Audiophile Power Cords - Do they really make a difference?

We are sometimes asked our opinion of exotic power cords, and have met more than a few people who have laid out some serious investment to have what they see as the very best sort of cord running from the wall socket to the IEC socket on the back of a power amp or CD player. At our company, Blue Jeans Cable, we don't sell power cords, and apart from the possibility that one of these days we may sell some short-length IEC cords for people who like to have tidy rack installations, it's not likely that we ever will. Why? Well, read on to find out.

The Signal Chain

All of the audio and video cables we sell have one thing in common, whether they are made for audio or for video, digital or analog: they're all in the signal chain, carrying actual audio and video signals from device to device. Too much is often made of the impact of cable attributes upon video and audio quality, but it's fair to say that any cable in the signal chain, carrying signals, has at least the potential to have an impact upon the quality of your system's audio or video output.

Power cables are a different matter. At no point in use do they carry signals--they simply convey power from your home's main supply to your devices' power supplies. This is important, to be sure, and without a power cable your system isn't going to do very much at all, but the question of course is not whether the cable is essential but whether there are differences in performance between reasonably-well-constructed power cords, and on that question we have to say that the answer is simply "NO."

What Matters in a Power Cable?

You'll note that we said "reasonably well-constructed" power cords, and there is a reason behind that. It is possible, under some circumstances, to cause a system to behave suboptimally by using a poorly-designed power cable, but the main consideration at work here is simply wire gauge, and in such a circumstance all one really needs to do is increase the gauge of the cable. So, while a power cord upgrade in such a situation may indeed be advisable and helpful, it's likely to be a five or ten dollar solution, not a five-hundred-dollar or higher solution.

To see how gauge can be important, let's talk about what a power cable does, and about what the power supply it feeds does.

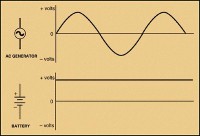

Most

circuits in use in consumer electronics run on Direct Current (DC) voltages,

which can run anywhere from a couple of volts up to, in the case of tube equipment,

hundreds of volts. Ideally, these DC

circuits should be fed a constant, clean, level voltage. What comes down the street, through your

house's service entrance, and to your wall socket, however, is not DC but AC,

Alternating Current. AC power supplied

to your home changes its voltage dramatically from moment to moment, and

ideally, presents a sine wave which cycles from zero, to negative, through zero

to positive, and then back to zero, sixty times a second in the USA and 50

times a second in most other countries. Incidentally, although household current in

the US is fed at what we call "110 volts," that's the RMS voltage;

the voltage actually cycles from about 170 volts positive to 170 volts

negative.

Most

circuits in use in consumer electronics run on Direct Current (DC) voltages,

which can run anywhere from a couple of volts up to, in the case of tube equipment,

hundreds of volts. Ideally, these DC

circuits should be fed a constant, clean, level voltage. What comes down the street, through your

house's service entrance, and to your wall socket, however, is not DC but AC,

Alternating Current. AC power supplied

to your home changes its voltage dramatically from moment to moment, and

ideally, presents a sine wave which cycles from zero, to negative, through zero

to positive, and then back to zero, sixty times a second in the USA and 50

times a second in most other countries. Incidentally, although household current in

the US is fed at what we call "110 volts," that's the RMS voltage;

the voltage actually cycles from about 170 volts positive to 170 volts

negative.

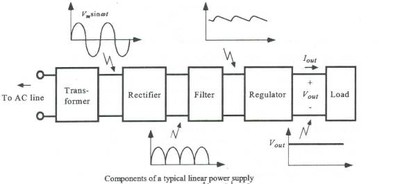

Quite obviously, DC circuits, with their demand for clean, stable voltage, cannot be powered just by plugging them in to the AC power that comes to your wall socket. Accordingly, devices which need DC get it through a built-in power supply which accepts the AC from the wall and converts it to the desired voltage or voltages. The classic design for a power supply, and still the dominant one, consists of a transformer, a rectifier, and a filter; many modern supplies add to this a voltage regulator.

