast majority of these uncommon amplifiers were

in the thousands of dollars, and after contacting many, some had

waiting lists several months long. There was; however, an exception

to this and it caught my immediate attention, warranting further

investigation.

Master TVA30 Guitar Amp Introduction

The Decision

US

Masters was known mainly for their US Made Guitars and Basses with

various models to suite most budgets. What they may not have been

known for is being a supplier of guitar amps, specifically the TVA30.

This model comes either as a combo or head and cabinet retailing for

$699 and $869 respectively. Upon review of their website, it was

easy to notice that they were very proud of the components used in

their amplifiers and the quality in which the cabinets were built.

They were one of the few websites I’ve found that showed specifics

on the amp build including torodial power transformer, output

transformer, wiring methods, reverb springs, tubes, and nearly

everything else. They even devoted a section of their website to

help the novice understand amplifier terms. I was impressed with

their story and more impressed with the price. My only hesitation

was the fact that the amp was manufactured in China. For days, I

continued my search for my new prize amp but was unable to find what

I believed to be a close match with 30 Watts, 12” Driver, Mid /

Treble / Bass Controls, Hi and Lo inputs, overdrive, effects loop

send and return…..for less than $2,000. I just did not have the

budget, and not being a professional musician, could not justify

spending that much money. Furthermore, nearly all other amps in this

price range were also made in China. So I decided to read as many

reviews as possible on the TVA30 and other amps, only to learn that

most “reviews” were nothing more than commentaries in blogs and

forums while the rest were on websites of stores selling the actual

equipment. Though lacking technical merit, I quickly learned that

the blogs and forums were light up with nothing but positive feedback

for the TVA30. Then, when reviewing US Master’s website, I learned

that they offered a 5 day return policy. I figured at that point

that there was nothing to lose and everything to gain by finding a

“Boutique” non-mainstream guitar amp for under $1k. I called US

Masters, ordered and within a matter of minutes, my new found amp was

on its way to my home.

US

Masters was known mainly for their US Made Guitars and Basses with

various models to suite most budgets. What they may not have been

known for is being a supplier of guitar amps, specifically the TVA30.

This model comes either as a combo or head and cabinet retailing for

$699 and $869 respectively. Upon review of their website, it was

easy to notice that they were very proud of the components used in

their amplifiers and the quality in which the cabinets were built.

They were one of the few websites I’ve found that showed specifics

on the amp build including torodial power transformer, output

transformer, wiring methods, reverb springs, tubes, and nearly

everything else. They even devoted a section of their website to

help the novice understand amplifier terms. I was impressed with

their story and more impressed with the price. My only hesitation

was the fact that the amp was manufactured in China. For days, I

continued my search for my new prize amp but was unable to find what

I believed to be a close match with 30 Watts, 12” Driver, Mid /

Treble / Bass Controls, Hi and Lo inputs, overdrive, effects loop

send and return…..for less than $2,000. I just did not have the

budget, and not being a professional musician, could not justify

spending that much money. Furthermore, nearly all other amps in this

price range were also made in China. So I decided to read as many

reviews as possible on the TVA30 and other amps, only to learn that

most “reviews” were nothing more than commentaries in blogs and

forums while the rest were on websites of stores selling the actual

equipment. Though lacking technical merit, I quickly learned that

the blogs and forums were light up with nothing but positive feedback

for the TVA30. Then, when reviewing US Master’s website, I learned

that they offered a 5 day return policy. I figured at that point

that there was nothing to lose and everything to gain by finding a

“Boutique” non-mainstream guitar amp for under $1k. I called US

Masters, ordered and within a matter of minutes, my new found amp was

on its way to my home.

First Impressions

The

TVA30 cabinet and head arrived only three days after ordering.

Without hesitation I carved my way into the boxes quickly looking at

the back of the amp head to see firsthand, what the hype was

regarding the electronics. Normally, I wouldn’t post a

Manufacturer’s marketing pictures in a review; however, after

studying so many amps, I found their claims and these pictures to be

valid and justifiable. This amp head was clearly a beast among the

norm.