Power comes in through the socket and enters the transformer, which is typically an iron core with coils of copper wire wound tightly around it. One rather odd thing about a transformer is that, to look at how it's made, one would think that the power couldn't get out of the wall and into the circuits, because the wire that runs the power from the wall into the transformer simply makes a series of turns around the transformer core and then leaves for the wall, with no interconnection to the other wires on the transformer core. Thanks to the property of inductance, however, what is actually happening is that energy running through this winding of the transformer induces a field around the other windings, and causes current to flow in them. The result is that the AC from the wall is turned into AC of whatever voltage or voltages are required.

Block Diagram of Basic Power Supply Circuit

Now, this is still AC, and unsuitable for powering DC circuits, but we've stepped the voltage up or down to the level needed. The next step is to run it through a rectifier, which typically is a set of diodes, which act as one-way valves for electrical flow. By the right configuration of diodes, e.g., what is commonly known as a "bridge rectifier," one can switch the connections around in such a way as to "flip" the negative voltages in each cycle and turn them into a positive voltage, or vice versa, as required. Instead of a voltage which fluctuates from negative through zero to positive and so on, we now have a voltage which fluctuates from positive to zero, then zero to positive, and so on.

The problem with rectified AC is that our DC circuits still won't work well on it, because they are designed to take an input of a constant voltage, not a continually fluctuating one, and audio circuits in particular will sound awful if we feed them a power supply that carries a loud, low buzz like this. Somehow we've got to smooth these fluctuations out, and this is where filtration comes in. A power supply will typically have a filter capacitor, which allows power to store up during peak voltages and be drawn down when the supply voltage drops, and may also have chokes, which are large, heavy coils whose inductance discourages the rate of current flow from fluctuating. To this may be added a voltage regulator, which typically is a solid-state device designed to prevent the voltage from exceeding a certain value. Assuming that the design of the power supply has been done right, by this time we have taken the nasty up-and-down, humming wall current and turned it into nice, usable, clean, quiet DC at whatever voltage, positive or negative, our circuits require.

When Power Cords Go Bad

There's not a lot that can go wrong with a power cord, but there's one thing in particular which can be of importance. An undersized power cord (that is, a power cord of inadequate gauge for the current running through it) can be dangerous, because it can overheat and start a fire. Apart from being dangerous to life and limb, interestingly, an undersized power cord can, under just the right sort of conditions, have an adverse impact upon audio quality as well.

We ordinarily think of the voltage which appears at the input of a power supply as being the same as the voltage supplied to the home, but this is not quite actually the case. Unless your home is wired with superconductors, every foot of wire along the way presents a bit of resistance, which results in some of the current which flows in that wire being turned into heat. The circuit really begins with this wire "resistor" on the live line, then the load of the device's power supply, and then another wire resistor on the neutral line back to your service panel. For most loads, these resistances in the wire are insubstantial and can be ignored. However, in accordance with Ohm's law, the energy traveling in the circuit is consumed by the circuit's elements in proportion to their resistance; a high-impedance, low-power load such as a cell-phone charger consumes almost all of the small amount of power flowing in the circuit, but a low-impedance, high-power load like a space heater, by virtue of its low internal resistance, causes a higher proportion of the power in that circuit to burn up in the wires that feed it. When that happens, another property of the circuit varies: the voltage across those power supply input terminals. If the supply voltage is 110 volts, and the device presents a resistance of, say, ten ohms while the wire presents a resistance of one ohm, one eleventh of the power supplied is burning up in those supply wires and the voltage across the power supply terminals will be not 110 volts, but 100 volts. As that voltage drops, the voltages coming out of the other end of the power supply transformer drop proportionally, and this sort of thing can cause some trouble.

The power supply of an amplifier relies upon the filter capacitor to hold enough charge to provide the desired voltage at the power supply output when the incoming rectified voltage is at a low point, and so the capacitor is drawn down when the rectified voltage is low and charged up when it is high. Some things can draw that power faster than others, and heavy bass is one of those things. Let's say that we have a badly undersized power cord, and are playing bass-heavy music on a power amp. The bass draws down the filter capacitor, and the power supply draws current to try to replenish that charge; however, the more current the supply demands, the lower its impedance, and with an undersized power cord, this means that the supply voltage drops. If the voltage drop is strong enough, the filter capacitor will not fully charge up on the next cycle of high voltage, and this means a reduced supply voltage to the amplifier circuits. This phenomenon will occur in direct relationship to how much of this loud bass is being produced, and what does that mean? The bass note is now modulating the entire output of the amplifier which can in turn increase intermodulation distortion.