Other noteworthy finds included the metal reinforced, self-aligning indents on the speaker cabinet for a perfect fit amp head to the closed back speaker cabinet. The nice thing about having this area reinforced is that it prevents wear and tear if you are one of those users who move the amp head on and off a great deal between transporting to gigs. The disadvantage was noticed when we started sending controlled frequencies through the amp during speaker measurements. We quickly found resonance frequencies in which we could actual hear ringing noises.

I noticed that Master used “industry standard” handles and clamps for both the speaker cabinet and head. Below are photos of what happens over time with this configuration. For the life of me, I can’t understand why this design is still used by so many manufacturers. As you will notice in the picture, the handle coating binds into the metal edge of the clamp. Eventually, it starts to tear the handle as shown below.

This may be more of a personal preference than actual flaw; however, I would like to have seen the “STANDBY” back light yellow when on. Red for power and yellow for standby is very common and actually helpful when you are playing in a poorly light venue, as I often do. Such an addition would likely not add much to their costs and would have matched well with the red light for power.

Master TVA30 Guitar Amp Listening Impressions

I

eagerly plugged in my custom Carvin SC90 modified with EMG 89XR neck

pickup, EMG 81TWX bridge pickup and Ghost Tune-O-Matic Piezo-Electric

bridge. Switched to my common sweet spot, using both bridge and Neck

in single coil mode, plugged into the “Hi” input and using the

“Clean” channel, I hit my first open G, C and D chords with a

light, steady strum. Right away, I noticed the Amp provided a

liveliness and spunk to my guitar tone that I hadn’t heard in many

former guitar amps. Highs were clear, the sound was snappy and I was

shamefully able to hear my fingers manhandling the strings clearly

and crisp. I knew I would be in trouble as this amp would require me

to clean up my playing. I then decided to switch to the “Drive”

channel and worked my way from little to full over drive distortion.

My first impression was amazement at how natural and long sustaining

the overdrive of this amp sounded. I was so moved by the tone that I

felt compelled to compare it to my Visual Sound Jekyll and Hyde

distortion pedal, which I’ve already put to the test verifying that

it was a great sounding distortion pedal when compared to many others

I’ve reviewed. I switched back to a comparable speaker volume

through the clean channel and engaged the dark side of my Jekyll and

Hyde. It sounded simply amazing as well, though not quite as lively.

The advantage of using a distortion pedal through the clean channel

was that it doesn’t overdrive the tubes thereby eliminating

background noises such as hiss. In a sterile environment such as my

living room or a studio, this hiss can be somewhat distracting,

though as was the case with the TVA30 in overdrive, it was very

minimal. My personal favorite and newfound tone was the TVA30 in

overdrive. It produced a slightly more lively and natural distortion

sound than my Jekyll and Hyde could emulate after playing with all

the settings. A great tone for a gig.

I

then switched my guitar to the Ghost Piezo bridge. I have this pickup

wired as a separate output on my guitar so as to allow me to run it

into a separate acoustic guitar amp such as my SWR Strawberry Blonde.

I also have it wired with an optional blend into the electric output

so I can mix it with the EMGs and create a hollow body guitar tone.

I was pleasantly surprised to hear high frequency tones of the

Piezo-electric through a single 12” speaker. Though not quite as

distinct as my Strawberry Blonde which also includes a tweeter, it

was sufficient enough to glean the tonality of an acoustic guitar.

In comparison to the Strawberry Blonde though, there was a noticeable

drop in bass punch.

then switched my guitar to the Ghost Piezo bridge. I have this pickup

wired as a separate output on my guitar so as to allow me to run it

into a separate acoustic guitar amp such as my SWR Strawberry Blonde.

I also have it wired with an optional blend into the electric output

so I can mix it with the EMGs and create a hollow body guitar tone.

I was pleasantly surprised to hear high frequency tones of the

Piezo-electric through a single 12” speaker. Though not quite as

distinct as my Strawberry Blonde which also includes a tweeter, it

was sufficient enough to glean the tonality of an acoustic guitar.