Now, this is an unusual scenario. There are any number of reasons why, in any particular system, it may not happen. The filter capacitor may be amply sized; the power cord may be of perfectly adequate gauge; the power supply may be delivering a slightly high voltage into a regulator anyhow and so the voltage fluctuations are stopped at the regulator. But if the factors are all right, it is indeed possible for a power cord to have a negative impact upon sound quality.

But what would fix this? The answer, of course, is simply that a power cord of adequately large gauge would fix it, if anything will. If that won't fix it, the problem is in the power supply design and no power cord, of any sort, is going to help. No exotic design, full of silver conductors, braided wires, shielding, Teflon, or what-have-you, is going to help resolve this sort of problem any better than any other cord of similar gauge because the one and only problem is that the resistance of the cord is too high.

What is Wire / Cable Gauge (AWG)?

Wire gauge is a measurement

of the size of the wire based upon its cross-sectional area; although some

sources will show metric wire gauge sizes, the usual method of notation in the US is "American Wire Gauge,"

or AWG. In AWG, the size of a wire is

expressed on a base-ten logarithmic scale where the larger the AWG, the smaller

the wire is--so that, for example, a 30 AWG wire is ten times as large in

cross-section as a 40 AWG wire, and one-tenth as large as a 20 AWG wire.

Wire gauge is a measurement

of the size of the wire based upon its cross-sectional area; although some

sources will show metric wire gauge sizes, the usual method of notation in the US is "American Wire Gauge,"

or AWG. In AWG, the size of a wire is

expressed on a base-ten logarithmic scale where the larger the AWG, the smaller

the wire is--so that, for example, a 30 AWG wire is ten times as large in

cross-section as a 40 AWG wire, and one-tenth as large as a 20 AWG wire.

Since resistance, at DC, is directly proportional to wire cross-sectional area, the AWG scale likewise tells us that a 10 AWG wire will have one-tenth the resistance of a 20 AWG wire, and so on. Since resistance converts electrical energy to heat energy, the size of a wire determines, for a given electrical flow, how much heat the wire will have to dissipate, and this obviously has a direct bearing upon electrical safety because as the wire becomes quite hot, the insulation will deform, melt, or even combust--and, if we crank the current high enough, the wire itself will melt. Electrical codes, like the NEC ("National Electrical Code," in use in most USA jurisdictions), limit how much current can be carried in a wire of a given size because the failure of wire or of its insulation increases the hazards of fire and shock.

Our current discussion and the tables below deal with copper wire because copper is overwhelmingly the most common material used in power cords. Silver is marginally more conductive but is problematic when used as wire because it is somewhat brittle, cannot be annealed, and is quite expensive; other metals like aluminum are sometimes used but are less conductive (i.e., more resistive) and therefore need to be used in larger gauge sizes.

For detailed analysis on cables, read: What Matters Most in Speaker Cables?

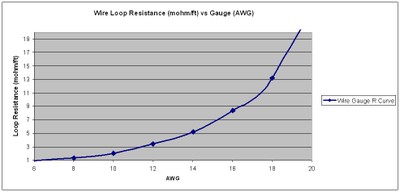

Cable Resistance vs Gauge

As you can see the lower the cable gauge, the less resistive loss a power cable will cause. Now, as noted above, how important resistance is will depend heavily upon the load being driven, with a small high-impedance load and its low current draw placing very little demand on the cord, while a large low-impedance load will cause a large current flow and consequently a comparatively high resistive loss in the power cable.