In comparison to the Strawberry Blonde though, there was a noticeable

drop in bass punch.

I spent the good part of the day switching effects pedals, switching guitars, adjusting settings and seeking every plausible combination I could come up with. The entire time I was pleased with the overall tone of the amp; however, I did feel that the low mid-range frequency was a bit more enhanced than I desired, even with the “Middle” tone knob turned to near zero. I longed for a bit more balance and certainly a bit more obvious bass. This was especially true when switching to the Electro-Harmonix Harmonic Octave Generator (HOG). The HOG is a wonderful pedal that among other features provides an accurate representation of guitar tones with separate selection knobs for one and two octaves down, one, two, three and four octaves up and thirds and fifths. I played through the scales from low to high and found it could produce some of the bass at the lower octaves, but I definitely wished it was more pronounced and punchy. As comparison, when using the same pedal on the Strawberry Blonde, it’s as though I turned on a high powered home theater subwoofer; whereas, the TVA30 was only able to play the tones, but missed the much desired dynamics. When using the higher frequencies, the snappy punch of the speaker was pronounced making the pedal sound amazing. Adjusting the HOG correctly actually allows the musician to emulate an organ sound, and the TVA30 certainly had the mids and highs to make it very believable. Through the spectrum of settings, I still noticed the low mids being more aggressive than desired.

I then went on through the range of Reverb settings. I found the Reverb to be a nice touch with a very natural sound, though my only comment was that at its maximum setting it did not perform as dynamic as other amps I’ve heard. Though, this didn’t concern me as I really don’t use much Reverb when considering the armament of pedals I have at my disposal.

Master TVA30 Guitar Amp Review Cabinet

We opened the back end of the speaker cabinet to do some exploration. The cabinet was had a very impressive in build quality. The dovetail joints were barely visible and the cabinet was constructed of ¾” thick plywood. The speaker was secured with only four machine screws with flush mount metal inserts. I would have preferred more to help prevent resonant vibrations. I was also a bit unimpressed by the very thin gauge speaker wire.

Inside the Master TVA30 Cabinet

The Chassis and Electronics

The electronics and hand wiring throughout the amp head are very high quality. This all tube, 30 watt class A power amp comes armed with four EL84/6BQ5 power tubes and three 12AX7 preamp tubes. No solid-state devices are in the signal path nor are any used for creating the rich overdrive distortion. Worth mentioning, even though it is not published by US Masters, is that the amp is self-biasing. This means that there is no need to recalibrate after changing tubes. Though, given the retail price of this amp, there’s bound to be some economic based decisions. For example, the tubes are made in China. Some would argue that the quality of their tubes is not near that of Russian; however, neither is the price. But there are a few areas that I deem unforgivable. For example, tubes are considered a maintenance item, meaning they need to be changed often (depending on usage). That said I would have expected a much more robust method of mounting the power tube connectors. As you can see in the pictures below, these connectors are mounted directly to the board with only one, very small set screw securing it. This becomes problematic when placing a new tube in the connector as the force required to secure it puts stress on the board while it flexes on the hinged design of the single set screw. This is not the same for the pre-amp tubes; however, as their connectors are more robustly secured with two screws and not mounted directly to the board.

Other items to note was that the reverb assembly was mounted with the RCA connectors facing the front of the amp. This made it impossible to remove the chassis without also removing the front cover in order to release the connectors. Prior to putting the chassis back in, I was sure to turn the reverb assembly in a more convenient orientation having the connectors pointing towards the back. Another annoyance was with regard to the “captive” nuts used to secure the chassis to the cabinet.

As you can see in the picture of the chassis, it is fabricated from sheet metal, therefore has inherent flexibility, thus making it impossible to align all the screws when placing it back into the cabinet. The poorly designed captive nuts are not forgiven with misalignments. If they are slightly misaligned with the clearance hole, it is far too easy to accidentally push them out and directly into the chassis. For obvious electrical reasons, it’s not a good idea to leave these electrically conductive nuts inside the electronics. It took me five times of mounting and removing the chassis before I was able to finally get all the screws back in without having or more pop out. This too I’d call a maintenance nightmare.