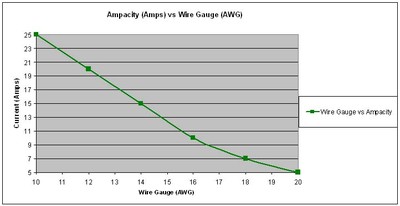

People sometimes make the mistake of thinking of the power cable as limiting the current available to the device it feeds in an absolute sense--that is, as though a power cord designed to take 14 amps will take 14 amps and no more. In fact, the limitations upon amperage, often referred to as "ampacity," which we see marked on products or in spec sheets are not absolute limits--it is, indeed, possible to push a tremendous amount of current through a 14 AWG wire, up until the point when the heat generated melts the wire and breaks the circuit (the "fusing" current). What statements about "ampacity" really mean is that, according to some set of criteria established by code or by an organization such as UL, a given current flow is considered safe for a certain gauge of wire. Going to a larger gauge (smaller AWG number) will always reduce resistance, and will reduce the voltage drop between the wall socket and the power supply input, but in most cases this will be of no consequence if the power cord is adequately sized relative to safety considerations. Exceptions would include cases where a power cord is abnormally long (e.g., a power amplifier is being run on a 100-foot extension cord of minimum acceptable gauge; the cord is safe because it can easily dissipate the heat given off over its entire length, but the resistance of the cord is abnormally high because of its great length) or where a power supply has been poorly designed and is intolerant of small voltage drops.

The ampacity limits based upon safety concerns, for flexible power cords, are set out in the NEC and, for most cord types, are as indicated per the graph below:

Ampacity vs Gauge

These go higher still, but since most branch circuits in residential installations are overcurrent-protected at no more than 20 amps, they become of little relevance to consumer audio and video (important, though, if you're installing a clothes dryer!). These AWG sizes should be adequate, in the vast majority of applications, not only to maintain safety but also to provide adequate current to prevent any adverse impact upon audio and video quality.

Electrical Safety

One important way in which power cords differ from audio and video cables is that power cords carry hazardous voltages and currents. An audio interconnect might carry a one-volt signal, while your power main carries (in the US) more than a hundred volts of AC, and is capable of delivering lethal current at that voltage. Not only is the power hazardous to human life directly, but it poses a very real potential fire hazard--shorts, arcing, and excessive heat all can lead to a house fire, and it's very important to be sure that a power cord is safely designed.

UL listing is probably the best reference a power cable can have; it indicates that the cable not only is made from appropriate materials, but that the assembly itself, as an integrated whole, has been shown to comply with UL standards for fire safety. There are many exotic power cords that don't carry a UL listing. Some may meet UL standards but the manufacturer has not wanted to invest in UL testing; but others are not tested simply because they would not meet the applicable standards. Sometimes the problems are inherent in the design. For example, it's hard to build a shielded power cord which meets UL standards because shielding tends to reduce heat dissipation.

Fire kills, and shock kills, too. For these reasons we strongly recommend the use of UL-listed power cords.

What About These Claims for Exotic Cords?

It's hard to characterize all of the strange claims associated with power cords, and some of the claims are so vague that they're hard to understand, much less critique. The one which is commonly made and which comes closest to making just a bit of sense is noise rejection, so we'll talk about that here.

Improved Noise Rejection

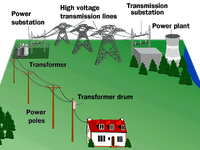

It's often said that a high-end power cord will help

reject noise, keeping a system's "noise floor" low and therefore

providing a cleaner sound, by virtue either of superior shielding or twist

geometry. This sort of claim ignores

two critical considerations. First, the

power cord simply is not often a source of noise introduction, and if the amp

has a properly-designed power supply it should be well-nigh impossible to get

noise into the system through the power cord.

The transformer, in particular, with its extremely high inductance,

tends to act as a strong choke against high-frequency noise. Second, even if the few feet of power cord

between the wall and amp were acting as an antenna to pick up induced noise,

superior noise rejection in those few feet would do little to no good when the

installed wiring in the wall, back through the service panel, and up the street

to the next transformer in the line is not shielded against noise at all. In other words, there may be hundreds of feet

of exposed power line between that last transformer and your power supply;

shielding, twisting, or otherwise treating the last six feet of cable for superior

noise rejection makes very little difference to the exposure of the line to

noise.