Master TVA30 Guitar Amp Measurements and Analysis

Having done all we could with my listening pleasure, we turned to some objective measurements. Using the Audio Precision APx585 HDMI Audio Analyzer, we tested the amplifier’s power, frequency output, and total harmonic distortion as seen in the following measurement results.

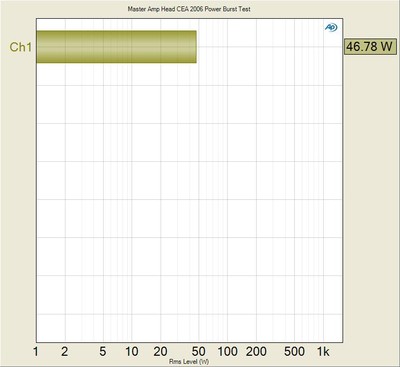

Master TVA30 Dynamic Power Output (8 ohms)

This measurement shows a CEA 2006 Peak Power Output, which is a dynamic power rating closely resembling musical peaks. According to this measurement, the amplifier’s peak power output is 46.78 Watts when driving an 8 ohm load which is what the stock speaker for this unit was rated at.

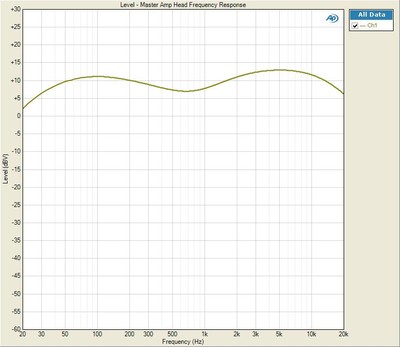

Master TVA30 Frequency Response (8 ohms)

This measure shows the frequency response of the amplifier under an 8-ohm resistive load. As you can see, it is not very linear, as expected for a tube amplifier. Some may argue that it is the non-linearity of the amplifier that defines its signature sound.

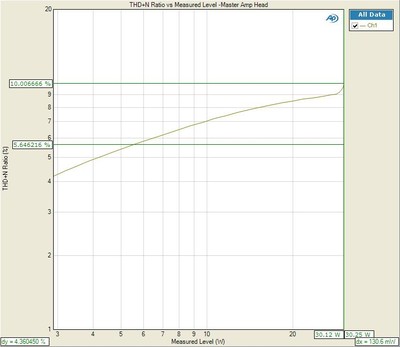

Master TVA30 Power vs Distortion (8 ohms)

This graph shows that lowest THD of the amp is 4%. It also verifies the manufacturer’s spec of 30 Watts with a THD of 10%. We suspect the high distortion is common with tube guitar amplifiers; however, future testing of other amplifiers will help us verify this as fact.

Speaker Measurements

Prior to pulling the speaker for examination, we conducted a near field frequency response measurement in 1/12dB increments at three different power levels. All tone controls were set to flat.

Set up of speaker cabinet frequency response testing was with near field microphone from our LMS measurement system. The home theater room had acoustic treatment. The amp head is separated to eliminate the resonance vibration discussed earlier.

Frequency Response of Master Stock Driver Loaded in the Cabinet at various power levels

There

are two spikes seen on this graph, both of which are due to resonance

frequencies from a vibrating cabinet at 100Hz and most likely the

speaker basket between 2kHz to 3kHz. Aside from that, the speaker’s

flattest response was at the lowest power setting. Once moderate

volume was applied, the speaker had a large hump response that went

out until about 200 Hz. This coincides with what I heard regarding

the low-mids being a bit over emphasized. There’s another hump

around 1.5kHz which is likely attributed to the speaker as well.

Overall, the system is not linear, but considering that the amp

output is not linear, it wasn’t a surprise.

There

are two spikes seen on this graph, both of which are due to resonance

frequencies from a vibrating cabinet at 100Hz and most likely the

speaker basket between 2kHz to 3kHz. Aside from that, the speaker’s

flattest response was at the lowest power setting. Once moderate

volume was applied, the speaker had a large hump response that went

out until about 200 Hz. This coincides with what I heard regarding

the low-mids being a bit over emphasized. There’s another hump

around 1.5kHz which is likely attributed to the speaker as well.