It's often said that a high-end power cord will help

reject noise, keeping a system's "noise floor" low and therefore

providing a cleaner sound, by virtue either of superior shielding or twist

geometry. This sort of claim ignores

two critical considerations. First, the

power cord simply is not often a source of noise introduction, and if the amp

has a properly-designed power supply it should be well-nigh impossible to get

noise into the system through the power cord.

The transformer, in particular, with its extremely high inductance,

tends to act as a strong choke against high-frequency noise. Second, even if the few feet of power cord

between the wall and amp were acting as an antenna to pick up induced noise,

superior noise rejection in those few feet would do little to no good when the

installed wiring in the wall, back through the service panel, and up the street

to the next transformer in the line is not shielded against noise at all. In other words, there may be hundreds of feet

of exposed power line between that last transformer and your power supply;

shielding, twisting, or otherwise treating the last six feet of cable for superior

noise rejection makes very little difference to the exposure of the line to

noise.

In the highly unusual situation where high-frequency noise is somehow making its way into the signal path through a power cord entry point, the likeliest solution to the problem would be simply to try to choke it at the entry point; a ferrite choke clamped to the outside of the power cord near the amplifier end, for example, might do this. Here again, however, we are talking about what may be a five-dollar, not a five-hundred-dollar or higher, solution.

Better Sound

Outside of noise rejection, what we most often see in performance claims for power cords is vague language describing subjective experience of the sound. These sorts of claims tend to be along the lines of "improved sonic coherency" and the like. Claims of this sort are awfully hard to pin down, simply because it's not easy to define what's being claimed, and the power of suggestion is quite hard to resist -- if a listener is convinced that a power cord will make his sound more "coherent," whatever precisely that may mean, it likely will sound more "coherent" to him when that cord is in use, if he knows it's being used. The protocol for pinning something like this down is, of course, experimental double-blind testing, and for whatever reason, the audiophile community seems to dislike double-blind testing with a passion.

Unfortunately, of course, it's that distaste for objective testing which makes these arguments drag on forever. If we can agree upon specific testing protocols, we can agree on what sort of result indicates that a listener can hear the difference between two things, and once we know that the subjective result is real and not merely the product of suggestion, the next stage in engineering the best product is to figure out exactly what physical phenomenon is the cause of the change in subjective experience. Without objective guidance, it's not only hard to know whether a phenomenon is real, but it's also hard to know how to accurately characterize, understand, and design for it. Without a doubt, if we knew how to build a power cord that would improve the sound of every system it was attached to, we'd be deeply committed to the pursuit of the best power cords in the world, but there are good reasons in principle to doubt, and little evidence in practice to confirm, that any such Philosopher's Stone cable exists, or can exist.

One thing that is fair to say is that if a cord could, in some particular application, make the sound more "coherent" or "clean" or "musical" or "splunge," the effect would as likely as not be highly idiosyncratic. One could not assume that conditions of power delivery which made for greater "coherence" on one amp would be the same conditions which resulted in such an effect on another. We can say dependably that, for example, some large amount of capacitance on an interconnect in a system with known impedances will cause a certain amount of rolloff of high frequencies, but we can't really dependably tell what, say, subtly altering the waveform of the incoming power -- if indeed a power cord were shown to do that -- would do. It might well affect the sound of some amp while not affecting others, and might affect the sound of two different amps very differently, depending upon their power-handling characteristics. The vastly greater likelihood, however, is that anecdotally-observed differences between power cords have more to do with psychology than with engineering.

So, are People who Hear Differences Between Power Cords Crazy or Stupid?

Arguments

about cable seem to make people awfully angry, and there is a tendency in these

arguments for people to up the ante by assuming that those who assert that

there are no benefits to be had from boutique products are, implicitly,

asserting that the proponents of those products are stupid, dishonest, crazy,

or, worst, deaf. So, let's be clear: not

only are those who believe in these sorts of fancy-schmancy power cords NOT

deaf, stupid, dishonest or crazy, but we'll go one further: we believe that

they hear what they say they hear. We

simply don't believe that the differences they hear objectively exist.