Overall, the system is not linear, but considering that the amp

output is not linear, it wasn’t a surprise.

After

the measurements, I removed the speaker for further examination. I

believe that this was the low point design of the entire Master TVA30

Guitar Amp as this speaker was a rather run of the mill design. The

basket was thin sheet metal with very little bracing. The paper

material was so pliable that you can almost shape mold your finger

tip around it. Other speakers used in similar speaker cabinets

appear to be much more robust than that offered here as shown in the

pictures below.

Eminence DeltaPro with Cast Aluminum Basket Master, Weber Michigan and Eminence DeltaPro

There was virtually no comparison between the Master speaker to the Eminence DeltaPro-12A. The DeltaPro-12A is a mechanical giant weighing in at 18 lbs and including a cast aluminum basket and 2.5” diameter voice coil. This beast can be found through reputable on-line stores for around $120. The picture on the right shows a notable difference in the size of the voice coils between the Weber Michigan and Delta Pro when compared to the much smaller size Master. In all cases, the paper cones were considerably stiffer as was the surrounds, than that of the Master speaker. In our next review, we intend to compare through listening tests and measurements, three other speakers including the Weber Michigan, Weber California and Eminence DeltaPro. In addition, we will be doing the same with high quality Russian made Tubes.

Master TVA30 Guitar Amp Conclusion

The Master TVA30 is a great option for someone looking for an economical, non-commercial guitar amp that provides great performance and useful options. The amp head appears to be built very well and is fully capable of performing better than anything in its price class. Though I pointed out some mechanical shortcomings, these do not take away from the overall tone and performance of the amp. For the price, it’s nice to see two channels, one for clean and one for over drive, and an effects loop. The system also comes with a two button foot controller to help you switch between channels with ease. When considering that it retails for $869, there are very little options that can compete. Though, if you are an audio fanatic like me, it may be worth springing anywhere between $90 to $120 for a different speaker from companies like Weber, Eminence or Celestion. Another investment would come when the china made tubes eventually wear. At that time, I’d consider swapping them for something with a more robust build. A great place to buy is www.thetubestore.com. I’ve found their pricing competitive and their level of technical understanding to be far better than other on-line stores or guitar centers. Even with these investments, you are still only around $1,000 for a great combo that is portable and very well made.

US

Master TVA30 Head and Cabinet Scorecard

MSRP:

$869 (as reviewed)

©

2010 Masters Design, U.S. Masters Guitar Works is a product of Young

Guitars Inc.

2324

Pinehurst Dr. Unit B

Middleton,

WI 53562

Phone: 877-716-0000

Email: sales@youngguitars.com

About US Masters

US Masters is known for crafting made in the USA Guitars and Basses using fine woods and modern CNC equipment to keep them affordable. They engineered a high quality guitar amplifier to extend their product offerings, and have it fabricated in China in order to keep it under $1,000. US Masters provides excellent customer support and is a reliable source to buy direct.

The Score Card

The scoring below is based on each piece of equipment doing the duty it is designed for. The numbers are weighed heavily with respect to the individual cost of each unit, thus giving a rating roughly equal to:

Performance × Price Factor/Value = Rating

Audioholics.com note: The ratings indicated below are based on subjective listening and objective testing of the product in question. The rating scale is based on performance/value ratio. If you notice better performing products in future reviews that have lower numbers in certain areas, be aware that the value factor is most likely the culprit. Other Audioholics reviewers may rate products solely based on performance, and each reviewer has his/her own system for ratings.

Audioholics Rating Scale

— Excellent

— Excellent

— Very Good

— Very Good

— Good

— Good

— Fair

— Fair

— Poor

— Poor

| Metric | Rating |

|---|---|

| Build Quality | |

| Appearance | |

| Treble Extension | |

| Treble Smoothness | |

| Midrange Accuracy | |

| Bass Extension | |

| Bass Accuracy | |

| Dynamic Range | |

| Performance | |

| Value |