Arguments

about cable seem to make people awfully angry, and there is a tendency in these

arguments for people to up the ante by assuming that those who assert that

there are no benefits to be had from boutique products are, implicitly,

asserting that the proponents of those products are stupid, dishonest, crazy,

or, worst, deaf. So, let's be clear: not

only are those who believe in these sorts of fancy-schmancy power cords NOT

deaf, stupid, dishonest or crazy, but we'll go one further: we believe that

they hear what they say they hear. We

simply don't believe that the differences they hear objectively exist.

Listening is a funny thing. It is, like taste or smell, something that our brains do with information from the outside world. Importantly, it is indeed in our brains, not in our ears, where mysterious things like "enjoying music" actually happen. Our ears may report to the brain exactly what they hear, but the brain really never hears the same darned thing twice. If you listen to a track, and then are asked to listen again but pay close attention to the oboe player, you don't merely listen to it differently; you actually hear it differently. Your ears receive the same vibrations, but your brain does not do the same things with it. As the synthesis of neurology and psychology continues, these things are being studied more and more--hence the field now known as "psychoacoustics" which studies not just how our ears work but how we hear.

Our expectations, our moods, our volition, our personalities--all of these are a part of our experience of listening to music, and even a trained critical listener can have a very, very difficult time telling when something has changed. As a result, those interested in truly, scientifically isolating the impact of particular pieces of equipment and studying them use trained listeners in blind testing. Harman-Kardon, in particular, has invested heavily in listening laboratories, which are genuinely useful for studying the impact of things like speaker choice and placement.

Listening is subjective, but the rigorous study of listening must, of necessity, be objective. It's not hard to see how psychology inserts itself into the non-blind "auditioning" of high-end power cords, and far from denying the validity of anyone's experience, we are inclined to think that those who believe in these products do hear what they think they hear. The question, however, from an engineering perspective, and the question from the perspective of a person asking whether these products will confer any value to him is not what others subjectively experience, but what the impact upon the actual, physical sound is, and there just is no good basis for thinking that high-end power cords do, or can, improve the sound of an audio playback system.

Conclusion: Keep it Simple

It's clear that a well-made power supply is made to run well off of the current that comes from the wall socket, and that no power cord of reasonable design and gauge does anything to that current which is of any interest at all from an audio quality standpoint, testimonials and subjective experience to the contrary notwithstanding. This does not mean that power cords are irrelevant to audio and video quality in every case, but it does mean that there is very little that a power cord needs to do to deliver flawless performance, and it does mean that exotic designs and materials are wholly irrelevant to whether it does so.

What should one look for in a power cord? There are a few things:

- Mechanical reliability -- a sturdy design guards against intermittency and is always an aid to safety;

- UL Listing -- there is no better assurance of a cord being well-designed against the hazards of shock and fire, when used for current levels within its rated limits; and

- Adequate Gauge -- a power cord should not cause significant voltage drops at the load and should not run the risk of starving the power supply for current at peak demand.

None of these things, however, should cost an arm and a leg. When you see extraordinary claims made for power cords, it's time to step back and look for something simple, sturdy, well-sized and UL Listed at a reasonable price.

Article Epilogue

While many

exotic cable companies sell a nice story in attempt to convince unwary

consumers that their products are better than their competition, we appreciate

the candor Blue Jeans Cable always exhibits. In

a market flooded with questionable claims, overhyped and overpriced products,

it's refreshing to find a company that doesn't follow such a business

model. Truth has become a marketable

commodity and as long as Blue Jeans Cables continues to produce quality

affordable products without the marketing nonsense, they will continue to be

our #1 recommended cable manufacturer to our readers. Kudo's to Blue Jeans Cables and to our readers for educating

themselves and steering clear of the marketing nonsense others like to spew as

religion. As long as you remember our

mantra, "only poorly designed cables can be sonically distinguishable" or "properly designed cables are sonically indistinguishable" when shopping cables, you will never make a

bad purchasing decision. We leave it up to the reader to decide if they can't trust a cable manufacturer or A/V review publication on a topic as simple as power cords, how they can trust them on more important things such as hardware product reviews or complex subject matter related to home theater and technology.

Many thanks to Blue Jeans Cables for co-authoring this much needed article regarding Power Cables.